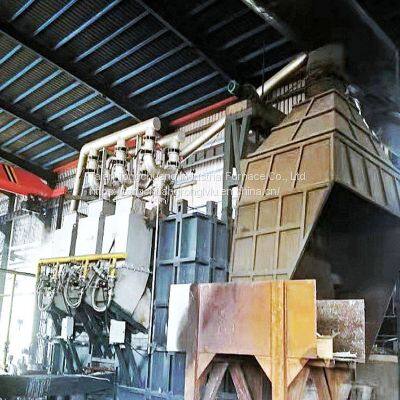

The Rotary Copper Melting Furnace, Supplied by the Manufacturer, Has Fast Temperature Rise

Copper smelting furnace, medium frequency electric furnace, the power supply is 80~2500kkw, the melting capacity is 0.05t-5t, and the efficiency is high.

At present, the copper smelting furnaces required in the market are generally based on their process requirements (for raw materials and product quality). Commonly used red copper and brass or copper alloy as raw materials. After the copper is melted, common products are copper rods, copper ingots, copper bars, and electronic product parts. Generally speaking, factories that use a small amount of copper or factories that do not have high requirements on the quality of copper products can use small copper to melt the converter.

Before starting the copper melting furnace, it is necessary to check whether the electrical equipment, the water cooling system, and the copper tube of the inductor are in good condition, otherwise it is forbidden to open the furnace. Secondly, if the melting loss in the furnace exceeds the specification, it should be repaired in time. It is strictly forbidden to smelt in a crucible with too deep melting loss. A special person should be designated to be responsible for power transmission and furnace opening. Do not touch inductors and cables after power has been applied. Personnel on duty shall not leave their posts without authorization, and always pay attention to the external conditions of the sensor and crucible.

When charging the copper smelting furnace, it is necessary to check whether the charge is mixed with inflammables, explosives and other harmful substances. If there is, it should be removed in time. It is strictly forbidden to add cold and wet materials directly into molten steel. After the molten liquid is filled to the upper part, it is strictly forbidden to add bulk materials to prevent capping. When repairing the furnace, it is strictly forbidden to mix scrap iron and iron oxide into the crucible, so that the crucible must be dense.

In addition, it should be noted that the pouring site and the tunnel in front of the furnace should be free of obstacles and accumulated water to prevent the molten steel from falling to the ground and explode; it is not allowed to overfill the molten steel. When moving the ladle by hand for pouring, the two should cooperate tacitly, walk steadily, and do not rush to stop. After pouring, the remaining molten steel should be poured into the designated place, and it is strictly forbidden to pour it randomly.

Send Inquiry to This Supplier

You May Also Like

-

Rotary Furnace, Rotary Furnace for Waste Aluminum Treatment, 6T Dump Rotary FurnaceUS$ 65000 - 70000MOQ: 1 Set

-

Medium Frequency Furnace Equipment, Precious Metal Refining Furnace, Copper Melting Furnace Heating up QuicklyUS$ 60000 - 65000MOQ: 1 Set

-

Small Smelting Equipment, Industrial Furnace, Heating up Fast, 5 Tons of Aluminum Melting FurnaceUS$ 65000 - 72000MOQ: 1 Set

-

Small Shredding Machine, Scrap Metal Crusher, Multifunctional Biaxial Shredding MachineUS$ 65000 - 72000MOQ: 1 Set

-

Waste Copper Melting Furnace, Delivery Quick Casting Heat Treatment, Dumping Crucible FurnaceUS$ 62000 - 66000MOQ: 1 Set

-

Tongchuang Company Supply Aluminum Alloy Melting Furnace, High Efficiency Large Natural Gas FurnaceUS$ 63000 - 66000MOQ: 1 Set

-

Processing Custom Biomass Furnace Safety and Simple Multi-specification Melting FurnaceUS$ 62000 - 67000MOQ: 1 Set

-

Aluminum Smelting Equipment, Ingot Furnace, Industrial Metal Melting Casting Aluminum FurnaceUS$ 58000 - 63000MOQ: 1 Set

-

Multi-specification Melting Furnace Crucible Furnace for Casting Heat TreatmentUS$ 62000 - 66000MOQ: 1 Set

-

Fuel Gas Aluminum Melting Furnace Environmental Protection and Energy Saving Melting UniformUS$ 63000 - 66000MOQ: 1 Short Ton