HUATE HGMS - Vertical Ring High Gradient Magnetic Separator (the 3rd Generation)

HUATE HGMS -

Vertical Ring High Gradient Magnetic Separator

(the 3rd generation)

Application:

It can be used in wet processing - 1.2 mm (- 200 mesh of 30 ~ 100%) red ores (hematite, limonite, siderite, etc.), manganese ore, ilmenite, chromite, tungsten ore and other kinds of weakly magnetic minerals, and non-metallic minerals, such as quartz, feldspar, nepheline ore, kaolin for removing impurity iron and purification.

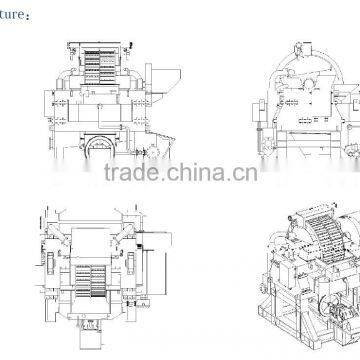

Structure:

Features:

No. 1: Armor

1) Avoiding coil magnetic flux leakage, preventing personal injury.

2) To avoid the leakage, the coil ends wrapped by electrical pure iron as iron armor, makes magnetic field uniformity increase more than 50%, magnetic field intensity increase more than 8%, separation effect is improved more than 20%

3) Protecting coil effectively, keep away external impact.

No. 2: Cooling system

1) Cooling system adopting wholly seald external circulation structure, rain-proof, dust-proof and corrosion-proof, it can used in harsh environment.

2) Adopting oil cooling circulation and air-cooling condenser, intelligent control, exciting coil in stationary temperature, magnetic field fluctuation in a small range (2%).

3) Adopting large flow disc transformer oil pump with fast cycle speed and strong heat exchange ability.

No. 3: Magnetic matrix part

Adopting abrasive-resistant permeability stainless steel as materials, unique structure and composite arrangement matrix

bars, with high gradient magnetic field.

No. 4: Magnetic Yoke

We choose the unique electrician pure iron which passed through high temperature treatment. Iron core is ladder laminated

structure.

No. 5: Pulsation

Drum membrane doing reciprocating motion driven by stroke box, repeatedly washing the materials absorbed on the surface of induction matrix, effectively eliminating the mechanical entrainment of non-magnetic materials, significantly improving the grade of magnetic concentrate.

No. 6: Control System

1) Adopting Schneider low voltage electrical elements and PLC, operation security, reliability and with long service life

2) Controlling part using advanced soft start function, avoiding the impact to coil and the disorder of coil, when suddenly energizing protecting coil effectively.

3) With advanced fault self-diagnosis system, you can choose remote control function.

4) When fault occurs, it can deliver the fault information to the technicists and provides accurate, timely technical support and safe guard for users.

5) Control cabinet shell is double-deck door structure, protective grade: IP55, dustproof,

waterproof,it can be used in harsh environment.

Standard export package in wooden cases, standard container, flat rack container or pack according to the requirements of customers.

Arrange the delivery around 45 days after receipt of the advanced payment.

Engineers are available to serve the machinery overseas.

As the largest and the most professional magnetic equipment manufacturer in China, we specialize in researching, developing and manufacturing various permanent and electric magnetic equipment and relative equipment. Welcome to visit our company.

We're seeking the co-operation in Europe. If you're interested, please feel free to contact me.

Lisa Lang

QQ No.: 410067206

Skype No.: lisa08041 at

Email: sales6 at

Mobile: +86-13793625720

Tel: +86-536-3391868

Fax: +86-536-3110552

Web:

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set