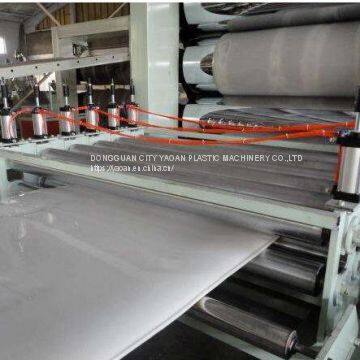

HDPE, PP Thick Sheet Extrusion Machine, Thick Board Production Line, Thickness Range: 2-15mm

Width of final product: 1500mm

Thickness range: 2-15mm

Extrusion Capacity: 250-350kg/hr (Max.)

Technical parameter:

| S.N | Description | Qty |

| 1 | AFSJ-150/30 Single- screw main extruder Gearbox: The body of the gearbox is made from cast steel. The teeth deal with grinding and peeling eventually, which provides damping, antifriction, low-noise, long using period etc. characteristics. The screw: Screw diameter: 150mm L/D: 30: 1 Screw structure: special Material: high quality nitrided steel-38CrMoAIA Nitration depth: 0.3-0.6mm, hardness≧ 740HV,fragility is 2 grades. The Barrel: Material: high quality nitrided steel-38CrMoAIA Nitration depth: 0.4-0.7mm, hardness≧ 940HV,fragility is 2 grades. Heating zones: 8 zones The electric heaters are made of cast aluminum. Each electric heater has a specially designed tunnel for heat radiation. The fans are featured with imported low lose and high effectiveness. Main motor: Power: 185 KW A.C motor ( ABB inverter control)

| 1 set |

| 2 | Fasten hydraulic pressure screen changer

| 1 set |

| 3 | T-die Effective width: 1700mm Material: adopt Japanese advanced heat proof alloy steel The flows are plated chrome. And the flow surface is polished until it like mirror. The outlets of the mould can be adjusted with the adjustable screws slightly.

| 1 set |

| 4 | Calender roll stack Structure: vertical Roll number: 3 Diameter of roll: 500mm Roll length: 1700mm Wall thickness of the roll: ≧25mm Roll surface treatment: treatment of mirror polishing The roll adopt Japanese alloy steel, and with hard chrome treatment, the hardness can reach RC60-65

| 1 set |

| 5 | 12 rollers cooling sizing unit Number of the steel rollers: 10 Roller length: 1700mm Roller surface treatment: plated chrome and half-mirror polishing

| 1 set |

| 6 | Air cooling stand Air cooling roller: 56 pcs

| 1 set |

| 7 | 4 rollers haul off unit Haul off rubber roller: 4 pcs Diameter of the roller: 240mm Length of the roller: 1700mm Surface treatment: coated erosion resistance, heat resistance and friction resistance rubber and polished. Clamping and open-close means: pneumatic

| 1 set |

| 8 | Trimming unit

| 1 set |

| 9 | Cutting machine & stacker Saw cutter: one set

| 1 set |

PLC Control system: one set Brand: SIEMENS Touch screen

| ||

Send Inquiry to This Supplier

You May Also Like

-

PET, PETG, PLA Sheet Extrusion Machine, No Yellow, Clear SheetNegotiableMOQ: 1 Set

-

Toe Puff Chemical Sheet Extrusion Machine , Toe Puff Sheet Laminating MachineNegotiableMOQ: 1 Set

-

TPU & Paper Coating Prodution LineNegotiableMOQ: 1 Set

-

TPU/TPR/TPV Rubber Band Extrusion MachineNegotiableMOQ: 1 Set

-

PE Foam Pipe, Tube, Solid Rod, Net Extrusion Production Line, CE Certificated, ISO 9001NegotiableMOQ: 1 Set

-

Plastic Window PVC Profile Extrusion Machine With High Output , Single Screw ExtrusionNegotiableMOQ: 1 Set

-

TPV, PP Wiper Blade Extrusion Poduction Line, Used To Make Windshield Flat Windscreen Wiper BladesNegotiableMOQ: 1 Set

-

PVC Hospital Handrail/ Corridor Handrail Extrusion Machine, PVC Wall Guard SystemNegotiableMOQ: 1 Set

-

Single Beam PP Spunbond Machine for Nonwoven Fabric , Nonwoven Fabric Making MachineryNegotiableMOQ: 1 Set

-

Automatic Plastic Vacuum Thermoforming Suit Case Luggage Forming MachineNegotiableMOQ: 1 Set