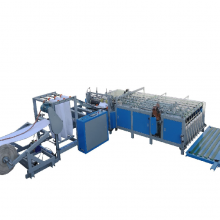

Lamination Machine for PP Woven Bags Woven Bag Printing Machine Woven Bag Cutting and Sewing Machine Integrated Machine

Machine introduction:

This machine is a medium-sized fully automatic equipment integrating automatic feeding, automatic deviation correction, fixed-length cutting, bottom sewing, printing, counting, and bag collection in one machine. It has a high degree of automation. It is easy to operate by one person and one machine. The machine adopts PLC control. Change the bag length, change the bag of different specifications, the adjustment is simple and quick, the system automatically calculates the proportional coefficient, and the printing of different lengths of sheets can be completed without changing the rollers and the front and back sides can be formed at one time. The slitting, slitting, and slitting can be converted mutually. One machine with multiple functions, high efficiency and energy saving.

Machine features:

◆Hot-cutting is mainly used for cutting uncoated bags. The resistance wire is not easy to fall off and the opening does not stick. Cold cutting is mainly used for cutting film-coated bags, using physical cutting, and the opening is flat. (Servo motor drives the cutter, cutting accurately, no printing accumulated error.)

◆This machine has multiple functions and integration, and can be used as a cutting and sewing machine, a cutting and printing machine, and a cutting and printing machine.

◆ Dual power cut bag portion, the smooth bags, cut neatly, and easy opening

◆ Stainless steel panel, beautiful and smooth running

◆ PLC computer centralized control, program upgrades can be performed regularly

◆ Single and double folding, uniform folding, adjustable thread length

◆Introducing the technical principles of foreign flexographic printing presses, through the fine-tuning device, the vertical/horizontal online (non-stop) quantitative positioning can be quickly registered at one time, which greatly reduces the repeated shutdown time for plate calibration and trial printing fabric losses, and improves production efficiency.

◆ Collect the bags neatly, chop them and push them, the number of bags can be adjusted, and the counting is accurate

◆According to customer needs, special specifications, can be processed and customized.

Machine parameters:

Model:RC-1300 Voltage: 380v

Motor power: 12kW

Production speed: 30-50 pieces/min Rubber sheet thickness:4-5mm

Folding width: 20-30mm Needle pitch: 8-15mm

Cloth roll maximum diameter: 1300mm Cutting width: 300-800mm

Cutting length: 400-1300mm Effective printing width: 900mm Weight: 2800kg

Size(L*W*H):11000×6000×1200mm

Send Inquiry to This Supplier

You May Also Like

-

Semi-automatic Two Cavity Bottle Making Machine Blow Molding EquipmentUS$ 1 - 100MOQ: 1 Set

-

Custom Design Semi-automatic Preform Pet Plastic Bottle Blowing Blow Molding Machine High SpeedUS$ 1 - 100MOQ: 1 Set

-

Semi Automatic PET Plastic Bottle 5 Gallon 20 Liter Blow Molding Machine PriceUS$ 1 - 100MOQ: 1 Set

-

Factory Price High Quality Automatic Fast Plastic PP HDPE Bottle Blowiing Jerrycan Extrusion Blow Molding MachineUS$ 1 - 100MOQ: 1 Set

-

High Speed Plastic Bottle Making 0.5L- 2L 6000BPH Automatic PET Bottle Blow Blowing Mold Molding Machine PricesUS$ 1 - 100MOQ: 1 Set

-

Fish Shape Mask Machine Facial Mask Machine KF94 Face Mask Machine AutomaticNegotiableMOQ: 1 Set

-

High Speed Automatic Surgical Cup Shape Respirator Medical Mask Machine ManufacturerNegotiableMOQ: 1 Set

-

N95 Mask Machine, Fully Automatic KN95 Mask Production Line Mask Making MachineNegotiableMOQ: 1 Set

-

Fully Automatical Disposable Face Surgical Mask Making Machine For Kn95 RespiratorNegotiableMOQ: 1 Set

-

3d Mask Machine Maker,Kn95 Mask Making Machine PriceNegotiableMOQ: 1 Set