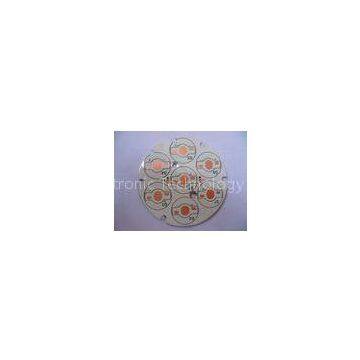

Single Layer High Power Metal Core PCB LED COB MCPCB for Street Lights

Certification:ISO

Single Layer High Power Metal Core PCB LED COB MCPCB for Street Lights

Product Name: | LED COB MCPCB | Material: | Metal Core |

Layer Count | Single Layer | Board Thickness: | 1.5mm |

Power | 1 - 100 W | Input voltage | Immersion Gold |

Original | China PCB Manufacturer | Applications: | Street Lights |

Descriptions:

COB MCPCB (known as \"Chip-On-Board\" metal core PCB) is a type of MCPCB used in thermoelectric separation application. By using COB MCPCB, the micro-chip (also known as “die\") directly touches the metal core where the heat dissipate and electrically interconnect the trace of circuit board (wire-bonding) so that power supply can be provided.

In normal MCPCB, there\'s a dielectric layer between trace copper and metal core. And the thermal conductivity is limited with the dielectric layers, the value is 1~3 100W/m.K. But using COB MCPCB, there\'s no such dielectric layer but chip (die) direct touch the metal core, so thermal conductivity value of COB MCPCB will be almost the same with metal core material itself. The normal material of metal core is aluminum, and the thermal conductibility of COB MCPCB could reach more than 200W/m.K.

COB process consists of three main categories to perform when manufacturing

Metal Core PCB applications

Thermal Clad PCB Material

Metal Core PCB Specifications

Metal Core PCB Benefits

Thermal Clad Metal Core PCB fabrication contact us for more details.

Workshop View:

Send Inquiry to This Supplier

You May Also Like

-

Actived Charcoal Filter CylinderNegotiableMOQ: 20 Sets

-

Reusable Eco Friendly Bamboo Fiber Cotton Cosmetic Remover Double Layer PadNegotiableMOQ: 20000 Pieces

-

5L Laser IPL Medical Cooling Ultrasonic Medical Transparent Ultrasound Scan ECG Gel Ultrasound Transmission Gel Ultrasound Coupling AgentUS$ 0.1 - 1.1MOQ: 1 Carton

-

Vinyl GlovesUS$ 1.4 - 1.8MOQ: 1000 Boxes

-

Human Hair Extension,hair Weft,wig,hair PieceNegotiableMOQ: 30 Kilograms

-

Argentina Home & Office FurnitureNegotiableMOQ: 1 Kilogram

-

Offer Legal Advicing Service (Poland)NegotiableMOQ: 1 Kilogram

-

Sell Business SuitNegotiableMOQ: 1 Kilogram

-

Precision|MIM Process Machining - Flight Instrument PartsNegotiableMOQ: 1 Kilogram

-

4 Bow Stainless Steel Bimini TopNegotiableMOQ: 1