|

Product Name |

Excavators buckets made of thickness 10+10 wear resistant clad plates used in mining |

|

Brand |

WODON |

|

Annual Output |

|

|

Base Metal |

Q235/Q345 or other medium or low carbon steel or stainless steel |

|

Surfacing Overlay |

High chromium high carbide |

|

Chemical Composition |

C(%): 3.0-5.0 ,Cr(%): 25-40 |

|

Metallographic Structure |

The carbide (Cr7C3) volume fraction on the microstructure is above 50% |

|

Hardness |

HRC58-65 |

|

Wear Resistance |

Our test shows that the wear resistance of WODON plate is 20 times higher than low carbon steel and 8 times than heat treated steel |

|

Impact Resistance |

WODON wear plates can withstand medium impact |

|

Flatness Tolerance |

Flatness tolerance is ±3mm/m |

|

Thickness Tolerance |

Uniform overlay thickness, tolerance within 0-0.5mm |

|

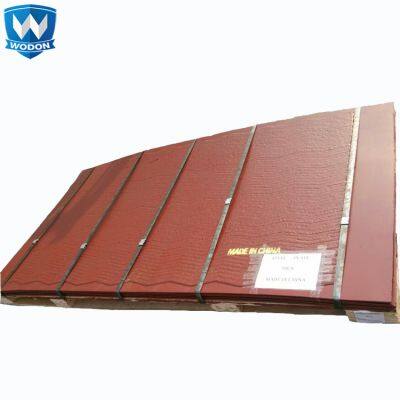

Main Thickness Base metal + overlay |

3+3, 4+4, 5+5 6+4, 6+5, 6+6, 6+8 8+4, 8+5, 8+6, 8+7, 8+8 10+4, 10+5, 10+6, 10+7, 10+8, 10+9, 10+10, 10+20 12+4, 12+5, 12+6, 12+7, 12+8, 12+10, 12+11, 12+12, 12+18, 12+20 14+6, 14+8, 14+10 16+6, 16+8, 16+10 18+6, 18+8, 18+10 20+5, 20+6, 20+8, 20+10, 30+10, 40+10, 20+20, 20+25 |

|

Size |

Width:Max 2400mm Length:Max 4000mm Customized size is acceptable |

|

Place Of Origin |

Jiangsu, China |

|

Package |

Steel Pallet or Fumigation wooden case |

|

Delivery Time |

1-10 days after order confirmed |

|

Payment Term |

EXW, FOB,CFR, CIF |

|

Port Of Loading |

Any ports of China |

|

Other Wear Resistant Plate |

1. Impact Resistant Wear Plates ---Independent R&D, with high wear and high impact resistance 2. Heat Resistant Wear Plates ---Independent R&D, with heat resistance maximum up to 900℃ 3. No Crack Wear Plates ---Hardness HRC: 50-55, mainly used in housing liner of steel mill, domestic unique product 4. Special Chemical Elements Wear Plates ---Customized, Chemical elements: Mo, Nb, Ni, W, V, etc. |

Production Process

Welding process is the use of the most advanced open arc welding welding process, the various effects of this process on the performance of a very small base , and wear to maximize play. Composite wear plate is ordinary steel (Q235 (A3) or heat-resistant steel (15CrMo, 12Cr! MoV , etc. ) , stainless steel plate formed on the entire volume fraction of more than 50% Cr7C3 carbide -based wear layer , which with high wear resistance , impact resistance, deformable and welding performance, like steel , like direct texturing , cutting and drilling and other processing sectors , processed into mining engineering components to meet the wear and put into use . wear-resistant material with many compared wear-resistant composite plate has its irreplaceable notable features.

We are specialized in researching, developing and producing wear resistant products with many years experience in this field. We have more than 180 employees, with an annual output of 90,000 square meters of wear plates and 9,000 tons of welding consumables.

Why our wear plate has such good wear resistance?

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

45 minutes for each specimen.

|

No. |

Wear Plate Type |

Test Time |

Weight Loss of Overlay |

|

1 |

Wodon Wear Plate |

45 minutes |

0.148g |

|

2 |

Imported Wear Plate |

45 minutes |

0.229g |

|

3 |

Imported Wear Plate |

45 minutes |

0.237g |

|

4 |

Imported Wear Plate |

45 minutes |

0.252g |

|

5 |

Domestic Wear Plate |

45 minutes |

0.385g |

|

6 |

Domestic Wear Plate |

45 minutes |

0.377g |

|

7 |

Domestic Wear Plate |

45 minutes |

0.399g |

|

8 |

Domestic Wear Plate |

45 minutes |

0.371g |

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the carbide (Cr7C3) volume fraction on the microstructure is above 50%.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

Using our wear resistant plate as raw material, WODON wear parts are nice looking and with excellent wear resistant strength. Quality of WODON wear parts is one of the best among peers. We produce wear parts like Vertical Mill, Roller Press, Wear Resistant Table Liner, Cement Grinder, Mill Grinder, etc. Our wear parts are available to be cut and profiled by Laser Cutting, Plasma and High Pressure Water Abrasive Cutting according to customer's requirements.

Since 2004, Wodon has more than 200 employees.

Wodon product: flux cored welding wires, chromium carbide overlay steel plates, wear resistant partss, wear pipes, wear fittings.

Welding wire and wear plate workshops

Wodon's quality managment

Warehouse

Q: Are you trading company or manufacturer ?

A: We are ISO certified flux cored welding wire and CCO wear plate factory.

Q: Are you able to produce customized chemical composition and dimension?

A: Yes, we could offer special welding wire and wear plate according customers' requirement.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 20~30% T/T in advance, balance against the copy of BOL. Other payment terms are negotiable.

Q: Do you provide after-sales service ?

A: Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

If our product meets your interest, please feel free to contact us as follow:

Send Inquiry to This Supplier

You May Also Like

-

Hardfacing Bimetal Steel Plate Wear Resistant PlateUS$ 256 - 256MOQ: 1 Square Meter

-

Wear Abrasion Resistant Overlay High Carbon High Chromium Steel PlateCAD 256 - 256MOQ: 1 Square Meter

-

High Hardness 58~65 Abrasion Resistant Super Hardened Overlaying Steel PlateUS$ 170 - 170MOQ: 1 Piece

-

Wodon Manufactured Premium Chromium Carbide Cladded Steel With Super Wear ResistanceCHF 300 - 300MOQ: 1 Square Meter

-

High CCR Clad Liner Plate Wear-Resistant Pads With Q345 Steel Base Dragline Bucket With Bending Processing ServiceUS$ 120 - 120MOQ: 1 Square Meter

-

Hardfacing Cladding Abrasion Resistant Plate High Hardness Anti Friction Wear PlateUS$ 180 - 180MOQ: 1 Piece

-

ASTM G65 Good Quality CCO Wear Resistant PlateCHF 256 - 256MOQ: 1 Square Meter

-

Super Hardened Cast Hardfacing Wear Resistant Lining Plate for Dragline Bucket Inside InstallUS$ 120 - 120MOQ: 1 Square Meter

-

High Strength Bimetallic Wear Resistant Overlay PlateCHF 256 - 256MOQ: 1 Square Meter

-

Composite Wear Plate Wear Resistant Steel Plate Wear Plate for BucketUS$ 400 - 400MOQ: 1 Square Meter