Low Consumption Cost High Frequency Induction Metal Forging Equipment

Specifications

induction metal forging equipment1. save electricity

2. high output

3. ISO 9001:2000

4. forging different work parts

Low consumption cost high frequency induction metal forging equipment

Features of induction metal forging equipment

1, small size, light weight, simple installation, easy to operate;

2, high efficiency, saving energy obviously,save 60% energy than traditional high frequency tube equipment, and save 20% energy than KGPS SCR IF induction heating power.

3, secure, reliable, non-million-volt high-pressure, very safe for the operator;

4, the frequency bandwidth to meet the different parts of the heating before forging, heat treatment, brazing, etc.;

5, a unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

Technical parameters of induction metal forging equipment

Model | WZP-120 |

Work power | 3 phase 380V+/-10%, 50-60HZ |

Input voltage | 320V-420V can be changed, depend on your country's electric power |

Input current | 6-200A |

Input power | 6-120KW(power adjusted stepless) |

Oscillation frequency | 10-50 KHZ |

Cooling water pressure | 0.3 MPA |

Size of geneartor: Transformer | 850*600*1330 780*540*520mm |

Weight of generator ; transformer | 131kgs; 89kgs |

Water cooling protection point | Below 50 degree celsius |

Accosseries: induction coils, foot switch,installing and operating instructions

Applications of induction metal forging equipment

1. Induction forging

1 The variety of hot-rolled twist drill.

2 standard parts, hot forging fasteners, such as high strength bolts, nuts and so on.

3 drill steel, tempering brazing, forging, extrusion heating.

Steel tableware induction forging

Standard parts forging

2. Induction hardening

1 The various hardware tools, hand tools, heat treatment. Such as pliers, wrenches, screwdrivers, hammers, axes and so on.

2 kinds of auto parts, motorcycle accessories high-frequency quenching. Such as: crankshaft, connecting rod, piston pin, crank pin, wheel, camshaft, valves, all kinds of rocker arm, rocker shaft; transmission of various gears, spline shafts, drive axle, a variety of small axes, a variety of fork and other high-frequency quenching.

3 power tools on the gears, shafts and other high-frequency quenching.

4 a variety of hydraulic components, pneumatic components of high frequency hardening heat treatment. Such as the piston plunger, rotor pump rotor on a variety of valves for the shaft, the gear pump gear, etc. quenching.

5 Heat treatment of metal parts. Such as the various gears, sprockets, all kinds of shafts, spline shafts, pins and other high-frequency quenching.

6 Machine tool industry guide, tools swallowtail quenching treatment.

Gear hardening

3. Induction brazing

1 welding diamond saw blade, carbide saw blade welding and diamond cutting tools, grinding tools, drilling welding.

2 carbide cutting tools for machining welding. Such as turning, milling cutter welding.

3 mining tools, welding, such as "one" bits, pillar gear drill bits, dovetail coal drill bits, drill rods riveting, all kinds of shearer, a variety of shearer, boring machine pick a variety of welding.

4 The welding of various wood working tools, such as various woodworking planer, milling, and welding a variety of woodworking drill.

We are in induction heating industry exhibition

Packing for induction metal forging equipment:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air/train/courier

Service process:

1. Online consult 2. Check drawings or pictures 3. Machine model(power and frequency ) recommendation 4. Make agreement 5. Production 6. debugging machine before sending goods 7. Delivery goods 8. Tracking goods 9. Provide documents help customer clearance customs 10, Tracking customer install and use machine cases

What’s your MOQ? | Any quantity of machine will be accepted. MOQ:1 Set |

Which place your factory is located? | We are located in Shenqiu County, Zhoukou city, Henan Province ,China |

How far from Beijing? I think it is more closer to Shanghai | Our factory is near both and Shanghai. We have office in Zhengzhou, we can pick up you at Zhengzhou CGO airport,and then to our factory via expressway about two hours. |

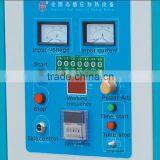

We need to see some more videos for production line and also pictures of your factory, water drawing and panel drawing | Well, we have many videos show our customer’s machine working scene(Various of applications: forging,hardening, brazing, shrink fitting, melting and hot coating etc. According to your work piece processing requirements,) send you the corresponding video link or send by email. 2. Yes, we can provide you factory pictures and machine water connection and control panel details. |

Do you have quality certifications? | Yes, we got the ISO9001:2000 International quality management system certification in August,2001, |

How do you packing the machines? | Standard export wooden cases(plywood) Usually every set machine will be used two wooden cases: one for packing induction heating generator, one for packing transformer. Inside will be filled with plastic foam for waterproof and shockproof |

More questions….? | Updating… |

Thanks for your reading ! Welcome to contact us !

Send Inquiry to This Supplier

You May Also Like

-

Multifunctional Twin-cylinder Baling Press for Aluminum CansUS$ 12500MOQ: 1 Unit

-

Automatic Semi Automatic Manual Fluidized Bed Dip Powder Coating Equipment Customizable for Refrigerator ShelvesUS$ 2000 - 40000MOQ: 1 Set

-

Replaceable Knives Wood Chipper Moveable Type Chips Ready for Compost or BoilersNegotiableMOQ: 1 Set

-

Hydraulic Baler for CansUS$ 3000MOQ: 1 Unit

-

Multifunctional Hydraulic Baler/hydraulic Briquetting Machine Manufacturing PlantUS$ 5500MOQ: 1 Unit

-

High Efficiency Energy Saving Fluidized Bed Dip Powder Coating Equipment Eco Friendly for Refrigerator ShelvesUS$ 2000 - 40000MOQ: 1 Set

-

High Adhesion Uniform Coating Fluidized Bed Dip Powder Coating Equipment Versatile for Refrigerator Shelves and Metal PartsUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Wood Chipper Price Tree Branches Reduce Debris by 80% With Precision BladesNegotiableMOQ: 1 Set