INTRODUCTION

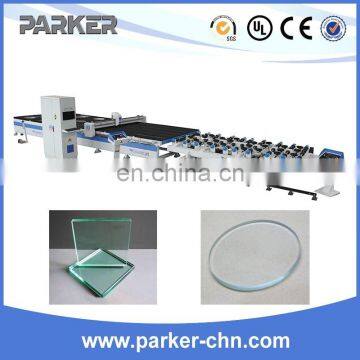

RGC - CNC glass cutting line is often used for cutting glass into any shape with high precision. It includes three sections covering automatic glass loading machine, automatic glass cutting machine and pneumatic glass breaking table. This automatic glass cutting production line adopts OPTIMA software, ADVANTECH industrial personal computer and OMRON servo motor. Controlled by the commercially PC, three machines of this CNC glass cutting line work together automatically in high speed and high precision. Besides, this automatic glass cutting production line can be widely used for architectural glass, furniture glass, auto glass, solar glass, and so on.

FEATURES

1. RGC CNC glass cutting line uses the imported servo motor, CNC controller and advanced control interface. Thus it is easy to handle and is of high cutting precision.

2. This automatic glass cutting production line adopts imported plastic table surface, bearing and rail to ensure more reliable and endurable performance.

3. Automatic CAD designed graphs and figures help the CNC glass cutting line to realize automatic cutting with all the cutting data fully computer controlled. The operator can edit the glass size for cutting into the computer. The computer can optimize the cutting size, give out the data for processing and drive the machine to cut glass sheet automatically.

4. This automatic glass cutting production line is equipped with double mechanical movement bridge system that can be automatically driven by motor.

5. CNC glass cutting line provides photoelectric scanning positioning and mechanism glass positioning modes. Unique shape of glass can be scanned by photoelectric scanning function and saved in CAD format.

6. Glass breaking machine and glass loading machine are optional for this automatic glass cutting production line.

7. Parker CNC glass cutting line can supply customized special specifications for customers.

TECHNIQUE PARAMETER

Glass Loading

This automatic glass cutting production line is equipped with double mechanical movement bridge system that can be automatically driven by motor.

Photoelectric Scanning Position

CNC glass cutting line provides photoelectric scanning positioning and mechanism glass positioning modes. Unique shape of glass can be scanned by photoelectric scanning function and saved in CAD format.

Automatic CAD designed graphs and figures

PARKER COMPANY

Founded in 2003, Parker Machinery Co., Ltd has developed an assembly line for door, window, curtain wall and insulating glass equipment. With over ten years' production experience, Parker has become a leading manufacturer of window door machinery in China. The operation of high precision, advancement and specialty ensure that we are able to supply high-quality window and door equipment for customers.

During the past few years, Parker has made great progress and has become well known and outstanding in domestic fairs for window door machinery. With advanced technological equipment, tremendous technical strength and reliable product quality, our window and door equipment has been well received by customers from Russian, Kazakhstan, Vietnam, Iran, etc. We have a perfect sales network and complete service system in China. We are also taking a leading role in setting branch companies abroad.

PARKER SERVICE

What you can do if my machines have problems?

a.We can send you free components to you if your machines are in guarantee time.

b.We can send our engineers to repair your machines.

Send Inquiry to This Supplier

You May Also Like

-

Different Shape Mirror Glass Cutting Machine From China FactoryUS$ 9,800 - 16,000MOQ: 1 Set

-

Hottest Automatic Foam Glass Production LineUS$ 90,000 - 260,000MOQ: 1 Set

-

Stainless Steel Laser Cutting Machine , Industrial Laser Cutter Equipment HECF3015IIWJUS$ 30000 - 200000MOQ: 1 Piece

-

Made in China Glass Laser Engraving EquipmentNegotiableMOQ: 1 Set

-

Sell SUDA Newest Cnc Engraver With 1.5kw Air Cooling SpindleNegotiableMOQ: 1 Set

-

Spare Parts for the Glass Tempering MachineUS$ 0.1 - 10MOQ: 1 Piece

-

Glass Grinding Machine UsedUS$ 75,000 - 950,000MOQ: 1 Set

-

Glass Washer And Dryer MachineUS$ 888 - 2,199MOQ: 1 Set

-

Laser Cutting Machine DW 1280US$ 3,300 - 6,500MOQ: 1 Set

-

Glass WasherUS$ 5,000 - 20,000MOQ: 1 Unit

Recommended Categories

Explore top categories and find suppliers for your specific needs-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.