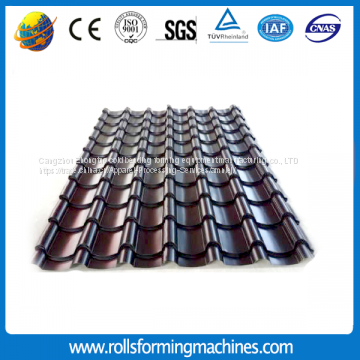

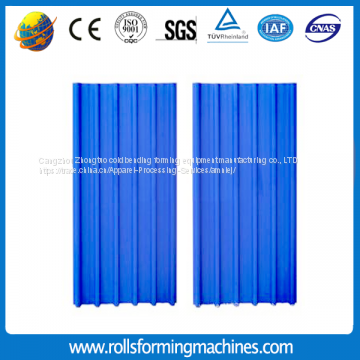

Double Layer Roof Producing Manufacturing Line

Double Layer Roof Producing Manufacturing Line

Colored steel are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets,

shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and

different kinds of greenhouses. What's more, equipment can be designed and manufactured as customers'

requests.

Components of steel sheet roll forming machine

| No. | Name | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main forming machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

steel sheet roll forming machine Production Process:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→

Products receiving

Details of steel sheet roll forming machine:

Parameters:

| No. | Main Parameters of Double Layer Roll Forming machine | |

| 1 | Suitable to process | Colored Steel plate, galvanized board, aluminum plate |

| 2 | Control system | PLC control |

| 3 | Productivity | 15-20m/min |

| 4 | Width of the raw material | 1250mm |

| 5 | Thickness of the plate | 0.3-0.6mm |

| 6 | Rollers | Up layer:13 rows Down layer:18 rows |

| 7 | Diameter of the rollers | 70mm |

| 8 | Rolling galvanization thickness | 0.05mm |

| 9 | Material of the cutting blade | Cr12 |

| 10 | Dimension | 9.2m*1.6m*1.4m |

| 11 | Weight | About 13.2T |

| 12 | Voltage | 380V 50Hz 3phases |

| 13 | Power | 5+4kw |

Raw materials

Packaging Detail of steel sheet roll forming machine:

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Send Inquiry to This Supplier

You May Also Like

-

C Purlin Z Purlin U Purlin MachineNegotiableMOQ: 1 Bag

-

After Forming Cutting Purlin MachineNegotiableMOQ: 1 Bag

-

Dahezhongbang Intelligent Technology Co., LtdNegotiableMOQ: 1 Bag

-

C Z Quickly Interchange Roll Forming MachineNegotiableMOQ: 1 Bag

-

Single or Double Barbed Wire Galvanized Steel Barbed Wire MachineNegotiableMOQ: 1 Bag

-

Heavy Hexagonal Mesh Double Twist Barbed Wire MachineNegotiableMOQ: 1 Bag

-

Metal Roof Panel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Hot Sale c z Purlin Forming MachineNegotiableMOQ: 1 Bag

-

Used Roller Shutter Roll Forming MachineNegotiableMOQ: 1 Bag

-

Roll Forming Machine for Building MaterialNegotiableMOQ: 1 Bag