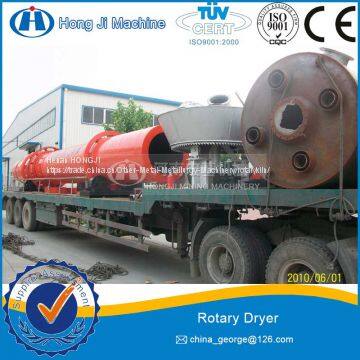

hina Supplier Hot Sell High Quality Coal Gangue Slurry PowderRotary Dryer

Detailed Description of Coal Gangue Slurry Powder Rotary Dryer

Coal slime rotary dryer is applied in such materials as coal slurry, mud, filter gypsum, muddy,high-moisture swell soil, electroplate mud and more with the advantage of big capacity,low energy cost and high efficiency.

Overview of Coal Gangue Slurry Powder Rotary Dryer

As a kind of highly efficient, stable and reliable heating drying equipment, the performance of Coal Slime rotary dryer is better than tube bundle rotary dryer and blade rotary dryer, which is designed by DeRui Group

for the drying of dry materials of high mositure or strong stickiness.

As a professional rotary kilndryer manufacturer,we are capable of offering kiln dryers which have the character of being easy to operate and durable in use. It is widely used for different materials with a sawdust dryer capacity of 200-5000kg per hour. In addition,we are also a professional sawdust dryer supplier, and the sawdust dryer manufactured in our factory can be widely used in drying slag, sand, coal and most of high moisture material. The coconut dryer drying time is 40-80 mins.

The coal slime dryer consists of heating part, breaking part, belt feeder, feeding part, rotary drum, belt discharging part, fan, unloading part and distribution cabinet. The slime dryer is mainly used for dealing with following material:

1. Coal industry : including slime, coal , flotation coal concrete and mixed coal

2. Construction industry: including blast furnace slag, clay, limestone, sand and quartz

3. Ore dressing industry: including all kinds of metal ore, slag and tailings.

4. Chemical industry: including non-heat-sensitive materials.

Features of Coal Gangue Slurry Powder Rotary Dryer

Large capacity,low fuel consumption,low drying costs;

High thermal efficiency: It adopts downstream drying. Both the heated gas and wet materials enter the coal slime dryer from the same side, the high-temperature gas create strong evaporation and outlet temperature is comparatively low.

Operating parameters can be changed depending on the material properties, so that the material in the dryer cylinder body is capable of forming a stable full cut fabric curtain to get full heat exchange;

New feeding and discharging devices to solve the problem of feed clogging, not continuous, uniform and

returning materials of the slime drum dryer reducing the load of dust removal system;

New internal structure and strengthen the function of cleaning and thermal conductivity of the dispersed material, avoid material sticking on the cylinder wall.

It achieves " zero thrust “ of this coal slime dryer, which greatly reducing wear of roller block, smooth and reliable operation;

Adopt " self-aligning roller-type device ", make roller and rolling ring linear touch forever, thus greatly reducing the wear and power loss;

The user can control the material particle size and moisture according to requirements, the finished slime mositure is less than 8%, and particle size can be controlled in 8mm.

Working Principle of Coal Gangue Slurry Powder Rotary Dryer

Coal is a kind of fuel, and coal slime can also be burned at high temperature. DeRui has developed H series rotary coal slime dryer, and 4 stage drying process are adopted for it. In the first stage, coal slime shall be fed and impacted at the temperature of 600 Celsius Degree, moving most of the moisture; in the 2nd stage,coal slime shall be scattered repeatedly to avoid sticking on the wall at the temperature of 450 Celsius Degree, the coal slime will not be coked during this stage; in the 3rd stage, the coal slime shall be repeatedly lift up, broken and fell down by the breaking device at the temperature of 300-400 Celsius Degree; in the 4th stage, hot air drainage area with negative pressure and high temperature shall be formed by the induced draft fan at the temperature of 150-250 Celsius Degree. The temperature at discharging port is 60-80 Celsius Degree. The calorific value will be increased to 1400Kcal with water content of 10% after drying procee.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Carbon Fiber Rotary Dryer Sourh AfricaEUR 1 - 1MOQ: 1 Ton

-

Rotary Dryer for CoalEUR 1 - 1MOQ: 1 Ton

-

Sand Drying Equipment for SaleEUR 1 - 1MOQ: 1 Ton

-

Where to Buy Silica SandEUR 1 - 1MOQ: 1 Ton

-

Dried SandEUR 1 - 1MOQ: 1 Ton

-

Rotary Drying MachineEUR 1 - 1MOQ: 1 Ton

-

Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

iq oq dq for Rotary Vacuum DryerEUR 1 - 1MOQ: 1 Ton

-

Silica and Quartz Sand Rotary Dryers for Drying Sand With Direct Factory Price Hot in America and AustraliaEUR 1 - 1MOQ: 1 Ton

-

Silica Sand Rotary Drum Dryer / Drying Machine/tuEUR 1 - 1MOQ: 1 Ton