High Quality Galvanized Corner Dry Wall Angle Bead Machine

High Quality Galvanized Corner Dry Wall Angle Bead Machine

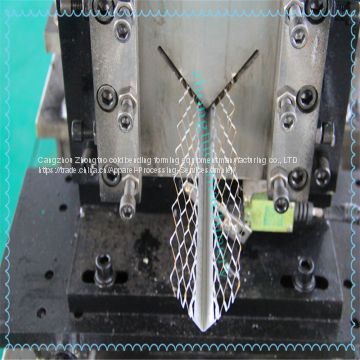

Angle beads are particularly suitable for using in forming straight edges and exterior corners when plastering for arises and columns. They're widely regarded as indispensable to plastering operation. Using appropriate angle beads eliminate the need for fixing and removing timber battens, thus increase efficiency and quality for plastered columns & beams. As to High Quality Galvanized Corner Dry Wall Angle Bead Machine is designed to make those angle beads production fully automatic.

Why we called it high quality Galvanized Corner Dry Wall Angle Bead Machine ;

1. it can help you finsih the production fully automatic.

2. It can reach the working speed of 25m/min.

3. It can use more than 10 years.

4.For the punching die could be fixed and repaired when it is not shape.

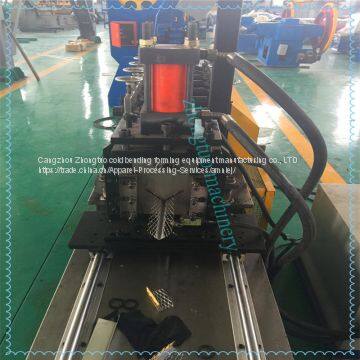

Working speed:110-130 time/min

Main power:3kw

Servo coil feeder with PLC control system

Punching Pressure: 25 Ton

Main roll forming machine:

Length of the main part: about 3500х800х1400Weight of main part:3 tons

Voltage : 380V/50HZ3Phase (as customer`s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:20mm

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers: 9 rollers

Main power: 3 kW

Cycloidal planetary gear speed reducer)

The different sizes can be produced on this machine

by adjusting the feeding width.

For this machine, here is the machine working video for your reference:

/watch?v=WHZfxw1A4t8

When come to real use:

Galvanized steel: SK-50; SK-25. 2. Stainless steel: SK-50S; SK-25S. 3. Length (mm): 2500 / 2700(mm). 4. Qty / box: 50 (pcs). 5. In addition to the above-mentioned specification, we offer customized services, size as customer's demand.

Send Inquiry to This Supplier

You May Also Like

-

Drywall Channel Machine Gypsum Wall Channel Machine CUL Channel Making MachineNegotiableMOQ: 1 Bag

-

High Speed Rotary Punching L Wall Angle Machine High Speed Wall Angle MachineNegotiableMOQ: 1 Bag

-

Rain Gutter Roll Forming Production LineNegotiableMOQ: 1 Bag

-

Steel Water Gutter Roll Forming Production LineNegotiableMOQ: 1 Bag

-

Light Duty Warehouse Pillar Roll Forming MachineNegotiableMOQ: 1 Bag

-

Galvanized Layer Ringlock Scaffolding Roll Forming MachineNegotiableMOQ: 1 Bag

-

Scaffolding Panel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Scaffold Catwalk Panel/scaffold Decking Roll Forming MachineNegotiableMOQ: 1 Bag

-

Professional Punched Stainless Steel Scaffolding Ladder Plank MachineNegotiableMOQ: 1 Bag

-

Steel Floor Plate Roll Forming MachineNegotiableMOQ: 1 Bag