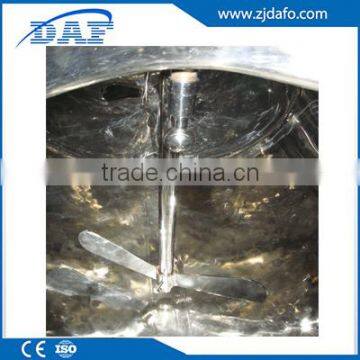

Stainless Steel Mixing Tanks/Agitator Tanks

Product Name:

Stainless steel Mixing tanks/Agitator tanks

Application field:

1. Used for material mixing tank(heating), disinfection tank, aging tank, fermentation tank, agitation tank, etc.

2. Suitable for many fields such as dairy, juice, beverage, medicine chemical or bio-engineering project, etc.

Structure:

1. Single layer structure, dual-layer with Jacket or Insulation,three layer with double jacket.

2. High quality stainless steel 304 or 316L available.

3. Humanized structure design & easy to operate;

4. Transition area of interior wall on tank adopts arc for transition to ensure no dead corner of sanitation;

5. PU Foam Insulation are available to keep temperature.

Configuration:

1. Flanged cover open.

2. 360 degree rotation CIP spraying ball;

3. Sanitary breathing cover

4. Mixer: Paddle; Frame; Impeller, Be Vertical or Horizontal to choose;

(Top, bottom side & bottom, etc. places to set the mixer)

5. PU foam Insulation

6. Thermometer , Liquid level meter & ladder (According to customer requirements)

7. Other accessories can make according to customer's special requirements.

Main technical parameter:

| Model | Normal volume(L) | Diameter(mm) | Hight(mm) | Diameter of inlet outlet | Motor (kw) |

Rotating speed(RPM) |

| GMT-0.6 | 600 | 1070 | 2140 | 38 | 0.75 | 36 |

| GMT -1 | 1000 | 1220 | 2380 | 38 | 1.1 | 36 |

| GMT-1.5 | 1500 | 1350 | 2550 | 38 | 1.1 | 36 |

| GMT -2 | 2000 | 1510 | 2760 | 38 | 1.1 | 36 |

| GMT-2.5 | 2500 | 1590 | 2940 | 51 | 1.5 | 36 |

| GMT-3 | 3000 | 1710 | 3050 | 51 | 1.5 | 36 |

| GMT-3.5 | 3500 | 1770 | 3180 | 51 | 1.5 | 36 |

| GMT -4 | 4000 | 1820 | 3200 | 51 | 1.5 | 36 |

| GMT-5 | 5000 | 1950 | 3250 | 51 | 1.5 | 36 |

| GMT-8 | 8000 | 2270 | 3900 | 51 | 2.2. | 36 |

| GMT-10 | 10000 | 2470 | 4050 | 65 | 2.2 | 36 |

| GMT-15 | 15000 | 2820 | 4450 | 65 | 2.2 | 36 |

Various Kinds Of Mixing tanks/Agitator tanks

Our company’s advantages over other companies:

Advanced Technology Co., Ltd Wenzhou is the a professional Stainless steel Mixing Equipment,Tank Pressure Vessels,Filters,Beer equipment and brewing technology supplier, who can professionally design, research and develop, and manufacture these equipment.

We can provide clients one-stop service from design, layout, to finished products. Its main business includes beer equipment, self brewing equipment, hotel beer equipment, draft beer dispenser, school laboratory equipment, etc. We mainly provide the capacity 500L/DF, 1000L/DF, 2000L/DF, 3000L/DF, 5000L/D,10000L/D,20000L/D etc.

Our staff of Sales and Technical Support is available to help you in selecting the right protection for your application as well as to provide you with Samples of our products for evaluation. At Advanced Tech., we are committed to providing the Highest level of customer service, Competitive pricing, Speedy delivery and a Comprehensive, cutting-edge product offering. Our ultimate goal is your satisfaction.

We can produce by many standards such as ISO, ANSI, GB, SH, HGJ, DIN, QB, JB, 3A, IDF etc., or by customer’s drawing. The company passed the ISO9001 quality management system certification, with advanced production technology, modern management model, and high-quality staff service for you .

Shipment

Bulk cargo: standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the equipment’s surface.

Container cargo: equipment will be bound firmly,won’t easily swing to the side, or up, or down.

Send Inquiry to This Supplier

You May Also Like

-

Vertical Double Jacketed Stainless Steel Mixing Agitator TankNegotiableMOQ: 1

-

Gas TankUS$ 1200 - 2500MOQ: 1 Piece

-

Factory Directly Sale High Quality Milk Transportation Tank Milk Cooling Tank PriceUS$ 2,000 - 20,000MOQ: 1 Set

-

Steam Heating Double Jacket Agitator Mixing TankUS$ 2,500 - 3,000MOQ: 1 Unit

-

5m3 Factory Supply Liquid Nitrogen Storage Tank With Best QualityUS$ 15,880 - 17,960MOQ: 1 Set

-

Rotomold Auto Fuel Tank Water TankUS$ 20 - 200MOQ: 1 Set

-

Low Temperature Circulating Water Thermostatic Tank Temperature Test Laboratory Use Heating Cool Cycle WaterUS$ 700 - 758MOQ: 3 Sets

-

Prefabricated Large Diameter Water Diesel Fuel Oil Gas LPG Chemical Storage Tanks With Fabrication ServiceUS$ 2,000 - 3,500MOQ: 1

-

China Honglu Light Steel Structure Gas StationUS$ 1,300 - 1,400MOQ: 22 Tons

-

Electric Tank/slurry TankNegotiableMOQ: 1 Set