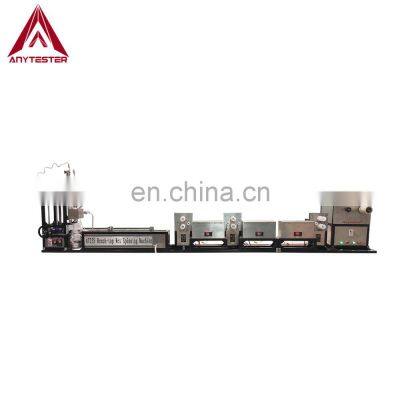

Bench-Top Wet Spinning Machine

Model | AT235 | ||

Spinning solution tank | 1L or customized 316L stainless steel Rapid-mount cover With Nitrogen inlet port and vent port | ||

Sample volume | 200~ 600ml or customized | ||

Dosing pump flow rate | 0.66CC/rev | ||

Dosing pump power | 180W | ||

Dosing pump reducer | 1:59 | ||

Gooseneck material | 316L stainless steel | ||

No. of spinneret | 1 | ||

Spinneret nut | 100 holes, hole dia.: 0.07mm Material: tantalum | ||

Coagulating bath | Inner size | 1000×160×160mm (L×W×H) | |

Material | 316L stainless steel | ||

Drawing roller | Material | Nylon | |

Size | Ø50×80mm | ||

Reducer | 1:5 | ||

Motor power | 120W | ||

Roller speed | 3~40m/min adjustable | ||

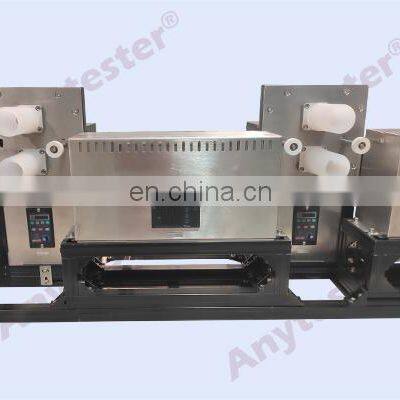

Heating bath | Type | non-contact | |

Length | 400mm | ||

Heating power | 250W | ||

Temp. range | Room temperature~150℃ | ||

Sensor | PT100 | ||

Setting bath | Type | non-contact | |

Length | (400×2)mm | ||

Heating power | 250W×2 | ||

Temp. range | Room temperature~150℃ | ||

Sensor | PT100 | ||

Winder | Speed | 3~40m/min | |

Size | Ø95×80mm | ||

Transverse displacement | 60mm | ||

The Whole line length | 4200mm | ||

Power supply | AC220 50Hz, single-phase | ||

Pakeging | ||

pakeging Details | 1. The equipment is covered with film is protect it from water vapour during the trip. 2. The box is filled with foam to protect the equipment from impact. 3. Exported wooden box made from plywood, don't need fumigated. | |

Title goes here.

Title goes here.

Title goes here.

Send Inquiry to This Supplier

You May Also Like

-

Laser Shaft Alignment Tool Heat Press Laser AlignmentNegotiableMOQ: 100 Pieces

-

Programmable Reverse Torsion Tester Automatic Wire Torsion Testing System Wire Torsion Tester With CounterUS$ 4000 - 6000MOQ: 1 Set

-

Hydraulic Plastic Flange Connections Cover Plugs SHF SeriesUS$ 0.22 - 0.28MOQ: 2500 Pieces

-

Impact Testing MachineUS$ 950 - 1350MOQ: 1 Piece

-

Gates 550C 550U U550 U-550 U508 U-508 Japan Unitta U-550 Belt Tension Meter New U-508 Belt Tension Meter Upgraded Version U550US$ 1 - 900MOQ: 1 Piece

-

Plastic Packaging Film Heat Seal Tester/Laboratory Heat Sealer / Five Points Heat Seal TesterUS$ 9,500 - 10,000MOQ: 1 Set

-

Diesel Fuel Injection Pump Test Bench Simulator System Control InstrumentUS$ 200 - 300MOQ: 1 Set

-

Analytical Balanace.scale ,weichengya Laboratory SupplierUS$ 10 - 35MOQ: 10 Sets

-

Smart MD-3051 Online Density Meter With 4-20mA OutputUS$ 2,380 - 2,500MOQ: 1 Unit

-

5W-300W Sun Simulator Watt Testing 30% Off / Xenon Lamp Sun Simulator Free Sent / Sun Simulator TestingUS$ 7,500 - 10,000MOQ: 1 Set