Glazed Tile Metal Roof Panel With High Quality Machine

glazed tile metal roof panel with high quality machine

Specifications

1.Machine frame thickness. High quality machine normally has high working speed. So when machine working, the steady ability is very important for you.

2.Machine shaft diameter and roller material. High quality machine can process thicker coil and work long time. So shaft hardness and diameter is very important against bending.

3.The roller material is very important. As for long time using, material will rub roller. Only good quality material can keep perfect shape after long time using.

4.Electrical elements brand. The machine controlled by PLC and powered by motor, so the brand and quality can affect the machine quality too much.

1. Processing flow diagram

Manual decoiler→Feeding material into machine→Roll forming machine→Measure length→Hydraulic cutting→Finished Products

2. Technical parameters

| Model number | glazed tile metal roof panel with high quality machine |

| Rolled material | 0.3-0.8mm thickness, aluminum sheet, galvanized sheet, colored steel sheet and various steel plates |

| Effective width | AS YOUR DESIGN |

| Feeding width | ACCORDING TO YOUR DESIGN |

| Forming steps | 14-18 stations |

| Roller | 45# forged steel, hard chrome plating within 0.05mm |

| Diameter of shaft | 70mm |

| Main motor power | 4 kw |

| Pump power | 3 kw |

| Sprocket chain | 1 inch |

| Drive type | by chain |

| Cutting Blade | Cr12, heat treatment 60-62°C |

| Frequency Converter | It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

| component | 1 set of manual decoiler,1 set of main roll forming machine,1 set of computer control cabinet,1 set of hydraulic System,1 set of cutting mechanism,1 set of counter,1 set of output table |

| Payment terms | cash,T/T,L/C. |

Remark: Above parameters are standard, we can design and make some change exactly according to your requirements.

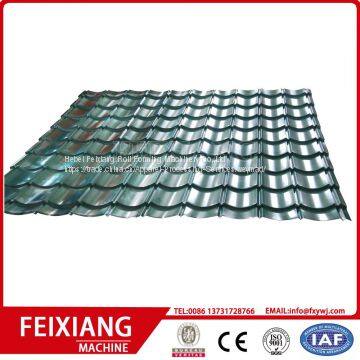

3. Profile and Real photos

4.Details of the machine:

5.After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.

B: Training: the buyer should charge of visa, round-trip ticket, food and accommodation

overseas and USD100/person/day for salary.

C: Need one technician.

D: Training time: one week (contains the time of installation and adjustment)

6.Real Photos of Our Factory. Warmly Welcome to Come and Visit Our Company

7.Certifications for Our Company and Our Machines

8.if any needs or questions on roll forming machines, please feel free to contact me.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Roofing Machine of Glazed Tile Panel MachineNegotiableMOQ: 1 Bag

-

Roof and Wall Glazed Tile Roll Forming MachineNegotiableMOQ: 1 Bag

-

Glazed Tile Double Deck Roll Forming MachineNegotiableMOQ: 1 Bag

-

Metal Roof Glazed Tile Making Forming MachineNegotiableMOQ: 1 Bag

-

Colored Glazed Sheet Tile Roll Forming MachineNegotiableMOQ: 1 Bag

-

312 Ridge Tile Color Steel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Automatic Shutter Door Metal Roll Forming MachineNegotiableMOQ: 1 Bag

-

High Speed Steel Weld Pipe MachineNegotiableMOQ: 1 Bag

-

Steel c Channel MachineNegotiableMOQ: 1 Bag

-

c Section Steel Forming MachineNegotiableMOQ: 1 Bag