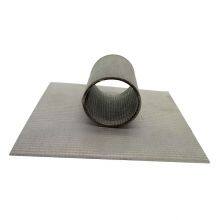

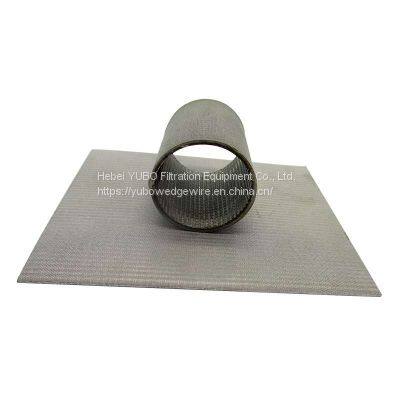

The cylindrical stainless steel cartridge is a type of filter element. Made of stainless steel as raw material and sintered as the core process.

Structure and process of cylindrical sintered filter cartridges

1. Structure: 5 - 7 layers of woven or perforated stainless steel wire mesh overlapped.

2. Process: Vacuum sintering technology.

Benefits

The 5 layers of stainless steel wire mesh are sintered together to offer a very fine micron filtering, acid, and alkali corrosion resistance, high-temperature resistance (temperature up to 480 °C), etc. Penetration and work durability are also excellent.

Application areas

Suitable for petroleum, chemical, mining, food, pharmaceutical, coating, and another filter from all walks of life.

Leave a comment on the website or email us to describe your filtering requirements! E-mail: sales@yubofilter.com

Send Inquiry to This Supplier

You May Also Like

-

Filter Housing and Solution for Gas FiltrationNegotiableMOQ: 1 Set

-

Screen Basket for Paper MakingUS$ 1 - 200MOQ: 1 Set

-

Stainless Steel Screen Nozzles-wedge Wire ProductsUS$ 1 - 50MOQ: 10 Sets

-

Polyurethane Vibrating Screen Panels|polyurethane ScreensUS$ 1 - 200MOQ: 1 Square Meter

-

Ion Exchange Nozzles for Intermediate PlateUS$ 1 - 10MOQ: 10 Sets

-

Johnson ScreenUS$ 1 - 500MOQ: 1 Set

-

Mash Tun False Bottom for Sale at Best PriceUS$ 1 - 500MOQ: 1 Set

-

Wedge Wire Filter, Johnson Screen | High-Strength FiltrationUS$ 10 - 1000MOQ: 10 Sets

-

Stainless Steel Wedge Wire Filter Nozzle for Water TreatmentUS$ 3 - 40MOQ: 10 Sets

-

Perforated Strainer BasketNegotiableMOQ: 1 Piece