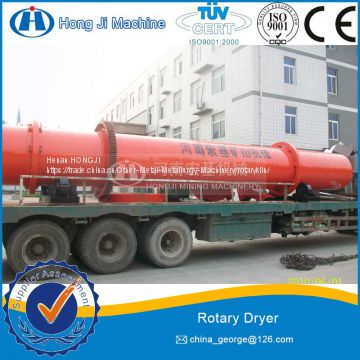

rotary dryer features:

1.For drying mineral ore,sand,coal

2.full technical support and low cost

3.fast delivery

4.ISO9001

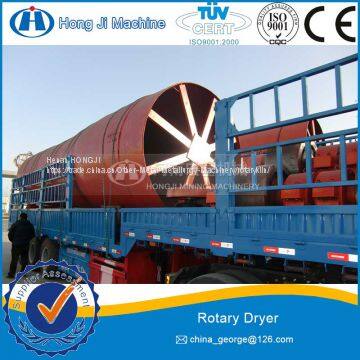

Structure of rotary dryer machine:

The drying machine is mainly used for the drying of the particulate materials with certain humidity and granularity. The rotary dryer machine has the wide application range in the building materials, metallurgy, chemical and cement industries to dry the slag, limestone, coal powder, slag, clay and other materials as well as other small particles that can stand the high temperature and soot-stained materials. The rotary dryer machine is mainly comprised of rotary body, lifting blade, transmission device, supporting device and seals and other components.

Features rotary dryer machine:

1. Compact structure, reasonable layout and simple structure.

2. Reliable operation, low energy consumption, high thermal efficiency of rotary dryer machine.

3. Easy to automatic control, reduce operating personnel,save the labor resources.

4. Small foundamental investment reduces the one-off investment.

Production process of rotary dryer machine:

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Dried SandEUR 1 - 1MOQ: 1 Ton

-

Rotary Drying MachineEUR 1 - 1MOQ: 1 Ton

-

Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

iq oq dq for Rotary Vacuum DryerEUR 1 - 1MOQ: 1 Ton

-

Silica and Quartz Sand Rotary Dryers for Drying Sand With Direct Factory Price Hot in America and AustraliaEUR 1 - 1MOQ: 1 Ton

-

Silica Sand Rotary Drum Dryer / Drying Machine/tuEUR 1 - 1MOQ: 1 Ton

-

Widely Used High Drying Rate Silica Sand Rotary DrierEUR 1 - 1MOQ: 1 Ton

-

Silica Sand Dryer With ISO,CE Quality ApprovedEUR 1 - 1MOQ: 1 Ton

-

High Efficiency of Steam Tube Rotary Dryer For SaleEUR 1 - 1MOQ: 1 Ton

-

Hot Selling Mineral Powder Rotary Dryer With CE & ISOEUR 1 - 1MOQ: 1 Ton