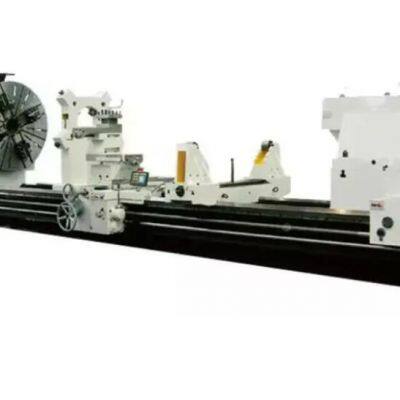

CNC Heavy Duty Horizontal Lathe(Guideway Width: Max.3500mm)

Feature of CNC Heavy Duty Lathe

1. The CNC Heavy Duty Lathe is our self-developed products, using CAD design, spindle box for the whole box structure. The main drive system is transmitted from the frequency converter motor and frequency converter to the spindle box by the belt.

2. The front and rear bearings of the headstock spindle adopt high-precision (SP level) double-row roller bearings and high-precision plane thrust roller bearings.

The spindle and tailstock top adopts short shafts to match with each other, which is installed in the center of the spindle and linked with the spindle to make the spindle of the headstock box a body.

3. The spindle and tailstock center is mounted on the spindle center and connected with the spindle to form a body, which makes the spindle of the headstock have the best rigidity and bearing capacity, high rotary accuracy and easy to dismantle and maintain.

4 It is easy to dismantle and repair. The headstock increases the hydraulic gearshift device and oil circuit detection alarm, which makes the operation of the machine tool gear simple and ensures the smoothness of the oil circuit of the machine tool.

5. Ensure the smoothness of the oil circuit of the machine tool.

Parameter of CNC Heavy Duty Lathe

Advantage of CNC heavy duty lathe

1. High precision: CNC heavy-duty horizontal lathe adopts advanced CNC technology, which can achieve high precision machining and ensure the quality and precision of machined parts.

2. High efficiency: the lathe has the ability of high-speed cutting and fast feeding, which can greatly improve the machining efficiency and save production time.

3. High power: CNC heavy-duty horizontal lathe is usually equipped with a high-power spindle, which can adapt to the processing of various hardness of the workpiece and improve processing efficiency.

4. Good stability: CNC heavy-duty horizontal lathe has a stable structure and is made of high-quality materials, which have good wear resistance and stability and can run stably for a long time.

5. One-piece bed casting

6. Using a hydraulic station, but not only a hydraulic pump

Send Inquiry to This Supplier

You May Also Like

-

CNC Vertical Lathe With C Axis for Turning, Milling, Boring, TapperingNegotiableMOQ: 1 Set

-

CK6180 Heavy Duty Horizontal CNC Metal Lathe Machine for SaleNegotiableMOQ: 1

-

Horizontal Tensile Test Machine Price Custom Horizontal Tensile Testing System Heavy Duty Tensile Test EquipmentUS$ 7000 - 15000MOQ: 1 Set

-

JUNTUO-GJC Heavy Duty CNC Tool Cart With Lockable Drawers for Machine Shop EfficiencyUS$ 99 - 269MOQ: 2 Cases

-

Versatile CNC Milling Parts Stainless Steel/Brass/Alloy Steel Suitable for Heavy-Duty Industrial & Manufacturing UseUS$ 14MOQ: 10 Units

-

Fanuc A06B-6141-H022#H580: Your CNC Spindle’s Quiet Powerhouse for Heavy-Duty CutsUS$ 1300.00MOQ: 1 Blade

-

Wholesale Galvanized 24\"x96\" Heavy Duty Carbon Steel Diamond Metal Lath Modern for Industrial Use for Stucco Walls FloorsUS$ 1.7 - 3.2MOQ: 1 Piece

-

Heavy Duty Cnc Lathe CJK6180 Large Duty Cnc LatheUS$ 10,000 - 85,000MOQ: 1 Set

-

Our Equipment Sweden CNC Double Column Vertical Lathe 10M-heavy-duty-lathe-Load-220TUS$ 1,500 - 6,000MOQ: 1 Tonne

-

China Machinery Parts Manufacturers/Suppliers Heavy Duty Cnc Machining Lathe Machine Spare Part Milling/turning ServicesUS$ 1 - 100MOQ: 1 Piece