Iron Ore Production Line of Flotation Separator for Iron Concentrate

Iron ore production line of flotation separator for iron concentrate

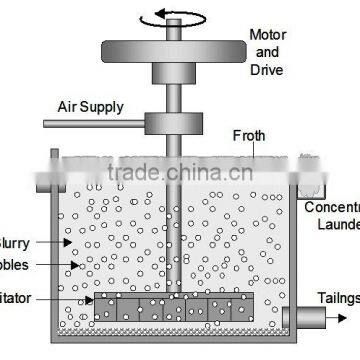

Flotation separator is a machine that is used for completing the flotation separation process. Inside the flotation cells, the ore pulp processed with reagent is mixed and inflated with air to make some ore particles selectively adhere to the bubbles. Then the bubbles will float to the surface of the ore pulp and be scraped out to become froth pulp and the rest will remain in the ore pulp, thus reaching the aim of separating the minerals.

Flotation separator working principle:

Mix the mashed rocks with water and necessary reagent in the mixing chute, and inject them to the pulp chute. Lead air to the pulp to make it form large quantities of bubbles, and some mineral particles that are difficult to get moist in water and that are generally called hydrophobic mineral particles will stick on the bubbles and float with the bubbles to the surface of the pulp to form mineralized bubble layer, and some other mineral particles that are easy to get moist in water and that are called hydrophilic mineral particles do not stick on the bubbles but stay in the pulp to discharge the mineralized bubbles containing specific minerals, thus completing the separation process.

Flotation separator technical parameter:

Flotation separator for iron ore:

1.Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for classifying. After classifying, the parts whose size below the mesh size will be transferred away as final products, while the other parts will return to cone crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

2.The smaller crushed iron ore is fed to ball mill for grinding. Inside the ball mill, the crushed iron ore will grind the ore to about 0.2 mm with 3-inch steel balls.

3.This iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation cell with the fine sulfide ore (~-0.074 mm) going to froth flotation cells for recovery of iron.

If you are interested in our flotation separator production line, please tell me your raw ore, production capacity and final product you need, then i offer you detailed information.

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set