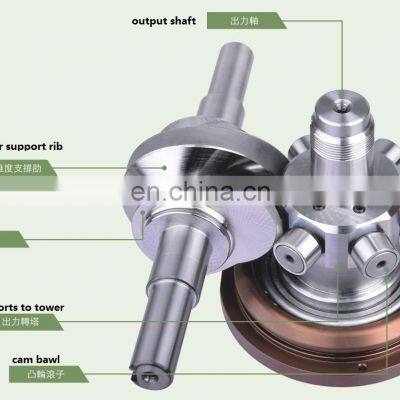

80DSF Series High Precision Cam Index

Disk diameter:300-800mm

Bearing weight:0-80KG

Mainly applied to:Automatic assembly and testing

Location and segmentation of equal parts:2,3,4,5,6,8,10,12,16,20,24,30,32,36,40,48

Driving angle:90°,120°,150°‘180°,210°,240°,270°,300°

Cam curve: deformation curve, deformation sine curve and deformation velocity curve.

Rotation direction of cam: left and right.

Standard accuracy:±30 seconds, customizable±15 seconds high precision.

Weight: 32 kg torque limiter (TL): 350 lubricant: 60#

Matching motor: 400W motor speed at 1400 or 1450.

Advantage:

One. Durability

1. cam processing technology is carburizing and grinding, the hardened layer is about 5mm.

2. surface spray paint is diaphragm type dry antirust oil.

3. the internal bearing is imported from Japan, NSK/NTN.

Two. Price concessions. In the same quality, our price is the most favorable.

Three. Large quantities of stock.

Parameter table:

All Allowable radial load of output shaft (C1): 330kgf

Max.repetitive torque on input shaft(C5): 25kgf-m

All Allowable axial load of output shaft (C2): 420 kgf

CD² on input shaft(Note1): 9*10-3kgf-m²

All Allowable torque of output shaft (Ts): Reference torque table

Indexing accuracy: ±30 Sec.

All Allowable radial load of intake shaft (C3): 350kgf

Weight:32 kg

Ma Max.repetitive bending force on input shaft (C4): 260 kgf

Note1:CD² on input shaft is value dwell ragne . Note2:Value of c1 to c5 are those obtained for safety factor=2.

Theroller is precisely fixed in the set position, so no locking elements are required.

High precision indexing self locking

The special desigh of cam roller can maintain high segmentation accuracy and torque, ensure the ability of heavy load, standard

segmentation accuracy in 30 seconds, can provide higher segmentation accuracy. The unique installation method makes the accuracy more accurate.

High speed and good torque

reduces the impact force produced by load or vibration,

Smooth running without noise

smoothly without vibration or noise.

Maintenance free life long

performance, long service life

performance.

projectors, Our production line are also including core components for optical metrology, such as VMM one basket controllers, lens, camera system, linear scales, VMM and CMM fixtures, illumination system etc...

dealers.Most of the Unimetro products are independent development, and our concept of design is stable and modularization, which

minimize the after sales service. This will help our partners to manage the products details and sales with minimize labor cost

and staff training cost.

3.Industry 3D print machines.

4.Fast Prototype from your Ideas.

5.Talented Engineering team Support within 24 hours feedback.

Send Inquiry to This Supplier

You May Also Like

-

High Quality Image Measuring Instrument /Laser Measuring Instrument PriceNegotiableMOQ: 1 Set

-

Full Automatic Vision Measuring System One-Button Measuring InstrumentNegotiableMOQ: 1 Set

-

High Accurate Bridge Type Three Coordinate Measuring Instrument/One-Key Image Measurement MachineNegotiableMOQ: 1 Set

-

Small Distance Measuring Instrument One-Button Measuring Instruments 2d Measuring SystemNegotiableMOQ: 1 Set

-

High Precision Speed Desktop Three-Coordinate Measuring Instrument For Automotive IndustryNegotiableMOQ: 1 Set

-

Automatic Three-Coordinate Measuring Instrument/Electronic Measuring Instruments For Mobile PhoneNegotiableMOQ: 1 Set

-

VMM Optical Measurement Machine Accessories PackageNegotiableMOQ: 1

-

Compact Type CNC VMMNegotiableMOQ: 1

-

Factory Direct Selling Quality Inspection Equipment 2D 3D CMM Video Measuring Equipment With RenishawNegotiableMOQ: 1

-

Economic Fully Automatic 2.5d Measurement Systems Optical Lens Machine for PCBNegotiableMOQ: 1