Automatic Liquid Honey Blister Packaging Machine With Easy Operation

Product Name | DPP-320 Automatic Blister Packing Machine | ||||||

Blanking frequency (sheets): | 15-60 | ||||||

Sheet's quantity of one blanking (sheets): | 1-6 | ||||||

Capacity (sheets/hour): | 1800-18,400 | ||||||

Adjustable scope of feed travel: (mm) | 10-160 | ||||||

Max Forming area and depth (mm) PVC (For medicine): | 340×120×25 | ||||||

Capacity of air compressor(m3/min): | ≥0.36 | ||||||

Power supply (KW): | 380V 50Hz Three phase | ||||||

Wrapper specification (mm): | PVC for medicine 340× (0.15-0.5) mm Aluminum film 340× (0.02-0.035) mm | ||||||

Weight (kg): | 2100Kg | ||||||

2.Mould is located by locating groove which makes it easy to change mould. The machine heats the PVC through conduction and forms it through pressing and frothing.

3.The material is fed automatically. The mould and feeder can be designed as user’s requirements.

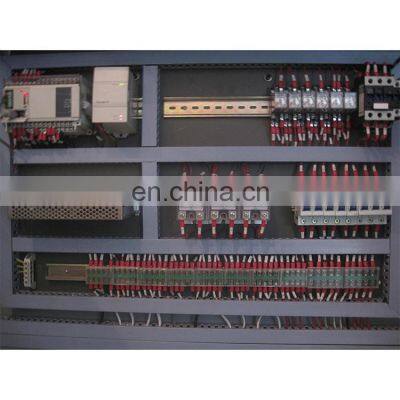

4.Speed is shifted by step-less transducer. Adopt the interface of human-machine and PLC programmable controller, it can synchronize accurately.

5.Adopt the equipment of trace pressing, batch number printing and scarp-collecting.

6.Stepping motor drives and tow materials.

7.The heating moulds will automatically separate when the machine stops, which contributes to protect the material between them and extend the machine’s life.

Send Inquiry to This Supplier

You May Also Like

-

Plastic Blister Packaging Machine for Flashlight,batteries, Spark,lipsticks,facial MasksNegotiableMOQ: 1 Set

-

11 Liquid Blister Packing MachineUS$ 8,000 - 15,000MOQ: 1 Set

-

New Design Automatic Blister Packing MachineUS$ 3,999 - 4,999MOQ: 1 Set

-

2015 Mascara Lady's Shaver Eyebrow Pencil Paper Plastic Blister Packing MachineUS$ 45,000 - 50,000MOQ: 1 Set

-

Dession Semi Automatic Tablet Packing Machine Blister Heat Sealing Machine for Blister PackingNegotiableMOQ: 1

-

Fully Automatic Ketchup Blister Packaging Machine For Ketchup Into Plastic Contain Ketchup Cup Packing MachineNegotiableMOQ: 1

-

Blister Cutting MachineNegotiableMOQ: 1

-

400mm Packing Width Custom Blister Packaging MachineNegotiableMOQ: 1

-

KSP-800/1000/1200C/D Fully Automatic Capsule Filling MachineNegotiableMOQ: 1 Set

-

DPP-250 Automatic Blister Packing Machine Price With Blister Packing Machine MouldNegotiableMOQ: 1