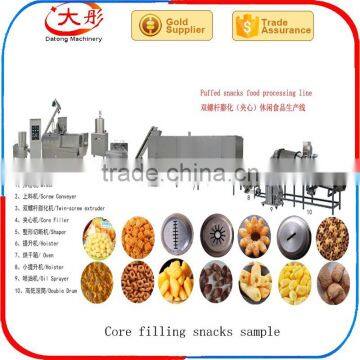

1.Core Filled Snack Food Processing Line details:

1.Filled puffed snacks are directly expanded snacks co-extruded with creamy and sweet pastes. They are particularly innovative and easily adaptable to meet changing consumer demand.

2.A typical co-extrusion processing line includes mixing and oil spraying systems, a twin-screw extruder at the heart of the process and shaping equipment. Drying, coating and cooling devices are then used accordingly.

3.Extruded flakes can also be made on the same lines with complementary equipment.

2.Ingredient flexibility to process a wide variety of :

1.Outer parts with various materials : wheat, rice, corn, whole grain etc.

2.Fillings : chocolate flavors, jellies, fruit pastes, honey, yoghurt, etc.

3.Shapes : pillows, tubes, bars, triangles, nuts, balls, long and short ovals and specialty profiles, etc.

4.Expertly crafted co-extrusion dies with optimized flow design.

5. The Core Filled Snack Food Processing Line list:

Mixer→ Screw conveyor → Twin screw extruder→ Core filling machine→ Shaping and cutting machine→ Air conveyor(Hoister)→ Electric dryer → Hoister → Oil Sprayer→ Flavoring roller(drum) → Cooling conveyor

3.Machine Parameter&Processing Chart:

4.Core Filled Snack Food Processing Line Main Features:

1) Raw materials: corn,rice,wheat,oat,barley etc.

2) products shape: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel, flower, star and heart

shape by adjusting the mould in the extruder, can custom-made the shape

3) Easily to operater the whole line. Only need three workers to control the processing line

4) Low power consumption

5) Long life and cheap spare parts.

5.Product Certificate:

6.Install drawing for Core Filled Snack Food Processing Line:

7.Core Filled Snack Food Processing Line Features:

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3.The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, it makes extruder can be used not only for corn/rice, also for wheat flour/starch which are raw materials with high viscosity. Through different moisture-extrusion temperature ratio, it can make whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Raw material Mixer:

1.Main motor: 4.0kw

2. Size: 1.2×0.9×1.4(m)

3. Output: 30kg-40kg/time

Functions:

Mixer makes the raw material which adding water and liquid chemical additive fully mixed equally. the machine mixes the flour and prepares them ready to be used in the next step.

Screw Conveyer:

Output: 0-150kg/h

Main motor:1.1kw

Size: 2500*600*2300mm

Function:

Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution.

Double Screw Extruder:

Installed Capacity:45.87kw Drive Motor:30kw;

Feeding:0.75kw; Oil-pump: 0.37kw;

Cutting: 0.75kw; Output: 200-240kg/h

Dimension: 2600*950*1750mm

Main Features:

1.The main extruder motor,cutting motor adopts frequency speed controlling with high automation and stable per-formation.we can adjust the motor speec according to our require easily, it can meet human safe level.

2. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer,adopt 38CrMnAl.the screw can used long time.

3. This extruder have forced lubrication system, so that it can guarantee the equipment gear transmission and cooling the bearing

4.Auto-temperature control system make the temperature controlling more direct viewing and the parameter more precise.

5.This extruder have Self-cleaning, when stopping, it can be cleaned without disassembling.No need to take out the twin screw to clean it.

6.SLG Series Double screw Extruder is mainly composed by the following parts,evry part paly different role:

A Feeding System B Extruding System

C Cutting System D Heating System

E Lubrication System F Driving System

G Electricity Control System

Hoister:

Food types PVC for material touch place.

Main Motor:1.2kw

Size:2.0x0.5x2.8 (m)

Convey the product from dryer to double roller.

Electricity Dryer:

1. This dryer has the compact structure, small occupying, large drying area, small surface area, slight radiating heat and high thermal efficiency.

2.The belt and the heat preservation use the stainless steel; it is suitable for food safe industry level.

3.The running speed of belt net can be controlled (frequency controlling system)

4.The temperature can be controlled willfully and designed according to the need.

5. Adjustable transit speed of net belt with accurate temperature control device.

6. Suitable to dry non-fried extrusion snacks, nutritional powder, bread crumb, Fish food, soybean protein, etc.

Flavouring System:

Output:100-250kg/h

Size:3.9x0.7x1.3(m)

Mian power: 1.5kw

1.The inside turning container is very sanitary because of adopting the stainless steel material. The small roller is used for the small output whereas the big roller is used for the plentiful output.

2.we can spray the oil and sprinkle flavoring material in this First drum,we can flavoring products automatically.this drum is easy to operate it.and easy to clean it after day work.

Pillow Packing Machine:

1. Performance and structural characteristics

*Advanced dual frequency control, flexible to control the length of bag, saving time and film.

*Manual operation machine, convenient and quick parameter setting

*Fault self diagnosis function, clear failure display.

*The digital input of the high precision photoelectric tracking system, sealing and cutting more precise, .

*The independent PID temperature control, suitable for all kinds of packaging materials.

*The positioning stop function, non stick knives, do not waste film.

2. Packaging range

Applicable to the towel, facial tissue paper, medicine, Chicken rolls, noodles, fish, sausage,

popsicle, candy, cookies, fruit and other soft, strip or irregular goods packaging.

Jinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty for Extruded Food Wheat Corn Snack Pellet Making Machine.

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

3) What’s the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.

Packing: inside plastic bag, outside wooden case for core filling snack food puffed food making machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, train, express or upon clients' demands.

Packing machine with woodcase and plastic flim

Loading container in our factory

Send Inquiry to This Supplier

You May Also Like

-

New Technology Fully Automatic Corn Flakes Making MachineUS$ 20,000 - 40,000MOQ: 1 Set

-

Corn Flake Making Machine Processing LineUS$ 20,000 - 40,000MOQ: 1 Set

-

China Supplier Small Corn Flakes Making MachineUS$ 20,000 - 40,000MOQ: 1 Set

-

High Quality Corn Puff Snack Extruder Making MachineUS$ 20,000 - 40,000MOQ: 1 Set

-

Delicious Puffed Snack Food Making MachineUS$ 20,000 - 40,000MOQ: 1 Set

-

Puffed Snack Corn Flakes Making MachineUS$ 20,000 - 25,000MOQ: 1 Set

-

Manufactory Puff Corn Snack Food Production EquipmentUS$ 19,998 - 20,000MOQ: 1 Set

-

Hot Puff Corn Snack Food Production ExtruderUS$ 19,998 - 20,000MOQ: 1 Set

-

Good Supplier Puff Corn Snack Food Processing EquipmentUS$ 19,998 - 20,000MOQ: 1 Set

-

Different Price Puff Corn Snack Food Processing ExtruderUS$ 19,998 - 20,000MOQ: 1 Set