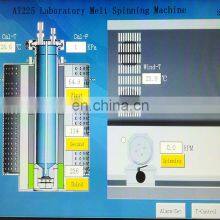

Model | AT225 | |

Pressure range | Max. 2MPa (can extend to 3.6Mpa) Input pressure: ≤13MPa, Output pressure: ≤1.5MPa accuracy: ±0.01MPa | |

Temperature range | Max. 350℃ | |

Temperature accuracy | ±0.5℃ | |

Heating mode | Three heating sections with copper ring block to heat Mullite fiber insulation | |

Temperature control mode | Three independent temperature controlling with the accuracy of ±0.5℃ | |

Feed cylinder | 500ml, stainless steel, with soaking distribution device | |

Spinneret plate | Dia. 0.15~0.5mm L: D: 2:1~3:1 1~20 spinneret holes (please specify before order) | |

Winding system | ||

Winding roller drive mode | Motor-driven | |

Speed range | 0~1400rpm, adjustable | |

Winding roller diameter | ¢200mm, can be customized | |

Max. Winding dia. | ¢320mm (including ¢200mm winding roller) | |

Power supply | AC220V, 50Hz | |

Dimensions | 870mm×1310mm×1860mm (D×W×H) | |

Weights | Approx. 320kg | |

No. | Item | Quantity |

1. | Main machine | 1set |

2. | Spinneret plate (on main machine) | 1pcs |

3. | Winding roller (on main machine) | 1pc |

4. | Distribution plate (on main machine) | 1pcs |

5. | Filtering plate | 10pcs |

6. | Gas inlet pipe | 1pcs |

7. | Special spanner | 1pcs |

8. | Temperature sensor | 1pcs for spare |

9. | Packing list | 1pc |

10. | Quality certificate | 1pc |

11. | User manual | 1pc |

No. | Item |

1 | Spinneret plate |

2 | Winding roller |

3 | Filtering plate |

4 | Temperature sensor |

Pakeging | ||

pakeging Details | 1. The equipment is covered with film is protect it from water vapour during the trip. 2. The box is filled with foam to protect the equipment from impact. 3. Exported wooden box made from plywood, don't need fumigated. | |

Send Inquiry to This Supplier

You May Also Like

-

Computerized Universal Testing Machine With Extensometer 50knUS$ 4500 - 10000MOQ: 1 Set

-

Laser Shaft Alignment Tool Heat Press Laser AlignmentNegotiableMOQ: 100 Pieces

-

Hydraulic Plastic Flange Connections Cover Plugs SHF SeriesUS$ 0.22 - 0.28MOQ: 2500 Pieces

-

Impact Testing MachineUS$ 950 - 1350MOQ: 1 Piece

-

Gates 550C 550U U550 U-550 U508 U-508 Japan Unitta U-550 Belt Tension Meter New U-508 Belt Tension Meter Upgraded Version U550US$ 1 - 900MOQ: 1 Piece

-

Plastic Packaging Film Heat Seal Tester/Laboratory Heat Sealer / Five Points Heat Seal TesterUS$ 9,500 - 10,000MOQ: 1 Set

-

Diesel Fuel Injection Pump Test Bench Simulator System Control InstrumentUS$ 200 - 300MOQ: 1 Set

-

Analytical Balanace.scale ,weichengya Laboratory SupplierUS$ 10 - 35MOQ: 10 Sets

-

Smart MD-3051 Online Density Meter With 4-20mA OutputUS$ 2,380 - 2,500MOQ: 1 Unit

-

5W-300W Sun Simulator Watt Testing 30% Off / Xenon Lamp Sun Simulator Free Sent / Sun Simulator TestingUS$ 7,500 - 10,000MOQ: 1 Set