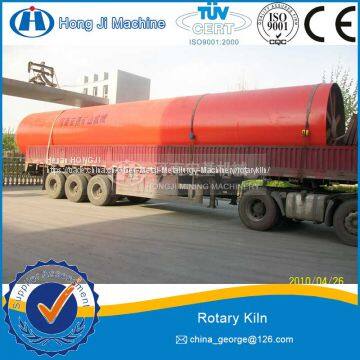

Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials

produced using rotary kilns include:cement, lime, refractories,metakaolin,titanium dioxide,alumina,vermiculite,iron ore pellets, zinc

oxide,etc.

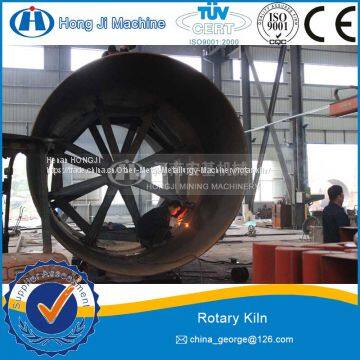

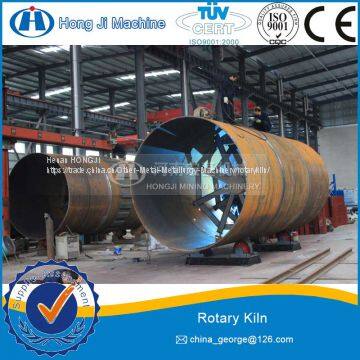

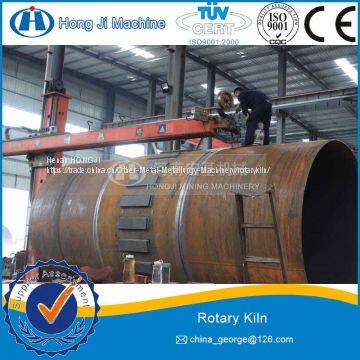

Working principle of EAF dust rotary kiln:

kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed

s fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may

undergo a certain amount of stirring and mixing.

EAF dust rotary kiln working process:

The kiln feed material, comprised of zinc ‘waste,’ fluxes, and reductant (coke), is typically pelletized before addition to the kiln. First, however, EAF dust is pre-conditioned via blending with water. This helps to reduce dust during processing and also

prepares the material for pellet formation on the disc pelletizer.

Once pre-conditioned, the material is fed onto the disc pelletizer. Here, pellets are formed through the rotation of the disc in the presence of a binding agent (in this case water) in a process referred to as coalescence. Ideal pellet size range for the EAF dust

recycling process is typically around 1/6” to ¼”.

Once pellets have reached the desired size, they exit the disc pelletizer and are fed to the rotary kiln. The pellets are heated to a specified temperature, where the carbon reduces the zinc oxide to metallic zinc. This metallic zinc will vaporize, and the metal

vapor is then oxidized above the kiln bed to reform zinc oxide mist, which is then carried out of the kiln to the dust collection system. The material is then cooled, which is commonly carried out in an industrial cooling system such as an indirect rotary cooler, and then collected for storage or transport.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Rotary Drum DryerEUR 1 - 1MOQ: 1 Ton

-

Perhitungan Beban Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Coal Drying PolandEUR 1 - 1MOQ: 1 Ton

-

Pemanas Rotary Dryer Dengan Bahan ArangEUR 1 - 1MOQ: 1 Ton

-

Typical Cost of Drying CoalEUR 1 - 1MOQ: 1 Ton

-

Dryer Silica SandEUR 1 - 1MOQ: 1 Ton

-

Prinsip Kerja Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Rotary Dryer DesignEUR 1 - 1MOQ: 1 Ton

-

Belt Sludge DryerEUR 1 - 1MOQ: 1 Ton

-

High Capacity Rotary DryerEUR 1 - 1MOQ: 1 Ton