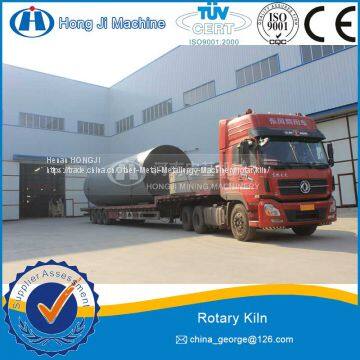

Rotary kiln is a type of industrial dryer employed to reduce or minimize the liquid moisture content of the raw materials, it is handling by bringing it into direct contact with a heated gas.

Product Description

1. Working Process of Rotary Kiln

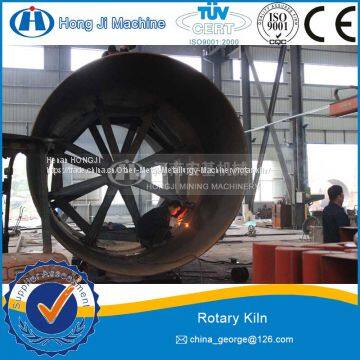

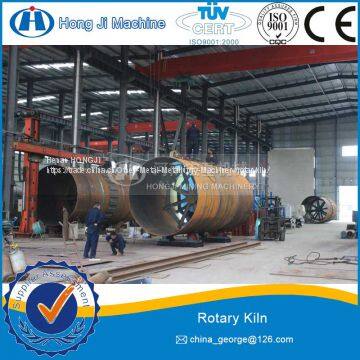

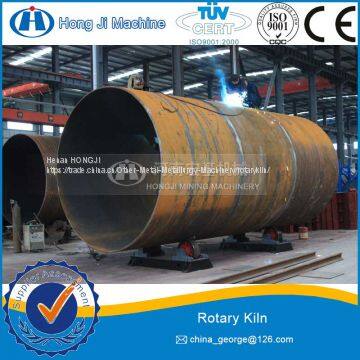

Rotary kiln is made up of a large, rotating cylindrical tube, usually supported by concret columns or steel beams, rotary kiln slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the rotary kiln under gravity. Material to be dried enters the rotary kiln, and as the rotary kiln rotates, the material is lifted up by a series of internal fins lining the inner wall of the rotary kiln. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the rotary kiln, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow).

The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the rotary kiln is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the rotary kiln, the rotary kiln known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern. In some cases, a combination of direct-indirect rotary kiln dryers are also available to improve the overall efficiency.

2. Range of Application for Rotary Kiln Dryer

Mineral Industry: coal, coal sludge, gypsum, sand, coal slime, lignite, ore, etc.

Chemical Industry: silica, fertilizer, etc.

Food Industry: granular material such as food grains, cereals, pulses, coffee beans, fermented tea leaves, etc. wheat, rice, mushroom, grain cassava, etc.

Others: wood, sawdust, animal manure, etc.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Liime KilnEUR 1 - 1MOQ: 1 Ton

-

Rotary Kiln Sampah Domestik GresikEUR 1 - 1MOQ: 1 Ton

-

Cement Calciner Kiln PriceEUR 1 - 1MOQ: 1 Ton

-

Ducting Tod di Kiln CementEUR 1 - 1MOQ: 1 Ton

-

Pengertian Tungku Rotary KilnEUR 1 - 1MOQ: 1 Ton

-

Rotary Drum DryerEUR 1 - 1MOQ: 1 Ton

-

Perhitungan Beban Rotary DryerEUR 1 - 1MOQ: 1 Ton

-

Coal Drying PolandEUR 1 - 1MOQ: 1 Ton

-

Pemanas Rotary Dryer Dengan Bahan ArangEUR 1 - 1MOQ: 1 Ton

-

Typical Cost of Drying CoalEUR 1 - 1MOQ: 1 Ton