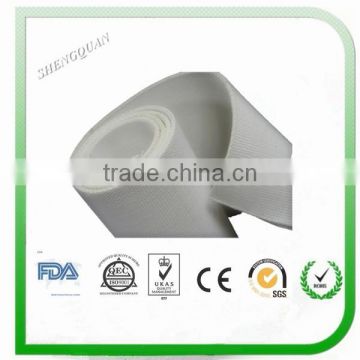

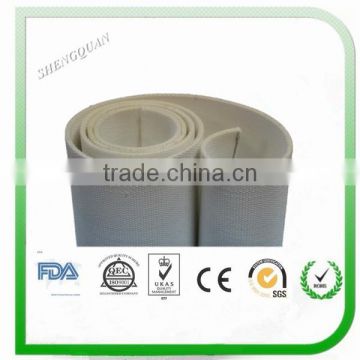

Cement Airslide Fabric Converyor Belt 100% Polyester(For Aeration of Bulk Powder)

Air Slide Pneumatic Conveyor Systems consist of Air feed unit like blower, metallic bellow or compressor which are the sources of air stream supply; product feed pneumatic conveyor comprising two pressurized chambers or channels, positioned one upon another at their open trough ends with the Air Slide Fabric separating them. The pressurized air is fed into the bottom chamber and permeates through the fabric entering the top chamber where it picks up the product being feed into it at the upper gradient end transports it to the collection point at the lower gradient end.

There is an air separation arrangement at collection point or filter unit, which separates the solid powder product stream from the air stream. This may be a cyclone separator, bag house filter or precipitator and material product is collected in bin, silo, or hopper either for storage or mixing or blending or if in a finished product stage to the packing plant.

smooth surface

abrasion resistance

stable air permeability

super air permeability

easy assemble

long service life

Mainly used in powdery material air/pneumatic conveying, in cement industry used for Air conveying chute.

Send Inquiry to This Supplier

You May Also Like

-

Conveyor650 Cable Conveyor Machine With 3400N Max TensionUS$ 1300 - 1500MOQ: 1 Combo

-

Flexible Grain Suction Screw Conveyor for Farm UseUS$ 490 - 1,500MOQ: 1 Set

-

Used for Oilfield Drilling Waste Screw Auger ConveyorNegotiableMOQ: 1 Set

-

Portable Belt Conveyor Machine PriceUS$ 500 - 5,000MOQ: 1 Set

-

Shanghai Low Cost Flexible Tube and Auger Spring Screw Conveyor MachineUS$ 4,400 - 4,400MOQ: 1 Set

-

Needled Industrial 5mm Thick 100% Wool Felt for WholesaleUS$ 5 - 20MOQ: 50 Meters

-

24V LiFePO4 Battery for AGV 60Ah, 48V100AhNegotiableMOQ: 1 Piece

-

Reliable Quality v Belt Conveyor With Iron Remover RCYB-8US$ 2,000 - 4,000MOQ: 1 Set

-

Low Investment Car Production Line for SaleUS$ 1,000 - 1,000,000MOQ: 1 Set

-

Used Rubber Conveyor Belt PriceUS$ 100 - 500MOQ: 1 Set