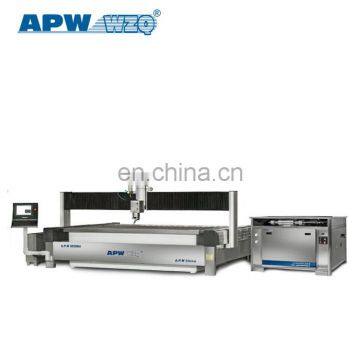

Italian CNC High Quality Diamond Orifice Water Jet for Metal Glass Marble With Double Intensifiers Pump

Water jet

Water jet cutting machine is made up of several critical key componnents, such as intensifier pump; cutting table with cutting head; CNC controller; auto abrasive delivery system.

A water jet cutting machine is made up of 4 key components, that is Intensifier pump; Cutting table; CNC controller; Auto abrasive feeder

Dual-Core water jet Debut

The new APW "Dual-Core" pump of water jet cutting machine is equipped with dual intensifiers imported from the USA. The two intensifiers are able to work by alternative way. It significantly reduces the maintenance time, and expands the life span of the pump.

Imported components

We adopt the imported component of water jet cutting machine like Rexroth hydraulic pump; USA intensifier; Siemens motor;Omron PLC; Yaskawa servo drive; Yuken direction control valves etc. The whole parts of Intensifier are assembled in USA (not just some parts), most of the smaller parts are also imported from USA to ensure its good stability during cutting, durability and long working service life.

Celebrating 10 years Alibaba Gold Membership and 15 years professional water jet manufacturing, we have carried out two kinds of promotions.

All-Powerful Science & Technology Stock Co.,Ltd, a Sino-US joint venture, which was established at 2001 and located in the Export Processing Zone of Liaoning Provence. APW is the largest new high-tech enterprise integrated the research and development of ultra-high pressure water jet cutting machine, and an important base for developing high-end ultra-high pressure water jet cutting machine industry of China.

Our mission is to help our customers solve their manufacturing challenges and achieve their highest level of productivity, precision and accuracy.

CNC water jet cutting machine will be packed in standard packaging, which suitable for long distance ocean transportation and well protected against damage, moisture, shock, rust and handling.

CNC water jet cutting machine have got the consistant high praise from the customer at home and abroad during the 15 years development, there are many successful stories related to APW water jet cutting machine, we are looking forward to seeing you in our picture wall.

1. What are the benefits of purchasing a water jet comparing CNC plasma or a laser ?

Versatility

Abrasive water jet can cut almost anything – from metal to stone to glass to composites to ceramic.

Laser and plasma cut with heat, and so can only cut materials that have the right thermal properties. Metal is almost always the target material in industry for these heat-based processes. And mild steel is almost always the metal that is cut by them. In addition, plasma can only cut things that are electrically conductive. To optimize laser and plasma cutting, change to gasses is required. No change to water jet parameters, except speed, is usually required for any material.

Thickness

water jet can cut very thin and up to 150mm (sometimes more) of any metal, glass, stone, composite, etc.

Laser cuts very thin and up to 20mm.

Plasma cuts from about 25mm up to 30mm.

Edge finish

Nothing cut by a plasma or laser will be as high of quality of an edge as a water jet. We leave behind a smooth edge. No heat affected zones or mechanical stresses are introduced. The plasma and laser cut with heat (we cut with supersonic erosion). Plasma and laser therefore will leave behind a heat affected zones, mechanical stresses, and especially with plasma, dross 'drips' on the edge.

Please contact us for more information of our water jet cutting machine.

2. What kind of material does your machine can cut?

There are plenty materials our water jet machine can cut , such as metal stone glass foam plastic rubber, ect.

4-axis was professionally designed for mable pattern and medallion.

5-axis was professionally designed for 3D materials.

3. What's your machine's max.cutting thickness?

The max.cutting thickness of our water jet depends on the materials you cut .

Generally speaking, the thickness of our water jet cutting machine can be up to 150mm, virtually Z constraint is the only limit to thickness.

4.What kinds of payment do you accept?

It depends on the region.

More information about APW water jet cutting machine price pls contact us .

Send Inquiry to This Supplier

You May Also Like

-

Different Shape Mirror Glass Cutting Machine From China FactoryUS$ 9,800 - 16,000MOQ: 1 Set

-

Hottest Automatic Foam Glass Production LineUS$ 90,000 - 260,000MOQ: 1 Set

-

Stainless Steel Laser Cutting Machine , Industrial Laser Cutter Equipment HECF3015IIWJUS$ 30000 - 200000MOQ: 1 Piece

-

Made in China Glass Laser Engraving EquipmentNegotiableMOQ: 1 Set

-

Sell SUDA Newest Cnc Engraver With 1.5kw Air Cooling SpindleNegotiableMOQ: 1 Set

-

Spare Parts for the Glass Tempering MachineUS$ 0.1 - 10MOQ: 1 Piece

-

Glass Grinding Machine UsedUS$ 75,000 - 950,000MOQ: 1 Set

-

Glass Washer And Dryer MachineUS$ 888 - 2,199MOQ: 1 Set

-

Laser Cutting Machine DW 1280US$ 3,300 - 6,500MOQ: 1 Set

-

Glass WasherUS$ 5,000 - 20,000MOQ: 1 Unit