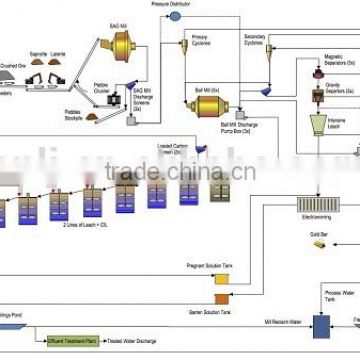

Gold ore cyanidation and carbon in leaching process :

Gold Mining Equipment- Gold CIL (carbon in leaching)Plant line mainly include following equipment:

Vibrating Feeder

Jaw crusher, cone crusher

Vibrating screen

Belt conveyors

Ball mill

Spiral classifer

Hydrocyclone

Thickener

Leaching Tanks

Electrowinning and desorption device

Gold smelting furnace

CIL plant consists of following steps:

1 The ore is first reduced in size (typically 80% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold

industry, such as: Multi-stage crushing, then ball milling circuits, typical of ball mill and hyrocyclones.

2 Thickening(add lime flocculant)

After comminution the pump is normally dilute and thickening. High efficient thickener is performed to increase the pulp density to about 50% solids by mass.

3 Leaching

Leaching reagents in the form of cyanide and and oxidant such as air or oxygen are added after thickening. Leaching take place in a series of agitated leaching reactors.

4 Carbon adsorption

After leaching, the pulp is passed over a feed screen to ensure removal of tramp materials about 0.6mm. This is done to minimize screen blocking in the adsorption section. After feed pre-screening, the pulp flows trough a cascade of well mixed adsorption tanks, typically 6-8 in number. The pulp residence time is about one hour in each tank. The tanks are normally mechanically agitated and each will contain a batch of carbon of concentration 10-25grams of carbon per litr of pulp. The carbon size is 0.6-0.8mm. The gold recovery is 90-99%.

5 Desorption and electro-winning

The loaded carbon is processed by desorption and electro-winning set, by this solution, it gets grain gold.

6 Gold melting

If you are in the market for gold cyanide leaching production line, welcome to contact us, we can provide you complete set machine and one step services.

Contact : Ms Sara

Mobile phone : 008613783471727

Skype : sarapang6

website:

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set