CE STANDARD HIGH PERFORMANCE DISPOSABLE PLATES MAKING MACHINE

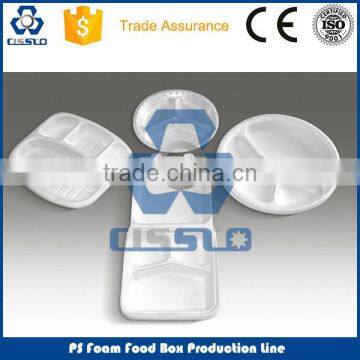

DISPOSABLE PLATES MAKING MACHINE

1. HLSJPS Series High Foaming Polystyrene Sheet Extruder Unit

1.1 Product details

CissCo is the invigation to supply high foaming polystyrene sheet extruder unit in the market. We have more than 20 years experience in developing and manufacturing this unit. After constant improvement, the machine has the features: high capacity, low power consumption, stable performance, high automation and high quality products.

The high foaming polystyrene sheet extruder unit is mainly used in food packaging, such as food boxes, plates, bowls, industrial protecting packaging, KD board and also can also be used as the thermal insulation and sound- proof material.

1.2 The high foaming polystyrene sheet extruder unit has the following advantages:

•Optimal designed precise screws.

• Equip with precise extrusion elements

•Special designed end of second stage extruder to ensure no leakage.

• With static mixing elements to ensure uniformity of plasticized.

1.3 Main Technical Parameters:

Model Parameters |

Unit |

HLSJPS- 70/90 |

HLSJPS- 80/100 |

HLSJPS- 90/120 |

HLSJPS- 100/310 |

HLSJPS- 120/150 |

Capacity |

Kg/h |

90-110 |

110-150 |

170-210 |

250-310 |

370-500 |

Sheet thickness |

mm |

1.2-5 |

1.2-6 |

1.2-6 |

1.2-6 |

1.2-6 |

Sheet width |

mm |

500-1100 |

600-1300 |

1000-2000 |

1000-2000 |

1000-2000 |

Foaming ratio |

times |

11-30 |

11-30 |

11-30 |

11-30 |

11-30 |

Density |

kg/m3 |

33-90 |

33-90 |

18-30 |

18-30 |

18-30 |

Length diameter ratio |

L/D |

36/1,33/1 |

36/1,33/1 |

36/1,33/1 |

35/1,33/1 |

35/1,33/1 |

Cooling type |

Air cooling for first stage extruder,water cooling for second stage extruder |

|||||

Liner speed |

m/min |

5-30 |

5-30 |

5-40 |

5-40 |

5-40 |

Center height |

MM |

1100 |

1100 |

1100 |

1100 |

1100 |

Compressed air pressure |

Mpa |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

Compressed air amount |

m3/min |

0.4 |

0.6 |

0.8 |

1.1 |

1.5 |

Butane injection pressure |

Mpa |

1 |

1 |

1 |

1 |

1 |

Cooling water amount |

T/H |

6 |

8 |

11 |

13 |

18 |

Cooling water pressure |

Mpa |

≥0.2 |

≥0.2 |

≥0.2 |

≥0.2 |

≥0.2 |

Weight of whole machine |

T |

11 |

13 |

15 |

18 |

22 |

Installation size(L*W*H) |

M |

25×4×3 |

26×4×3 |

27×4×3 |

33×5×3 |

33×5×3 |

2. Food Box Foaming and Trimming Line

2.1 Product details

HLRCH series high speed thermoforming machine and HLZCZ automatic in-line punch press consist of fully automatic forming ,punch cutting and automatic stacking which are the new generation developed by us This line has high efficiency in producing , perfect cutting performance, easy operataion, high durability and trouble free of punching mould (generally more than 8 years) .

HLRCH series high speed thermoforming machine equipped fully servo system on sheet feeding and forming, which can provide high efficiency cycle time within 2 sec/cycle and high accurate , and can make high quality in forming with 60 Tons clamping force It is suitable for vacuum forming , press forming and vacuum pressing process. EPS, PVC, PP, BOPS, HIPS, PLA and PET sheet are suitable for this machine.

2.2 High speed thermoforming series technical specifications:

Model Parameters |

Unit |

HLRCH- 760/1010 |

HLRCH- 1060/1300 |

HLRCH- 1100/1300 |

HLRCH- 1300/1300 |

HLRCH- 1300/1420 |

Max.forming area |

mm2 |

762*1016 |

1065*1295 |

1120*1295 |

1270*1295 |

1270*1420 |

(30"*40") |

(42"*51") |

(44"*51") |

(50"*51") |

(50"*56") |

||

Max.forming depth |

mm |

127(5") |

127(5") |

127(5") |

127(5") |

127(5") |

Mould Clamp Force |

T |

40 |

60 |

60 |

60 |

60 |

Max.formingspeed |

s/die |

1.8 |

2 |

2 |

2 |

2 |

Oven length |

mm |

3000 |

5300 |

5300 |

5300 |

5600 |

Mounted capacity |

kw |

110 |

315 |

330 |

365 |

400 |

Weight |

T |

7 |

10 |

11 |

14 |

16 |

Intallation size(L*W*H) |

m |

10*2*2.5 |

14*2.2*2.5 |

14*2.2*2.5 |

14*2.35*2.5 |

15*2.35*2.5 |

3. Pictures of PS Foam Fast Food Box Extrusion, Forming and Trimming machine:

• We design, engineer and manufacture and customized the extrusion line.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 20 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

Send Inquiry to This Supplier

You May Also Like

-

Multi-Purpose Foam Hot Melt Machine for EPS Foam, Lunch Boxes & Insulation Material RecyclingNegotiableMOQ: 1 Set

-

CE APPROVED XPE Foaming MachineUS$ 1,000 - 50,000MOQ: 1 Set

-

Best Used Protable pu Foam Machines for Roof PanelUS$ 1 - 6,000MOQ: 1 Set

-

Plastic Machinery With Competitive PriceUS$ 1,000 - 3,000MOQ: 1 Set

-

EPS Polystyrene Foam Cup Making MachineUS$ 9,000 - 290,000MOQ: 1 Set

-

Large-capacity Low-cost Icf Machine for Blocks Made of Eps and CementUS$ 250,000 - 500,000MOQ: 1 Set

-

Waste Foam Hot Melt Processing Machine for Insulation Board & Disposable Food Container RecyclingNegotiableMOQ: 1 Set

-

Waste Foam Hot Melt Machine for Converting Home Appliance Packaging to Extruded Foam BoardNegotiableMOQ: 1 Set

-

Automatic Foam Hot Melt Machine Foam Hot Melt Machine for Shoe Manufacturing With 1-Year WarrantyNegotiableMOQ: 1 Set

-

Foam Hot Melt Machine With Dual Nozzles for Precision Bonding in Automotive IndustryNegotiableMOQ: 1 Set