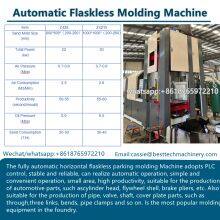

1100*1000mm Automatic Sand Molding Machine for Manhole Cover Production

Green Sand Automatic Flaskless Moulding Line

Pneumatically feeds moulding sand in vertical direction, has the best filling performance and completely improve the shadow defect caused by horizontal shooting sand. Simple process,convenient moulds and pouring gate, high product rate and strong applicability.

The user can choose the casting height and compaction pressure under different castings flexibly to ensure the reasonable use of moulding sand.

Template installation: fixedy by four screws, the replacement is completed within five minutes, and the mold is changed frequently.

The fault is displayed on the touch screen, and the fault reason is displayed on the touch screen. The user can easily find the fault and take measures.

The hydraulic, pneumatic and electrical components all adopt imported components to ensure the stable and reliable operation of the equipment and the service life.

All types of equipment manufactured by the company adopt a stable and reliable safety defense system.

With servo hydraulic system, the supply pressure of the system can be adjusted automatically according to the various stages of the equipment operation, reducing the loss of energy.

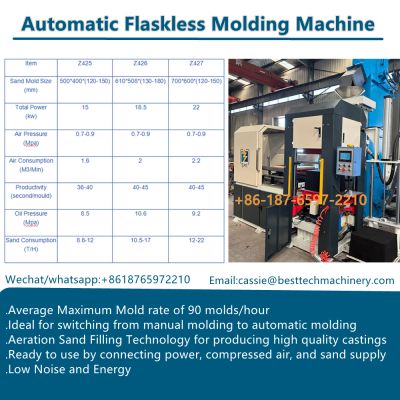

technical parameter:

Parameter | XGA-01 | XGA-02 | XGA-03 |

Sand Mould Size (LxWxH) | 500x400x(120~150)

| 610x508x(130~180) | 700*600(120-150) |

Mould Way | Injection and Compaction | Injection and Compaction | Injection and Compaction |

Compaction specific pressure | ~1.0Mpa | ~1.0Mpa | ~1.0 Mpa |

Power Mode | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure |

Max productivity | 40s/mould(Excluding core setting time) | 40s/mould(Excluding core setting time) | 40s/mould(Excluding core setting time) |

Our Service:

1. Reply your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. Customized design is available. UEM&UBM are welcomed.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Special discount and protection of sales are provided to our distributor.

6. Professional factory : We are manufacturer, specializing in producing all kinds of machinery for more than 20 years, competitive with good quantity.

7.Sample: We can send out sample for test in one week if the order quantity is big enough. But the shipment charges is usually paid by your side, the charges will be rebounded when we have formal order.

8.As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company.

Q:How many days will be used to produce this sand molding machine?

A:Normally within 15 workdays or according to your requirement

Q:Can you provide installation and commissioning overseas?

A:We can supply oversea service if needed

Q:Are you manufacture or trading company?

A:We are manufacture,welcome to visit our factory

Send Inquiry to This Supplier

You May Also Like

-

Foundry Green Sand Molding MachineUS$ 2000 - 20000MOQ: 1 Set

-

Foundry Grinding Wheel Clay Sand MixerUS$ 2000 - 20000MOQ: 1 Set

-

Foundry Single Arm Furan Resin Sand MixerUS$ 2000 - 20000MOQ: 1 Set

-

Foundry Double Arm Resin Sand MixerUS$ 2000 - 20000MOQ: 1 Set

-

Hydraulic Sand Molding MachineUS$ 2000 - 20000MOQ: 1 Set

-

Horizontal Flaskless Sand Molding MachineUS$ 2000 - 50000MOQ: 1 Set

-

Vertical Flaskless Sand Molding MachineUS$ 2000 - 50000MOQ: 1 Set

-

Cold Box Sand Core Shooter for Brake DiscUS$ 2000 - 20000MOQ: 1 Set

-

Hot Box Sand Core Shooting MachineUS$ 2000 - 20000MOQ: 1 Set

-

Foundry Sand Core Shooter for Production ValvesUS$ 2000 - 20000MOQ: 1 Set