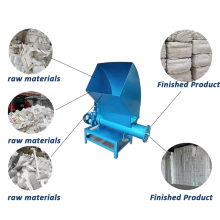

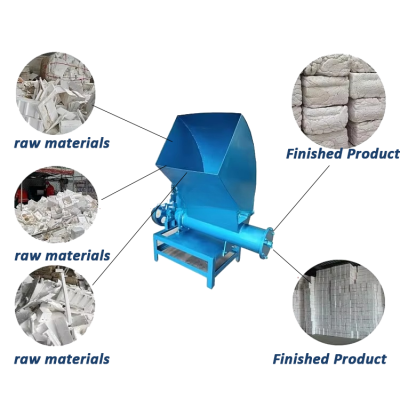

Waste Foam Hot Melt Machine for Converting Home Appliance Packaging to Extruded Foam Board

As a leading manufacturer established in 2019, Henan Panqi Heavy Industry Technology Co., Ltd. proudly introduces our Waste Foam Hot Melt Machine, engineered to transform discarded home appliance packaging into high-quality extruded foam boards. With our 10,000-30,000 square meter factory and a dedicated team of 51-100 professionals, we deliver innovative recycling solutions that reduce waste and boost efficiency. This machine represents our commitment to sustainability and cost-effectiveness, helping businesses worldwide turn foam waste into valuable resources. Backed by an annual export value of US$5 Million - US$10 Million, we ensure reliable, high-performance equipment tailored for modern recycling challenges.

Our Waste Foam Hot Melt Machine excels in converting EPS, EPP, and other foam types from packaging into durable extruded boards, ideal for reuse in construction or manufacturing. Key features include:

- Advanced Hot Melt Technology: Utilizes precise temperature control (180-220°C) to melt foam efficiently, minimizing energy consumption and ensuring consistent output quality.

- Automated Operation: Equipped with an intelligent control system for easy monitoring and adjustment, reducing manual labor and operational errors.

- Robust Construction: Made from durable stainless steel, it withstands heavy-duty use and offers long-term reliability with minimal maintenance.

- Versatile Applications: Perfect for recycling foam from appliances like refrigerators or TVs, with outputs customizable for various thicknesses and densities.

- Environmental Benefits: Reduces landfill waste by up to 90%, lowers disposal costs, and supports circular economy initiatives.

Technical specifications are outlined in the table below for clarity:

| Parameter | Value | Details |

|---|---|---|

| Processing Capacity | 100-200 kg/h | Handles standard home appliance foam waste |

| Power Consumption | 15-20 kW | Energy-efficient design for cost savings |

| Dimensions | 2000x1500x1800 mm | Compact footprint for easy installation |

| Output Board Thickness | 10-50 mm | Adjustable based on customer requirements |

| Operating Temperature | 180-220°C | Optimized for efficient melting without degradation |

Clients benefit from reduced operational costs through automated processes, faster ROI from selling recycled boards, and enhanced sustainability credentials. The machine's safety features, such as overload protection and emergency stops, ensure a secure working environment. For businesses in packaging or recycling, this translates to scalable waste management and new revenue streams from foam byproducts.

With exports to key markets like North America, Southeast Asia, and Europe via ports including Qingdao and Shanghai, Henan Panqi Heavy Industry guarantees prompt global delivery and dedicated support. Our proven track record in serving diverse industries underscores this machine's reliability and efficiency. Invest in a solution that not only cuts waste but also drives profitability—contact us today for a consultation and discover how our expertise can elevate your recycling operations.

Frequently Asked Questions (FAQ)

-

What types of foam can this machine process?

It handles common foams like EPS and EPP from home appliance packaging, with options for other types customizable upon request. -

How energy-efficient is the machine?

Designed for low power consumption (15-20 kW), it uses advanced insulation to reduce energy costs by up to 30% compared to alternatives. -

What is the typical output quality of the extruded boards?

The extruded foam boards are uniform and dense, suitable for reuse in insulation or packaging, with thickness adjustable from 10-50 mm. -

Is operator training included?

Yes, comprehensive training is provided to ensure safe and efficient use, with manuals and optional on-site support. -

What maintenance is required?

Routine checks include cleaning the melting chamber and lubricating moving parts, typically needing minimal downtime every 3-6 months. -

Can the machine handle large-scale operations?

Absolutely, with a capacity of 100-200 kg/h, it's scalable for industrial use, and higher volumes can be accommodated with custom configurations. -

What warranty or support is offered?

We provide a standard 1-year warranty, with after-sales service available through our global network for parts and troubleshooting. -

How do I place an order?

Contact our sales team via email or phone for quotes and shipping details; we handle all logistics from ports like Ningbo or Guangzhou.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Foam Hot Melt Machine 5kg/h Output for Mattress ManufacturingNegotiableMOQ: 1 Set

-

Foam Hot Melt Recycling Equipment for Waste Foam & XPS Board ProcessingNegotiableMOQ: 1 Set

-

EPE Pelletizing Equipment for Furniture Cushion Filling Material ManufacturingNegotiableMOQ: 1 Set

-

EPE Foam Granulator for Automotive Soundproofing Material ProductionNegotiableMOQ: 1 Set

-

Pearl Cotton Granulator With Water Cooling System for Stable PerformanceNegotiableMOQ: 1 Set

-

Energy-Efficient Pearl Cotton Granulator With CE Standard Compliant DesignNegotiableMOQ: 1 Set

-

Stainless Steel EPE Pelletizing Machine With PLC Control SystemNegotiableMOQ: 1 Set

-

EPE Pelletizer With 1-Year Warranty and On-Site Technical SupportNegotiableMOQ: 1 Set

-

High-Speed EPE Pelletizer With 1200rpm Rotor for Continuous OperationNegotiableMOQ: 1 Set

-

Compact Pearl Cotton Pelletizer With 380V Power for Small-Scale RecyclingNegotiableMOQ: 1 Set