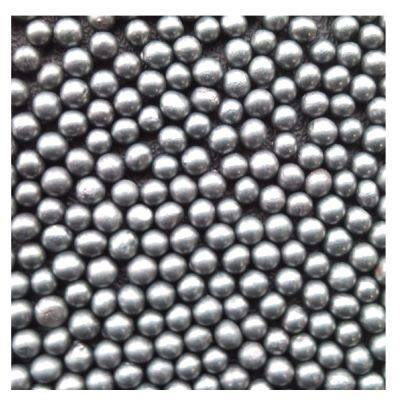

Blast Media Steel Shot for Shot Blast

Remark: The final prices should be subject to the negotiated prices.

Steel Shots & Steel Grits are made of tempered martensite, with moderate hardness, excellent elasticity, wear-resistant, give less dust, longer recycle life, low cost, extensively used for shot peening to give residual stress in the surface layer of components for fatigue life enhancement and suppression of stress corrosion cracking and descaling and cleaning up surfaces of castings, steel parts and mechanical work-pieces prior coating. They are also extremely ideal materials for cutting granite.

Applications | ||

Steel Shots | Steel Grits | Applications |

SS-2.5 22-2.0 | SG-2.5 SG-2.0 | Removing sand, descaling,for large-size of castings, forging, heat-treated workpieces, steel structure. |

SS-1.7 SS-1.4 | SG-1.7 SG-1.4 SG-1.2 | Removing sand, descaling,intensification for large-size and middle-size of castings, forging, heat-treated workpieces, steel plate, steel structure, |

SS-1.2 SS-1.0 | SG-1.0 SG-0.7 | Removing sand, descaling,intensification for small-size and middle-size of castings, forging, heat-treated workpieces, aluminium-copper alloy castings, steel plate, trip steel, steel pipes. |

SS-0.8 SS-0.6 | SG-1.0 SG-0.7 | Removing sand, descaling,intensification for small-size of castings, forging, heat-treated workpieces, aluminium-copper alloy castings, steel plate, trip steel, steel pipes, springs and chains. Grinding processing |

SS-0.5 SS-0.3 | SG-0.4 SG-0.3 | Removing sand, rust, descalling, intensification, improving roughness and adhesiveness for small-size of alloy castings, thin steel plate, trip steel, stainless steel , springs. |

Chemical-Physical Characteristics | ||||

Item | Steel Shots | Steel Grits | ||

GP | GL | GH | ||

Hardness ±3HRC | 40-50 | 42-45 | 56-60 | 63-65 |

Specify gravity | 7.2g/cm3 | |||

Metallographic Struture | Even Tempered Martensite or Troostite | |||

Chemical composition,% | C: 0.85% – 1.20%; Mn: 0.60% - 1.20%; Si: 0.40 %– 1.20%; | |||

| SCREEN NUMBER | Size | SAE J-444 SHOT SCREENING SPECIFICATIONS | ||||||||||

| (mm) | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S070 | |

| 6 | 3.35 | |||||||||||

| 7 | 2.80 | 0 | ||||||||||

| 8 | 2.36 | 0 | ||||||||||

| 10 | 2.0 | ≥85% | 0 | 0 | ||||||||

| 12 | 1.70 | ≥97% | ≥85% | ≤5% | 0 | |||||||

| 14 | 1.40 | ≥97% | ≥85% | ≤5% | 0 | |||||||

| 16 | 1.18 | ≥97% | ≥85% | ≤5% | 0 | |||||||

| 18 | 1.00 | ≥96% | ≥85% | ≤5% | 0 | |||||||

| 20 | 0.850 | ≥96% | ≥85% | ≤10% | 0 | |||||||

| 25 | 0.710 | ≥96% | ≥85% | ≤10% | ||||||||

| 30 | 0.600 | ≥96% | ≥85% | 0 | ||||||||

| 35 | 0.500 | ≥96% | ≤10% | |||||||||

| 40 | 0.425 | ≥85% | 0 | |||||||||

| 45 | 0.355 | ≥97% | ≤10% | |||||||||

| 50 | 0.300 | ≥80% | ||||||||||

| 80 | 0.180 | ≥90% | ≥80% | |||||||||

| 120 | 0.125 | ≥90% | ||||||||||

| 200 | 0.075 | |||||||||||

| SS-2.5 | SS-2.0 | SS-1.7 | SS-1.4 | SS-1.2 | SS-1.0 | SS-0.8 | SS-0.6 | SS-0.5 | SS-0.3 | SS-0.2 | ||

Remark: The final prices should be subject to the negotiated prices.

Send Inquiry to This Supplier

You May Also Like

-

Sand Blasting Media Glass Beads Micron Spherical for CleaningUS$ 0.3MOQ: 25 Kilograms

-

Abrasive Melamine Formaldehyde Urea Formaldehyde Plastic Blast Media for Soft Sand Blasting MF UF NRUS$ 2MOQ: 25 Kilograms

-

Blast Media Almandine Garnet Sand Blast Water Jet CuttingUS$ 0.2MOQ: 25 Kilograms

-

Abrasive Blast Media White Aluminium Oxide for Sand Blasting Blast Media White Aluminium OxideUS$ 1MOQ: 1000 Metric Tons

-

Abrasive Blast Media Brown Aluminum Oxide for Sand BlastingUS$ 1MOQ: 1000 Kilograms

-

Zirblast Ceramic Beads for Shot Blasting Cleaning Zirshot Abrasive Blast MediaUS$ 3MOQ: 25 Kilograms

-

Stone Shot Blasting Machine for Stone Aging AntiqueUS$ 14000MOQ: 1 Set

-

Abrasive Recycling Machine for Blast Cleaning SiteUS$ 5000MOQ: 1 Set

-

Rotary Drum Shot Blasting Machine for Surface CleaningUS$ 2000 - 20000MOQ: 1 Set

-

Belt Conveyer Blast Machines Blast Cabinet Automatic Blast Machine In-line Feed Belt ConveyorUS$ 3000MOQ: 1 Set