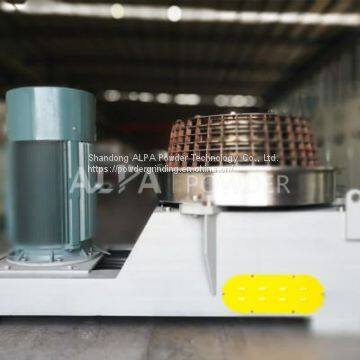

1-250um Powder Ultrafine Grinding Production Line Turbo Mill for Sale

1-250um Powder Ultrafine Grinding Production Line Turbo Mill for Sale

Especially suitable for the dispersion and reduction of agglomerated materials, such as: light calcium, kaolin, aluminum hydroxide, magnesium oxide, and ultrafine grinding of heat sensitive materials such as polyvinyl alcohol, PVC, PE, cellulose. Widely used in non-metallic minerals, chemicals, fuel, feed, food and other industries.

1.Available D50:1~250μm;

2.Conic rotor and stator are installed, product fineness and output can be controlled by adjusting the gap between the rotor and the stator;

3.The linear speed of grinding rotor can be up to 130m/s, high grinding effect;

4.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process;

5.PLC control system, easy operation;

6.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

Turbo Mill Working Principle

The material is uniformly fed into the grinding zone by feeding system and strongly impacted by the high-speed rotating grinding disc.

The grinding rotor is composed of a multi-layer grinding disc and a plurality of grinding blades, the material is subjected to various grinding forces such as shearing, collision, friction etc and finished grinding.

The qualified materials are collected into the collection zone with the ascending airflow, the coarse materials are returned to the grinding zone for secondary grinding.

Turbo Mill Technical Parameters

| Parameters/specifications | Rotor Diameter(mm) | Power (kw) | Rotate Speed(Max r/min) | Maximal Air Volume(m3/h) | Fineness(um) | Output(kg/h) |

| RTM-300H | 300 | 18.5~22 | 7550 | 1600 | 5~250 | 30~800 |

| RTM-500H | 500 | 45 | 4700 | 2400 | 5~250 | 80~2000 |

| RTM-750V | 750 | 55~75 | 3000 | 3600 | 5~250 | 100~3000 |

| RTM-1000V | 1000 | 90~110 | 2250 | 4800 | 5~250 | 200~4500 |

| RTM-1250V | 1250 | 110~132 | 1800 | 6000 | 5~250 | 300~6000 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

(abbreviation: ALPA / Equity Code: 171033)

In the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

Q: What service do you supply?

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:How can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. And we can provide free training for on-site workers.

Q:How to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

Send Inquiry to This Supplier

You May Also Like

-

0.5-16um Ultrafine Grinding Steam Jet Mill Milling SystemUS$ 9999 - 90000MOQ: 1 Set

-

1-16um Powder Milling Machine Steam Air Jet Mill PriceUS$ 9999 - 90000MOQ: 1 Set

-

R&D Ultrafine Grinding and Classifying Laboratory Jet Mill PriceUS$ 9999 - 90000MOQ: 1 Set

-

2-150um Powder Air Classifier Manufacturers in ChinaUS$ 9999 - 90000MOQ: 1 Set

-

5-150um Powder Vertical Air Classifier for SaleUS$ 9999 - 90000MOQ: 1 Set

-

3-45um Powder Vibratory Ball Mill Grinding and Classifying Production LineUS$ 9999 - 90000MOQ: 1 Set

-

Microns Powder Continuous Coating Grinder Pin Mill Powder Surface Modification ProcessUS$ 9999 - 90000MOQ: 1 Set

-

Vortex Mill Coating Production Line Powder Grinding and Coating SystemUS$ 9999 - 90000MOQ: 1 Set

-

Powder Surface Grinding and Modification Machine Continuous Coating ProcessUS$ 9999 - 90000MOQ: 1 Set

-

Batch Coating Process Powder Surface Modification Production LineUS$ 9999 - 90000MOQ: 1 Set