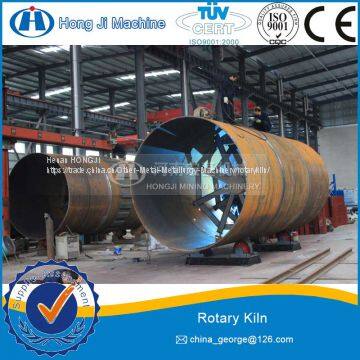

Structure of cement making machine Cement Rotary Kiln

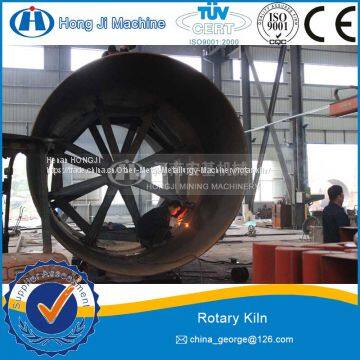

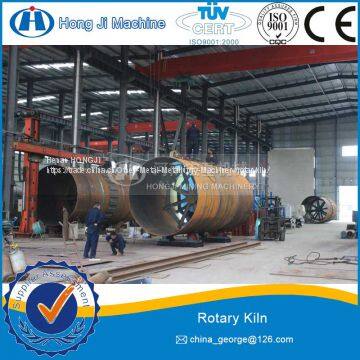

cement making machine Cement rotary kiln is mainly composed of cylinder, sealed cap supporting roller, small and big gearwheels and driving parts(including motor and reducer). The accessories used in the calcinating production line include preheater, cooler, fan and etc..

Application of cement making machine Cement Rotary Kiln

1. In building material industry, rotary kiln can also calcinate clay, limestone and slag besides cement clinker.

2. In ore beneficiation process, rotary kiln can enhance the magnetism of iron ore through magnetization roasting to facilitate the separation.

3. In the chemical industry, rotary kiln is used to calcinate soda, phosphate fertilizer, barium sulfide and etc..

Advantages of cement making machine Cement Rotary Kiln

1. low energy consumption or energy saving way of calcination

2. reasonable design so that the waste heat can be most effectively reused

3. cement rotary kiln is equipped with dust catcher to filter waste gas and dust to meet the standard of waste gas emission.

4. the fans with realiable performance to guarantee the calcinating condition

5. high automation level

Working Principle of cement macking machine Cement Rotary Kiln

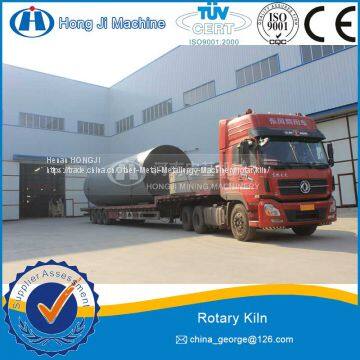

cement making machine Cemen rotary kiln is installed with slope, generally 4-5%. The motor drives the gearwheels to rotate. The materials to be calcinated are put into the feeding port, which is on the higher side. While the cement rotary kiln is rotating, materials go through the cylinder of cement rotary kiln. The cylinder can be divided into four areas: feeding area, preheating area, main calcinating area and cooling area. After going through these four areas, materials are discharged. Generally the discharging port of cement rotary kiln is connected with cooler so that the discharged materials can go to the cooler to lower the temperature.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Lime KilnEUR 1 - 1MOQ: 1 Ton

-

Rotary Kiln BrochuresEUR 1 - 1MOQ: 1 Ton

-

Liime KilnEUR 1 - 1MOQ: 1 Ton

-

Rotary Kiln Sampah Domestik GresikEUR 1 - 1MOQ: 1 Ton

-

Cement Calciner Kiln PriceEUR 1 - 1MOQ: 1 Ton

-

Ducting Tod di Kiln CementEUR 1 - 1MOQ: 1 Ton

-

Pengertian Tungku Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Rotary Drum DryerEUR 1 - 1MOQ: 1 Ton

-

Perhitungan Beban Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Coal Drying PolandEUR 1 - 1MOQ: 1 Ton