Precision Filtration of Powder Sintered Metal Porous Filter Material in Electrolytic Gas Production Industry

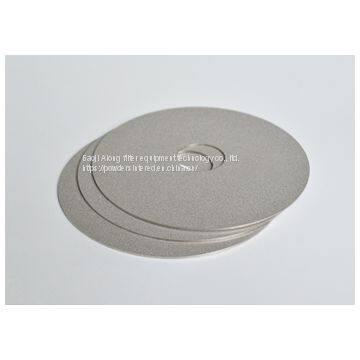

Titanium sintering porous materials

Titanium sintered porous material is a kind of porous material with high quality spherical and high purity titanium powder as raw material and it is made rigid by forming and sintering at high temperature.

1.Features of titanium sintered porous materials:

Titanium sintered porous materials have the characteristics of low density, high specific strength, good corrosion resistance, and good biocompatibility.

Material | Porosity | Penetrability | specific surface area | Working pressure | Operating temperature | Shape | |

Titanium powder | 0.5um-50um | 30-45% | 3-800M³/M²hKPa | 10-40cm²/cm³ | 2.0MPa | 300℃ | Round disc、sheet、tube、round bar、cap |

2.Specification of titanium sintered porous materials

(Diameter)Length | (Diameter)Width | Thickness | Customized | |

Sintered porous round discs | φ5-φ400mm | φ5-φ400mm | 1-20mm | Yes |

1-600mm | 5-400mm | 1-20mm | Yes | |

Sintered porous tubes | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

Sintered porous cartridge | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

3.Manufacture Standard GB/T 6887-2007 Sintered metal filter elements

4.Properties of titanium sintered porous materials

1) Pore diameter uniformity, pore stability, high separation efficiency.

2) High porosity, low filtration resistance, and high permeability.

3) Good chemical stability, acid, and alkali corrosion resistance, oxidation resistance.

4) Morphological stability, no particle shedding, comply with food hygiene and pharmaceutical GMP requirements.

5) Good mechanical properties, low differential pressure, large flow.

6) Strong anti-microbial ability, does not interact with microorganisms.

7) Online regeneration, easy cleaning, long service life.

8) Excellent biocompatibility can be widely used in biological, food, pharmaceutical, medical industry.

9) Excellent electromagnetic shielding performance.

10) Good damping and shock resistance.

5.Application of titanium sintered porous materials

Titanium sintered porous materials are mostly used for filtering materials、electrodes、heat transfer materials、catalyst carrier materials、noise canceling materials according to their physical and structural properties.

1) Decarburization filtration of pharmaceutical liquids.

2) Electrolytic gas industry precision filtration, gas distribution.

3) The medical industry makes biological implants.

4) Water treatment industry odor sterilization filtration and ozone aeration.

5) Clarification and filtration in food and beverage processing.

6) Prefiltration of reverse osmosis system for the electronics industry.

7) Terminal filtration of petroleum products in the petrochemical industry and filtration of carbonic alkali liquid in the chemical industry.

8) High-pressure air filtration in the aerospace industry.

9) Filtration and recovery of the precious metal catalysts in the fine chemical industry.

10) The electrode matrix of a fuel cell.

11) Catalyst carrier in gas and liquid catalytic reactions.

6. Titanium sintered porous materials are allowed to use in the environment

3% hydrochloric acid, 5% sulfuric acid, various concentrations of nitric acid (smoke nitric acid prohibited), chloroazotic acid, seawater, sodium hydroxide, carbonate, and chloride salts of the aqueous solution.

7.Precautions for the use of titanium sintered porous materials

1) During installation, disassembly, and clean avoid scratches, collisions, and falls on hard objects.

2) Install correctly to avoid reverse filtering.

3) Avoid instant pressurization when the filter element works. back blowing

4) When the filtration efficiency is less than 50%, the filter element should be cleaned in time.

5) When cleaning the filter element, first back blowing with pure gas, back blowing the pressure is 1.5 times the working pressure, each time for 3-5 seconds, and 4-6 times, then backwash with clean liquid for 3-5 minutes, repeat 2-3 times.

6) If the filter element is not good after online back blowing and backwashing, it should be removed and cleaned in time.

8.Method for cleaning titanium sintered porous materials

1) The decarbonization filter elements in the pharmaceutical and chemical industries are mainly back blowing and back washed, and the ultrasonic cleaning is the best.

2) The filter elements of the water industry are mainly rinsed with a 5% concentration of nitric acid.

3) According to the chemical properties of the filtered impurities, the filter elements of the original liquid shall be respectively soaked in pickling (5% nitric acid) or alkaline washing (3-5% sodium hydroxide) and then washed with ultrasonic cleaning.

Send Inquiry to This Supplier

You May Also Like

-

304,316L Stainless Steel Powder Sintered Porous Material Can be Backwashed for Multiple Use of the Filter PlateUS$ 2 - 5MOQ: 100 Pieces

-

Porous Gas Diffusion Electrode Materials, Production of Titanium Hydrogen Electrode Plate, Porous Titanium Electrode PlateUS$ 5 - 80MOQ: 100 Pieces

-

Microporous Stainless Steel Filter Plate, Metal Powder Sintered Filter PlateUS$ 5 - 80MOQ: 100 Pieces

-

Sintered Powder 5-micron Titanium Porous Filter Plate Porous Plate Electrode PlateUS$ 5 - 80MOQ: 100 Pieces

-

Sintered 316L Stainless Steel Metal Powder Porous Material Water Treatment Industry After Aeration FiltrationUS$ 2 - 5MOQ: 100 Pieces

-

Manufacturer Spot 5 Micron 20 Micron 30 Micron Sintered Metal Stainless Steel Porous MaterialUS$ 5 - 50MOQ: 100 Pieces

-

0.5mm Thick Spot Micron-grade Sintered Metal Titanium Porous MaterialUS$ 5 - 80MOQ: 100 Pieces

-

0.5mm Thick Spot Micron-grade Sintered Metal Titanium Porous MaterialUS$ 5 - 80MOQ: 100 Pieces

-

Custom Size Micron-level Filtration Precision Sintered Metal Stainless Steel Powder Porous MaterialUS$ 5 - 50MOQ: 100 Pieces

-

Spot Manufacturers of Micron - Grade Sintered Stainless Steel Metal Multi - Porous MaterialsUS$ 2 - 5MOQ: 100 Pieces