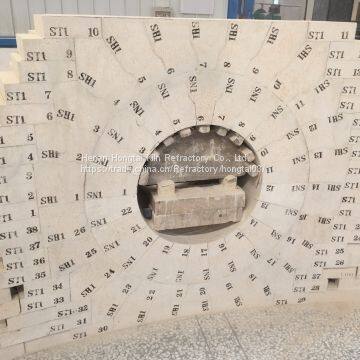

High alumina brick is made by using high bauxite as the main raw material, soft raw clay as a binder, fired in 1500 ℃ high temperature after molding. According to the content of Al2O3, high alumina bricks are divided into three grade: Grade Ⅰ: Al2O3 content is more than 75%,Grade Ⅱ:Al2O3 content is between 60% and 75%, and GradeⅢ: Al2O3 content is between 48% and 60% . Its softening temperature is not less than 1400 ~ 1530 ℃.

Compared with clay bricks, the advantages of high alumina bricks are high refractoriness and high softening temperature. And the slag resistance is improved remarkably With the increase of Al2O3 content.

High alumina bricks have the following properties:

(1) refractoriness

High alumina bricks are senior refractory. Its refractoriness is higher than both of clay brick and semi-silica brick, up to 1750 ~ 1790 ℃. The refractoriness is mainly affected by the content and type of Al2O3, and the refractoriness increases with the increase of Al2O3 content.

(2) refractoriness under load

Because of high content of Al2O3 and small amount of impurities in high alumina brick, the fusible glass formed is less, so the refractoriness under load of high alumina brick is higher than clay brick’. But the mullite crystallization does not form a Reticular organization, so the refractoriness under load is still lower than silicone bricks’.

(3) thermal conductivity

High alumina bricks have better thermal conductivity than clay bricks. The reason is that the glass phase with low thermal conductivity inhigh alumina brick is relatively less, and mullite and corundum crystal with good thermal conductivity are increased.

(4) thermal shock stability

The thermal shock resistance of high alumina bricks is between clay products and siliceous products: only 3 to 5 times in 850 ℃ water cycle. This is mainly due to the thermal expansion of corundum is high than mullite, and no crystal conversion. At present, it is possible to improve the thermal shock resistance of the product by improving the particle structure of the product, reducing the content of the fine powder and improving the Clinker critical particle size and particle gradation.

(5) Slag resistance

High alumina brick content more Al2O3, close to the neutral refractory material, can resist the acid slag and alkaline slag’ erosion. Because it contains SiO2, the ability to resist alkaline slag resistance is weaker than acid slag. In addition, the slag resistance of high alumina bricks is also related to the stability of the product in slag. In general, after high pressure molding and high temperature firing, products with lower porosity have higher slag resistance.

High alumina brick parameters have a wide range of changes, so its physical properties should be determined according to the product grade and and using places in the use of bricks. High alumina brick indicator is the basic performance requirements, according to the use conditions, the creep resistance and thermal shock resistance should also be considered. Chemical erosion resistance is directly dependent on A12O3 content and porosity.

advanced fire clay high alumina refractory bricks

Send Inquiry to This Supplier

You May Also Like

-

High Wear Resistant and Affordable Corrosion Resistant Alumina Lining PlateNegotiableMOQ: 1 Meter

-

For Cinema Shop Low Noise High Efficiency Bricks MachineUS$ 1000 - 11000MOQ: 1 Unit

-

High Speed Aseptic Bricks UHT Milk Filling SystemNegotiableMOQ: 1

-

Aviation Aluminum Zero-clearance Drive Non-slip High Alumina Alloy CouplingNegotiableMOQ: 1

-

Compression Testing Machine for Refractory Bricks High-temperature Material Strength Testing MachineUS$ 4000 - 6000MOQ: 1 Set

-

High Quality HST-HB3000ETZW Digital Automatic Brick Tower Brinell Hardness TesterUS$ 4490 - 5280MOQ: 1 Set

-

High Quality Hammer Drill Bit Multipurpose Drill Bits for Ceramic Glass & Common BrickNegotiableMOQ: 50 Pieces

-

High Alumina Lining Bricks for Ball Mill With Competitive Price ISO 9001 and High Capacity From Henan Hongji OEMUS$ 8,000 - 16,000MOQ: 1 Set

-

High Alumina Ceramic TubeUS$ 0.05 - 5MOQ: 1000 Pieces

-

5-8mm Refractory Brick Raw Material White Fused Alumina for SaleUS$ 730 - 800MOQ: 1 Ton