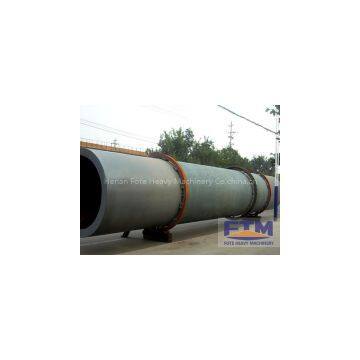

Brief Introduction of Desulfurization Gypsum Dryer:

Desulfurization gypsum dryer is also known as gypsum dryer, and it is indispensable drying equipment in building material industry. At present, this equipment is mainly used for drying materials in mine, chemical, building materials and other industries. With the growing awareness of environmental protection, the government has tighter and tighter control on the emission of the sulfur dioxide in the coal-fired flue gas by power plants, so that desulfurization is imperative. Desulfurization gypsum has some differences from natural gypsum, for example, desulfurization gypsum has high purity, big free water and fine granularity. The size distribution is even and the gradation is bad and the water consumption for standard thickness is high. It is noteworthy that the source of desulfurization gypsum and natural gypsum is different. In addition, the main impurities of the Desulfurization gypsum are the unreacted calcium carbonate and the fineness of the processing limestone will influence the quality of the desulfurization gypsum.

Working Principle of Fote Desulfurization Gypsum Dryer:

Desulfurization gypsum enters the revolving canister of dryer through feeding device, and then is lifted up and scattered down by the lifting plate to increase its contact area with the hot air. Because the effects of the dryer's own angle, spiral lifting plate and the material's gravity, it slowly falling down, finally achieve the purpose of drying, and is discharged by the discharge mouth at the end of dryer.

Main Features of Desulfurization Gypsum Dryer:

1. Chemical gypsum can be directly made β-semi-hydrated gypsum powder.

2. It ensures the making duration and temperature requirement of the calcination of gypsum powder from the technology.

3. The pan machine has reasonable design in air outlet, so that there is no dust pollution in the running process.

4. When the materials are fed in intervals, the machine can be stopped, and only three minutes will be needed to resume to normal operation.

5. It is equipped with gas stove or furnace in fluid bed for heat supply, and tail gas and waste heat can be recycled for boiling water or heating the air.

6. The design of dryer air outlet is reasonable, and it operates without dust pollution.

| Model(mm) | Gradient(%) | Rotating speed(r/min) | Intake air temperature(℃) | Main motor power(kw) | Production capacity(t/h) | Weight(t) |

| Φ1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Φ1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Φ1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Φ2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Φ2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Φ2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| Φ2400×20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

Desulfurization Gypsum Dryer Manufacturer:

Fote Machinery is a professional dryer machine manufacturer, and we have various kinds of dryer machines for sale, which has reasonable structure, top quality and thoughtful services. If you want to know more information about the dryer machine price, please leave us a message below or send emails to us, we will answer you as soon as possible!

Send Inquiry to This Supplier

You May Also Like

-

All Kinds of Mining Machinery and Wide-Body Mining Trucks, Mining Dump Truck, ExcavatorNegotiableMOQ: 1 Set

-

Gravity Separation 6-S Shaking TableNegotiableMOQ: 1 Set

-

Compact Mini Excavator 0.8T Operating Weight for Efficient Digging WorkNegotiableMOQ: 1 Set

-

ISO9001 Certificated Bimetal Wear Resistant Clad Plate Bucket Excavator WheelUS$ 160 - 160MOQ: 1 Piece

-

Track Mini Excavator for Sale 2 Ton 2.5 3 Ton 5 Ton Small Rubber China Cheap Price 0.6 Ton 0.8 Ton 1 Ton 1.5 Ton 1.7 Ton 175mmNegotiableMOQ: 1

-

Essential Vibrating Bowl Feeder/vibrating FeederUS$ 9,700 - 10,000MOQ: 1 Set

-

Oil&Gas Drilling Mud Desander and DesilterNegotiableMOQ: 1 Set

-

Ceramic Particle Production Line With ISO9001:2008 CertificateUS$ 5,000 - 50,000MOQ: 1 Set

-

Hot Sell High Frequency GTS Series Drum ScreenUS$ 500 - 40,000MOQ: 1 Set

-

Hot Sale and Newly Vibrating Table Concrete for PaverUS$ 500 - 6,000MOQ: 1 Set