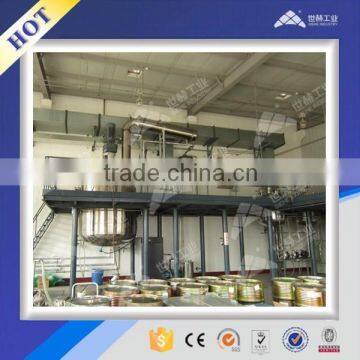

SZCT Unsaturated Polyester Resin Production Line

SZCT Unsaturated Polyester Resin Complete Production Line

Introduction

SZCT Resin Production Line is for producing products such as unsaturated polyester resin, phenolic resin, epoxy resin, ABS resin etc. It is also applicable for various emulsions. The complete production line normally consists of matching kettle, reaction kettle, vertical distillation column, vertical condenser, horizontal condenser, water storage, spill pot, pipeline and dilution vessels etc.

Features

SIEHE Company provides various resin reaction kettles. It can be customized in design and manufacture to meet different resin production requirements. It integrates raw materials storage, measuring, feeding, finished products transfer, storage and filling into one complete automatic closed production line, compact and of high working efficiency.

When the resin viscosity or the viscosity during reaction comes up to more than 300000 cps, it has especially high requirements for mixing equipment. SIEHE Company has rich experience in mixing high-viscous materials. Furthermore, SIEHE Company is familiar with resin (especially SMC, BMC resins) reaction and has rich application experience.

[Characteristics]: Viscosity ≤1,000,000 cps

[Capacity]:lab equipment-100,000T/year

[Application]Suitable for manufacturing of unsaturated polyester resins, phenolic resin, epoxy resin, alkyd resin, ABS resin,

etc as well as emulsion.

Capacity: lab scale to 100,000T/year.

Materials: SS304 SS316L SS321 Q235

Pressure level: normal pressure container, low-pressure container, middle-/low-pressure container.

Heating method: electrical heat, steam heat, hot water/hot oil recycle heat and far-infrared heating

Cooling method: jacket cooling, inside/outside tube jacket cooling

Surrounding requirement: ex-proof, non ex-proof

Others: droplet addition kettle, condenser, vacuum system, filling machine, etc are option and equipped according to process.

- Materials: SS304, SS316L, SS321, Q235

- Sealing: Packing Sealing, Mechanical Seal, Magnetic Sealing

- Agitator: Anchor type, Impeller type, Turbine Type, Propeller Type, Frame Type

- Supporting Base: Ground type, Platform Lug type

- Pressure Rating:Ⅰpressure container Ⅱ low pressure container, Ⅱmedium pressure container, normal pressure container

- Heating: electric heating, steam heating, hot water heating, heat transfer oil circulation heating, far-infrared heating etc.

- Cooling: jacket cooling, interior and exterior limpet coil cooling.

- Environment Requirements: of Non of

SIEHE Industry------expert on manufacturing and sales of liquid and powder equipment!

QQ: 2880860650

Skype: Polinder800

Tel:021-52913185-114

Phone: +86-18916519796

Send Inquiry to This Supplier

You May Also Like

-

Stacked Sludge DewateringNegotiableMOQ: 1 Set

-

Food Grade Liquid Mixing Tank Designed for Beverage and Dairy Production IndustriesNegotiableMOQ: 1 Unit

-

GYC Production Line of SoapNegotiableMOQ: 1

-

Multi Tube Vortex Mixer Laboratory MixerUS$ 753 - 753MOQ: 1 Piece

-

JHS2000 Mixer Double Movement Powder Mixer for Fine Powder, Superfine PowderUS$ 10,000 - 15,000MOQ: 1 Set

-

China Dry Mortar Zenamix Powder Mix Plant, Pigment Powder Mixing Machine for Making DetergentUS$ 800 - 1,500MOQ: 1 Set

-

Brightway Jet Mud Mixer of Solids Control SystemNegotiableMOQ: 1 Set

-

Fertilizer Manure Blender MixerUS$ 3,000 - 35,000MOQ: 1 Set

-

DJM Serie High Speed HomogenizerUS$ 1,000 - 5,000MOQ: 1 Unit

-

Industrial Horizontal Animal Ribbon Blender Dry Poultry Cattle Feed Mixer, Powder Mixer, Blender MixerUS$ 20,900 - 47,000MOQ: 1 Set