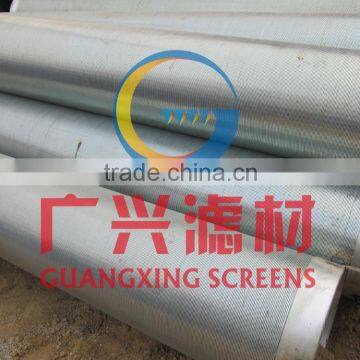

Well Screen Used in the Water Well

The Chinese best designed water wells use Guangxing Screen well screens. Today Guangxing use the best technology & the best material providing the best well screens for municipal, industrial, commercial, agricultural, domestic and environmental applications. Welcome your purchase, email and Skype both are OK.

Skype: gjmyxjj

mail: info08(at)haixing-filter(doc)com

info7526(at)guangxing-screens(doc)com

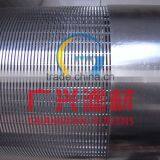

The continuous slot well screen is widely used in the world for water ,oil and gas wells,and the dominant screen type is used in the water well industry.Continuous slot well screen is made by winding cold rolled wire,approximately triangular in cross section,around a circular array of the longitudinal rods.The wire is attached to the rods by welding,producing rigid one piece units having high strength characteristics at minimum weights.

Slot size (mm): 0.10, 0.15, 0.2, 0.25, 0.30-6mm

Open area: up to 37%

Material: low carbon steel, low carbon galvanized steel (LCG) steel treated with plastic spraying, stainless steel (304,316L ect)

Lengths up to 6 meters

Diameter: 1.5", 2", 3", 4", 6", 8", 10", 12", 14",16",18"

End connection: plain beveled ends for butt welding or threaded.

Performances:

1.Production process continuity : V shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2.Low maintenance costs:Separation at the screens surface which can easily cleaned by scraping or back washing.

3.Maximum process output:Precise and continuous slot openings resulting in accurate separation without loss off media.

4.Low operational costs:Large open area with an effective flow .high yield and a low pressure drop

5.Long live:welded at each intersection creating a strong and durable screen

6.Reduced installation costs:Supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components

7.Chemical and thermal resistant:A variety of corrosion resistant stainless steel materials and many ecotic alloys suitable for high temperatures and pressures.

Send Inquiry to This Supplier

You May Also Like

-

Commercial-Grade Compost Machine for Agricultural and Horticultural Waste ManagementNegotiableMOQ: 1 Set

-

Water Bath SterilizerNegotiableMOQ: 1 Set

-

Urban Garbage Sorting Plant Solid Waste Sorting Line Bulky Msw Waste Separation MachineUS$ 23500 - 68500MOQ: 1 Set

-

Aquarium Filter Media/plastic Bio Carrier for Waste Water Treatment Plant/bio Pond Filter in Anox TankUS$ 1873.70 - 2637.05MOQ: 5 Cubic Meters

-

Heavy-Duty Vertical Dewatering Machine for High-Capacity Sludge ProcessingNegotiableMOQ: 1 Set

-

Replaceable Knives Wood Chipper Digital Maximize Efficiency for BiomassNegotiableMOQ: 1 Set

-

M931 Pex Plastic Water Ice LineNegotiableMOQ: 1

-

Nickel-Iron FoamNegotiableMOQ: 10 Square Miles

-

Refuse IncineratorUS$ 5900 - 25000MOQ: 1 Piece

-

Portable Foam Wall Chemical Oil Proof 750 Gallon Flexible Pvc Spill Containment BermNegotiableMOQ: 1