1. In order to prevent the welding corrosion caused by the heating of the flange cover, the welding current should not be too large, less than 20 or so than the carbon steel welding rod, arc arc should not be too long, fast cooling between layers, and narrow welding path is advisable.

2. The electrode should be kept dry when used. The titanium-Calcium type should be kept dry for 1 hour, and the low-A-hydrogen type should be kept dry for 200-250 hours, so as to prevent the electrode coating from sticking oil and other dirt, which may increase the carbon content of the welding seam and affect the quality of welding parts.

3. During the welding of flat welding flange pipe fitting, carbides are precipitated by repeated heating, which reduces the corrosion resistance and mechanical properties of the product.

4. The hardened American standard flange after welding of chromium flat welding flange is large and easy to crack. If the same type of chromium stainless steel electrode (G202, G207) welding, must be more than 300 preheating and welding after 700 or so slow cooling treatment. If the weldment cannot undergo post-weld heat treatment, the welding rod for flat welding flange (A107, A207) should be selected.

5, flat welding flange, in order to improve the corrosion resistance and weldability and add appropriate stability elements Ti, Nb, Mo, etc., weldability is better than chrome flat welding flange. When using the same type of chrome flat welding flange welding rod (G302, G307), should be more than 200 preheating and about 800 after welding temper treatment. If the weldment cannot be heat treated, the welding rod for flat welding flange (A107, A207) should be used.

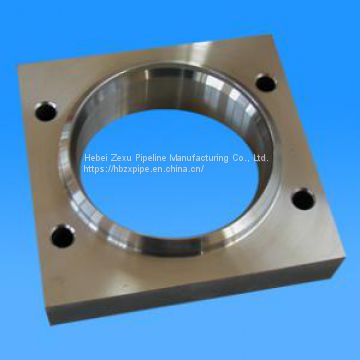

Main functions of flat welding flange:

1. Connect the pipes and maintain the sealing performance of the pipes;

2. Facilitate the replacement of a section of pipelines;

3. Easy to disassemble and check the pipeline;

4. Facilitate the closure of a section of pipeline.

Send Inquiry to This Supplier

You May Also Like

-

Specializing in the Production of Double - Phase Steel Flange Outstanding ManufacturersNegotiableMOQ: 2 Pieces

-

Flanged Short Tube Professional Manufacturers HereNegotiableMOQ: 2 Pieces

-

Professional Supplier of Socket Welding FlangeNegotiableMOQ: 2 Pieces

-

Professional Manufacturer of High-quality High-pressure Blind FlangesNegotiableMOQ: 2 Pieces

-

Specializing in the Production of Flat Welding Flange ManufacturersNegotiableMOQ: 2 Pieces

-

High-quality Production of Stainless Steel Flanging Ensures Customer SatisfactionNegotiableMOQ: 1 Piece

-

Forged Flange, A105 Hole Plate FlangeNegotiableMOQ: 1 Piece

-

Dual-phase Steel Flat Welding FlangeNegotiableMOQ: 1 Piece

-

Pressure Vessel Flange OEM Customized Precision Casting High Pressure FlangeNegotiableMOQ: 1 Piece

-

Long High Neck Flange High Quality OEM Precision Cast Steel Female Weld Long High Neck FlangeNegotiableMOQ: 1 Piece