SF Flotation Cell for Iron Production Line

SF flotation cell for iron production line

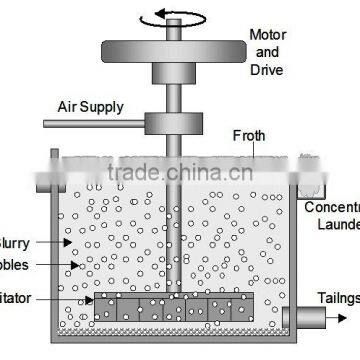

Flotation machine is also known as flotation cell and flotation tank, which is one kind of ore processing equipment mainly used to separate copper, zinc, lead, nickel, gold, silver, lead and other non-ferrous metals. So, it is also called gold flotation machine,copper ore flotation machine, iron ore flotation cell.

There are a lot of iron ore in nature, which containes highly quantities of hematite or magnetite.The mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etc.

Working Process of SF flotation cell:

1.Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for classifying. After classifying, the parts whose size below the mesh size will be transferred away as final products, while the other parts will return to cone crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

2.The smaller crushed iron ore is fed to ball mill for grinding. Inside the ball mill, the crushed iron ore will grind the ore to about 0.2 mm with 3-inch steel balls.

3.This iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation cell with the fine sulfide ore (~-0.074 mm) going to froth flotation cells for recovery of iron.

Technical parameter of SF flotation cell:

Model | SF0.37 | SF0.7 | SF1.2 | SF2.8 | SF4 |

Trough volume(m3) | 0.37 | 0.7 | 1.2 | 2.8 | 4 |

Impeller diameter(mm) | 300 | 350 | 450 | 550 | 650 |

capacity(m2/min) | 0.2-0.4 | 0.3-0.9 | 0.6-1.2 | 1.5-3.5 | 0.5-4 |

Impeller speed(r/min) | 352 | 400 | 312 | 268 | 238 |

Model of motor Power of motor(kw) dimensions(mm) single trough weight(kg) | Y90L-4 | Y100L2-4 | Y132M2-6 | Y160L-6 | Y180L-6 |

Y90S-4 | Y90S-4 | Y90S-4 | Y90S-4 | Y90L-4 | |

1.5 | 3 | 5.5 | 11 | 15 | |

1.1 | 1.1 | 1.1 | 1.1 | 1.5 | |

700X700X750 | 900X820X950 | 1100X1100X1100 | 1700X1600X1150 | 1850X2050X1200 | |

468 | 600 | 1373 | 2338 | 2660 |

XJF flotation cell:

| Model | Volume | Impeller dia(mm) | Capacity(m3/min) | Impeller speed(r/min) | Scraper speed(r/min) | Dimensions | Weight(t) |

| L*W*H(mm) | |||||||

| XJK-0.13(1A) | 0.13 | 200 | 0.05-0.16 | 600 | 17.5 | 2110*865*990 | 0.35 |

| XJK-0.23(2A) | 0.23 | 250 | 0.12-0.28 | 500 | 17.5 | 2625*1130*1290 | 0.42 |

| XJK-0.35(3A ) | 0.35 | 300 | 0.18-0.4 | 470 | 17.5 | 3012*1350*1327 | 0.45 |

| XJK-0.62(4A) | 0.62 | 350 | 0.3-0.9 | 400 | 26 | 3798*1464*1530 | 0.85 |

| XJK-1.1(5A) | 1.1 | 500 | 0.6-1.6 | 330 | 26 | 4679*1820*1942 | 1.24 |

| XJK-2.8(6A) | 2.8 | 600 | 1.5-3.5 | 280 | 26 | 7750*1600*1100 | 2.43 |

Flotation cell production line:

Feeder------Jaw crusher------Cone crusher------Elevator------Ball mill------Jigger machine------Concentrator------Ball mill------Flotation cell------Magnetic machine------Tailing recycling machine

Flotation cell shipping:

Flotation cell working site:

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set