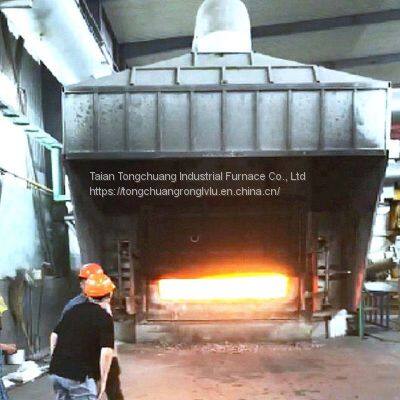

Fuel Gas Aluminum Melting Furnace Environmental Protection and Energy Saving Melting Uniform

Fuel-fired aluminum smelting furnace, that is, crucible smelting and holding furnace, is currently mainly used for smelting, casting and hot-dipping of non-ferrous metals such as aluminum, zinc, silver, lead, tin, and copper. Its main feature is the use of light diesel as fuel, clean and safe, making the workshop clean and tidy, easy to manage, low operating cost, high thermal efficiency, and very popular.

During the operation of the fuel oil melting aluminum furnace, some problems need to be paid attention to. Only in this way can the normal operation of the industrial furnace be guaranteed.

1. Before igniting the aluminum melting furnace, check whether the electrical equipment is normal. When an abnormal situation occurs, it should be dealt with in time.

2. When feeding the aluminum smelting furnace, some bulk materials should be placed on the bottom of the furnace to prevent collision and damage to the bottom of the furnace when placing the surface of the block materials.

3. In order to improve the smelting efficiency, enough charge should be placed in the shaft furnace, and the charge should be filled immediately throughout the smelting process to avoid wildfires.

Advance preparation before nozzle ignition.

1. Open all dampers of the device.

2. Start the centrifugal fan, open the nozzle baffle, purge the residual gas in the furnace, and close the nozzle baffle after a few minutes.

3. Start the oil pump, adjust the oil return pump and needle valve, the steam pressure in front of the nozzle is 0.1mpa.

4. When igniting, use the oil return pipe to inject enough oil, and put it in the proper position of the ignition hole in front of the nozzle after ignition.

5. When the fire detection alarm stops halfway, just click the "Alarm Reset" button to eliminate the alarm. Be sure to open the oven door before relighting. After confirming normal operation, close the furnace door to operate.

Send Inquiry to This Supplier

You May Also Like

-

Small Smelting Equipment, Industrial Furnace, Heating up Fast, 5 Tons of Aluminum Melting FurnaceCNY 65000 - 72000MOQ: 1 Set

-

Aluminum Smelting Equipment, Ingot Furnace, Industrial Metal Melting Casting Aluminum FurnaceUS$ 58000 - 63000MOQ: 1 Set

-

Fuel Oil Copper Melting Furnace, Non-ferrous Metal Melting,various Types of Fuel Copper Melting FurnaceUS$ 62000 - 64000MOQ: 1 Short Ton

-

Can be Customized a Variety of Specifications of Biomass Furnace Melting FurnaceCNY 62000 - 70000MOQ: 1 Short Ton

-

Nonferrous Metal Smelting 5 Tons of Large Fuel Gas Aluminum Melting FurnaceUS$ 62000 - 66000MOQ: 1 Short Ton

-

Large Double Shaft Shredder Multifunctional Metal CrusherCNY 65000 - 72000MOQ: 1 Set

-

Aluminum Alloy Melting Furnace Spot 500 kg Dump Crucible Melting FurnaceUS$ 1.2 - 2.3MOQ: 1 Set

-

Small Die Casting, Casting Aluminum Melting Furnace, Electromagnetic Induction Aluminum Melting FurnaceCNY 65000 - 72000MOQ: 1 Set

-

Continuous Heating Industrial Furnace, Tower Centralized Melting Insulation Furnace, Resistance Heat Treatment FurnaceUS$ 66000 - 71000MOQ: 1 Pound

-

Small Aluminium Smelting Furnace Waste Aluminium Smelting Equipment Industrial FurnaceCNY 65000 - 72000MOQ: 1 Set