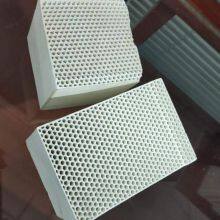

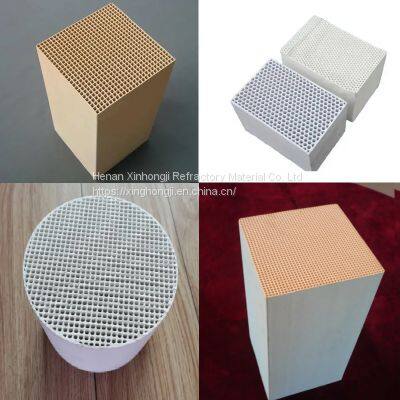

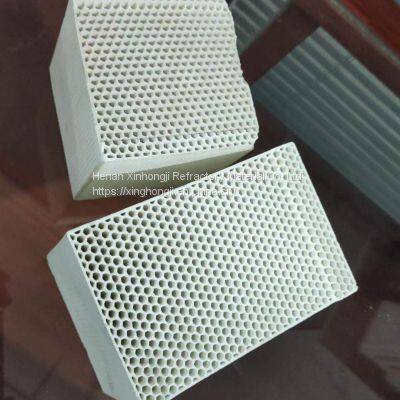

Top Quality High Alumina Ceramic Refracotry Thermal Insulation Honeycomb Heat Regenerator

Refractory Honeycomb Ceramic Regenerator

Introduction

Refractory Honeycomb Ceramic Regenerator (also called Ceramic Regenerator, or Refractory Ceramic Block), Honeycomb Ceramic Regenerator is the main components of High Temperature Air Combustion Technology. It has been widely used in various heating furnaces such as pusher-type heating furnace, walking-beam heating furnace, heat treatment furnace, forging furnace, melting furnace, firing furnace and ladle heaters, soaking pit, radiant tube burner, lifting furnace, blast furnace hot blast stove etc.

Honeycomb ceramic regenerator is a kind of porous ceramics. The regenerator is the key component to stop heat and reduce harmful gas emission. It is widely applied in all kinds of HiTAC (High temperature air combustion) step-type heating furnaces, RTO (Regenerative thermal oxidizer) Etc. we can produce honeycomb ceramic regenerators with many kinds of raw materials, such as cordierite, mullite, corundum-mullite, Carborumdum, Zr-Cr corundum etc. Advantages of ceramic regenerator can improve heat exchange condition in the furnace, utilize low calorific value fuel. Reduce the heat loss, utilize the energy to the most, and reduce operation capital. Reduce harmful gas emission, produce more friendly.

Features

1. Various materials, according to customers and different environments, choose different materials and specifications of products.

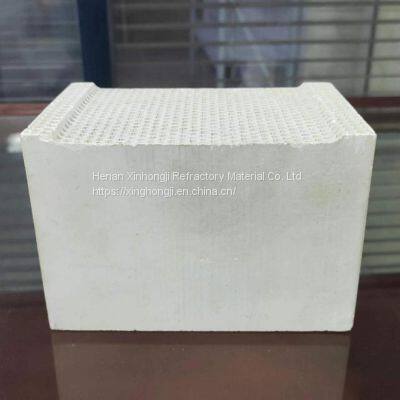

2. The hole wall is thin, the capacity is large, the heat storage is large, and the space is small.

3. The hole wall is smooth and the back pressure is small.

4. Long service life, not easy to scum, high temperature deformation after drinking.

5. The product has high quality specifications. During installation, the heat storage bodies are discharged neatly with little misalignment.

6. Good thermal shock resistance, good thermal conductivity, and high mechanical strength.

Chemical & Physical Index

Material | Loose Cordierite | Dense Cordierite | Cordierite Mullite | Mullite | Corundum Mullite | |

Chemical Composition | Al2O3, % | 33-35 | 35-37 | 33-35 | 59-61 | 69-72 |

SiO2, % | 48-50 | 48-50 | 48-51 | 35-38 | 25-28 | |

Fe2O3, % | 1.6 | 0.80 | 0.90 | 0.75 | 0.70 | |

Thermal Expansion | (Room Temp. -1000%)×10-6/℃ | 1.5-1.8 | 2-2.5 | 2.0-3.0 | 4.2-5.0 | 4.5-5.2 |

Thermal Capacity | (Room Temp. -1000℃), J/kg | 750-900 | 800-1200 | 1100-1300 | 1100-1300 | 1300-1400 |

Bulk density | (g/cm3) | 0.5~0.8 | 0.6~0.9 | 0.6~1.1 | ≥0.8 | |

Compressive Strength | (MPa) (C axis) | ≥20 | ||||

Thermal Shock Resistance ℃ | 300 | 250 | 300 | 230 | 260 | |

Softening Temperature℃ | 1280 | 1350 | 1400 | 1630 | 1680 | |

Refractoriness ℃ | 1360 | 1410 | 1480 | 1750 | 1790 | |

Max Service Temperature | 1200 | 1300 | 1350 | >1550 | >1600 | |

HS CODE NO | 6914100000 | |||||

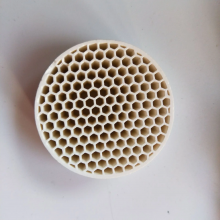

Ceramic honeycomb channel number and shape

No | Dimension | Channel shape | Number of channels |

1 | 150 × 150 × 300 | Square | 40 /150mm |

2 | 150 × 150 × 150 | Square | 40 /150mm |

3 | 150 × 150 × 100 | Square | 40 /150mm |

4 | 150 × 150 × 300 | Square | 25 /150mm |

5 | 150 × 150 × 150 | Square | 25 /150mm |

6 | 150 × 150 × 100 | Square | 25 /150mm |

7 | 150 × 150 × 100 | Square | 30 /100mm |

8 | 100 × 100 × 50 | Square | 30 /100mm |

9 | 100 × 100 × 100 | Square | 27 /100mm |

10 | 100 × 100 × 50 | Square | 27 /100mm |

11 | 100 × 100 × 100 | Hexagonal | 30 /100mm |

Size Types:

l 200x100x100mm / 150x 100x100mm / 150x 150x100mm / 100x 100x100mm

l Customized

Characteristics:

Honeycomb Ceramic Regenerator has low heat expansion, high specific heat capacity, high specific surface area, low pressure drop, low thermal resistance, good thermal conductivity, thermal shock resistant and much more. So, in metallurgy and chemical industries, it’s used as HTAC, while we combine recycling the heat of the emissions, high efficient combustion with reducing NOx. It becomes a true energy saver and decreases Nox.

Application :

Iron and steel plants, waste incinerators, waste gas treatment thermal equipment, chemical plants, smelters, power plants, power industry boilers, gas turbines, engineering heating equipment, ethylene cracking furnaces, etc.

Package

1 ) . Carton + Wooden pallet

Send Inquiry to This Supplier

You May Also Like

-

Good Thermal Shock Resistant High Alumina Andalusite Brick Refractory BricksUS$ 600 - 800MOQ: 1 Ton

-

Low Cement High Temperature Fire Proof High Acid Resistance Mullite Refractory CastablesUS$ 450 - 600MOQ: 1 Ton

-

Low Density Lightweight Insulating Refractory Castable High Alumina Insualtion CastablesUS$ 190 - 250MOQ: 1 Ton

-

Calcined Diaspore Clay Flint Clay Bauxite Ore Aggregate High Alumina Raw Materials for RefractoriesUS$ 200 - 300MOQ: 1 Ton

-

Wholesales Calcined Cordierite Ore High Alumina Raw Materials Aggregate BauxiteUS$ 180 - 260MOQ: 1 Ton

-

Wear Resistance Special Burned Phosphate Bonded High Alumina Refractory BricksUS$ 500 - 700MOQ: 1 Ton

-

Blast Furnace Refractory Lining FireBricks Low Creep High Alumina Refractory BricksUS$ 290 - 490MOQ: 1 Ton

-

Acid Resistance Firebricks Acid-Resistant High Alumia Refractory BricksUS$ 400 - 600MOQ: 1 Ton

-

Customizable Fireclay Brick Low Creep Refractory Fire Clay Bricks for Bast Furnaces / StoveUS$ 250 - 350MOQ: 1 Ton

-

Wholesales Glass Furnace Silicon Quartzite Blocks Silicate Refractory Silica BricksUS$ 300 - 650MOQ: 1 Ton