German Technology! QT10-15 Hydraulic and Automatic Cement Brick Making Machine Machines for House Construction

QT10-15 is our newest fully automatic hydraulic press block making machine, it's capacity is incomparable,reaching 15000/shift(400x200x200). It's pressure is super high,guaranteeing

the perfect density of blocks.with his convenient operation, local workers can manipulate it easily.

Advantages of QT10-15

1> PLC of Mitstibishi, Motor of Simens and Sensor of Omron, their using life is much longer

2>Electric box control all the operatiom,and indication light on board can point out the fautes

directly, save a lot of work and time for customers.

3>Becaue it is a full automatic machine, so many labor work can be saved

4>By chaning moulds, QT10-15 can make paver, solid and multi-holes bricks

5>Moulds get heat treatment and carbonization before installed on machine,more anti-wearing,

the life of mould can achieve 200000-300000 times.

6>For the motors, we use Siemens,ABB or other famous brands in china, life is much longer.

Main specification and technical parameters | |

Overall size | 3500x2220x2850mm |

Shaping cycle | 15-20 seconds |

Pallet size | 1300x900x30mm (bamboo) |

1300x900x30mm (plastic) | |

Vibration frequency | Max.4000 R/Min |

Electricity | 380V/220V/ (adjustable) |

Vibration force | 120KN |

Total weight | 13000 KGS |

1>Water,Cement,River sand, Crushed stone

2>Water,Cement,Slag

3>Water,Cement,Sand,Stone,Slag

Bricks and capacity

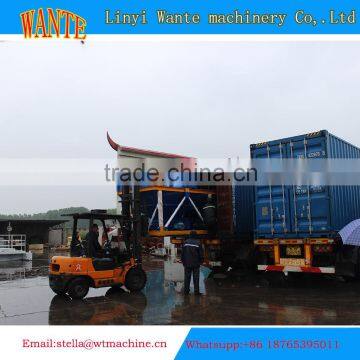

Delivery

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material,

capacity and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime,if you need, we can Make

inVitation card for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other.

Send Inquiry to This Supplier

You May Also Like

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Eco-Friendly Brick Making Machine Using Recycled Materials for Sustainable BuildingNegotiableMOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece