High Performance Heavy Flow Slurry Pump

High Performance Heavy Flow Slurry Pump

Overview for High Performance Heavy Flow Slurry Pump

AM 100m High Pressure abrasion resist mining slurry pump are horizontal, axial-suction, single-stage, single-suction and centrifugal slurry pumps.

The AM serial pumps have the advantages over similar products both at home and abroad because of the innovation in the aspects of hydraulic design, structural design and materials of flow passage components.

The main feature of this serial pumps are that they are highly efficient, energy-conservative, small vibration, low noise producing, reliable in operation, have a long service life and are easy to maintain.

Application for High Performance Centrifugal Large Capacity Flow Slurry Pump

AM Pump are applied in the transport of abrasive paste along with solid particles in the generation of electric power, metallurgy, coal, building materials and other industries such as hydraulic ash removal of fuel electric plant, pulp transport of metallurgical dressing plant, coal paste and dense media transport of coal washery.

Working conditions:

| Mineral Processing | Mill Grinding | Chemical Slurry Service | Food Processing |

| Cyclone Feeds | Pulp and Paper | Ash Handling | Cyclone feed |

| Flotation | Coal washery | Power plant | Iron Ore Dressing Plant |

| Potash Fertilizer Plant | Alumina Industry | Sand Excavation | Mineral Concentration Plant |

Main Parameter for High Performance Heavy Flow Slurry Pump

The pump have a wide performance range, good cavitation performance and high efficiency.

Specification:

Capacity (m3/h):5000m3/h

Head (m):90m

Speed (r/min):800-3000

Max. Efficiency %:90

NPSH (m): 3-5

Model Meanings for High Performance Heavy Flow Slurry Pump

Model 6x4E-AMR

6x4: Inlet x outlet diamater(mm)

E: Bearing housing frame type

AM: Series model for slurry pump

R: Rubber lined material

Performance Curve Chart for High Performance Heavy Flow Slurry Pump

Performance Table List for High Performance Heavy Flow Slurry Pump

Construction Drawing for High Performance Heavy Flow Slurry Pump

Construction Features for High Performance Heavy Flow Slurry Pump

| Liners | Wide variety of metallurgic and elastomeric options (metal and elastomer interchangeable); |

| Throat Bush | Hard metal and molded elastomer impellers are completely interchangeable. Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. |

| Impeller | Hard metal and molded elastomer impellers are completely interchangeable. Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. |

| Casing | Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. |

| Shaft | With large shaft diameters, heavy duty bearing assemblies and robust slurry pumping capacity, AN PUMP slurry pumps provide a cost-effective and ideal alternative to longer lead times and engineering services that are often costly or not available elsewhere. |

| Shaft seal | The seal of shaft can adopt gland seal , expeller seal or mechanical seal. |

| Nozzel | Discharge branch nozzel can be positioned at 8 different positions at intervals of 45° |

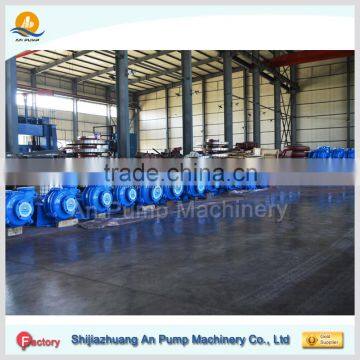

Packaging for High Performance Heavy Flow Slurry Pump

Shipping for High Performance Heavy Flow Slurry Pump

Offer 100m High Pressure abrasion resist mining slurry pump solution, design, manufacturing, and after-sales service.

Serivece for High Performance Heavy Flow Slurry Pump

Service | Specification |

1. Selection | Send us working data (medium, head, flow rate...) |

2. OEM/ODM | Please show us the pump design drawing |

3. Process design | Offer process design as working condition. |

Contact AN PUMP

Ailen

Send Inquiry to This Supplier

You May Also Like

-

Spot Danfoss Piston Pump JR-L-S75C-LS-21-25-NN-N3-S1NE-A2NNNN-JJ J-NNNNegotiableMOQ: 1 Piece

-

M, AH, HH Series Slurry PumpNegotiableMOQ: 1 Piece

-

304 Stainless Steel Industrial Water Pump 220V 50Hz 3HPUS$ 10000MOQ: 1000 Tons

-

Japan Komatsu PC200-8 PC210-8 PC220-8 Excavator 708-2L-31430 Hydraulic Main Pump 7082L31430US$ 4000 - 5000MOQ: 1 Unit

-

Rexroth PGF1-21/1.7RA01VP1 Type Hydraulic Internal Gear PumpUS$ 120.36 - 229.87MOQ: 1 Set

-

Innovative CMO GHIBLI FOOT PUMP Industrial Solutions for Enhanced PerformanceNegotiableMOQ: 1 Set

-

Manufacturer Direct Selling Fluorine Lined Strong Acid and Alkali Resistant Pump IHF Series Fluorine Plastic Alloy Chemical Centrifugal PumpUS$ 150 - 1600MOQ: 10 Pieces

-

Sand Pumping PumpUS$ 410 - 700MOQ: 1 Piece

-

Micro Machining Precision Casting Water Pump Spare PartsUS$ 1 - 30MOQ: 500 Pieces

-

Parts Of Breast PumpUS$ 1,000 - 1,100MOQ: 2 Tons