Rubber Gasket Insights & Buyer's Guide

Rubber gaskets make such a huge difference in so many overheads because they assure an airtight arrangement that will allow equipment and systems to function without a hitch. These multi-functional products perform the role of mechanical fixation, for example, they keep the vibrating parts together, prevent pressure loss due to fluid leakage, and provide protection against the ingress of foreign matter. Automotive and industrial applications all place a high dependence on rubber gaskets due to the attributes that they offer, as well as the property of stretch, which makes them flexible. This article is a detailed explanation of all the several designs of rubber gaskets, several useful and sector-based applications of the rubber gaskets, and lastly, key maintenance tips for the rubber gaskets so that they last as long as possible.

In the production of rubber gaskets, different types of materials are manipulated, each of which has specific advantages designed to fulfill the needs of particular applications. Below are several sorts of rubbers commonly used in making gaskets:

Silicone: Did you know that many silicone gaskets are preferred in high-temperature, extreme-temperature environments due to their resistance and elasticity?

Neoprene: Neoprene rubber gaskets perform different tasks at once and also last long. Due to these two properties, they have been used most widely in automobiles and industries for sealing.

Nitrile: Nitrile gaskets find eminent use in situations that call for resistance to chemicals, in particular, hydraulic machines which operate in environments with oils and fuels.

EPDM: EPDM gaskets are highly useful for applications that require exposure to the outdoors, as they possess weatherproof and Ozone immunity, which makes them non-perishable.

It is very important to ensure that the proper rubber gasket material is selected to allow the expected or desired mode of operation in terms of performance and even lifespan, among others. To determine which gasket is appropriate, one looks at the applicable temperature range, pressure levels, and, if necessary, chemical compatibility, among other things. For example, in hot gaseous/liquid environments, usually, silicone gaskets are opted for as there’s no likelihood of the gaskets breaking away after much heat. Likewise, in circumstances of certain chemical exposure, nitrile and Viton gaskets, respectively, have to be used because of their excellent chemical resistance. The better you comprehend the evolution of requirements, the easier it gets to choose the type of gasket material that does overtime, gives good seal service life by avoiding earlier gasket failures.

Learning About Gasket Substances

Catalog of Gasket Substances Made Out of Rubber

One of the critical aspects of providing fluid integrity in different applications is the incorporation of rubber gasket materials in a number of sectors. The different types of rubber materials that exist exhibit similar characteristics, as they are used appropriately under certain conditions.

Silicone rubber is well known for being very heat-proof and also very resilient; therefore, using it favors conditions of changing temperatures.

The Neoprene is very useful because it is neither flimsy nor easily eaten away by chemicals and has its great use both in cars and in the construction industry.

When it comes to chemical resistance, the most common of all rubbers used in parts internally submerged or in contact with oils, fuels, and hydraulic fluids is Nitrile rubber.

This highlights that EPDM rubber is known for its outstanding properties of withstanding ozone degradation and weathering. Therefore, it is widely incorporated in the manufacture of outdoor parts.

When we refer to certain materials employed in the production of gaskets, it is because the selection of suitable gaskets for every application is important to minimize leakages and reduce wear and tear of equipment in use.

The Various Rubber Gaskets

There are different kinds of rubber gaskets available in the market since various industries’ sealing requirements are different. Listed below are some of the most popular types:

O-rings: essentially, are circular and looped kind of gaskets whose use cuts across many areas such as automotive, pumping machines, etc. This is because they can cope with very high pressure without losing their flexibility.

Compressed sheet gaskets: These are mainly made of the more popular rubber gasket materials, either natural or synthetic in nature, and can provide a firm seal for high-pressure scenarios.

Custom gaskets: made to fill odd or non-standard shapes and take care of instrumentations with special requirements for proper sealing.

Materials: Rubber sheets are capable of being tailored to any requisite measurement and geometry, cut into a gasket for use in several sealing techniques.

The suitability of a specific variety of gasket relies on the application environment, service life, and chemical resistance, of course, enabling the correct implementation of the gasket in question.

Silicone as well as Neoprene rubber gaskets

One of the most popularly used types of gaskets is made of silicone and neoprene due to the various features that each type demonstrates. The fact that silicone gaskets are highly resistant to temperature fluctuations is well known. They do not disintegrate when subjected to high or low temperatures. As a result, they are ideal for sectors such as “aero-space” and automotive, where temperature extremes are part of normal working conditions. This also helps in constraining rough and rugged lip seals with ease. Compared to silicone gaskets, neoprene gaskets are preferred since they have the advantage of being strong enough despite their chemical structure, which reduces their need for a rubber gasket. Such gaskets are mostly used where oils, greases, and slight chemicals are present. This flexibility in the material allows it to be employed in apparatus, especially those in the cold, such as cars, refrigeration systems, and other machines. Such specific benefits of gaskets’ practicality of using either silicone or neoprene do exist, and their understanding can vastly increase the efficiency of the users in these hostile working conditions.

Applications of Rubber Gaskets Across Industries

Automotive Applications

In the car manufacturing sector, rubber gaskets are incredibly vital, ensuring the proper working of cars. These much-needed components are mostly applied in sealing engine and transmission units, among other systems in the car, thus preventing fluid leakage as well as keeping pressure at appropriate levels. Such properties of silicone and neoprene, resilience to high temperatures and aging, are greatly beneficial in engine environments with high temperatures and pressures, which are the main reasons why these are used in making gaskets. A rubber gasket called an o-ring is used in fluid-operated systems and pumps to prevent fluids from escaping and allow them to function properly. Because of their high resistance to the effects of chemicals, neoprene gaskets are used in applications that deal with oil and fuel, such as lines for fuel and seals for oil. The adaptability and dependability offered by rubber uplift the construction and servicing of automobiles by means of gaskets and seals, which is critical for the prolongation and perfection of a vehicle.

Aerospace Industry Uses

Demands from the aerospace industry are very high as structures of aircraft require working materials that can tolerate harsh atmospheric conditions, and that is why rubber gasket is proven to be one of the most demanding sub-systems of the aircraft, not the least system of an aircraft itself. Gaskets made of silicone, particularly, are preferred greatly because of their very high temperature toleration, wherein these materials stay sealed in largely high-temperature environments, examples being jet engines and passenger compartments. Gaskets of EPDM and nitrile materials also stay strong in terms of chemical invasion and ozone at high altitudes, making gaskets durable. In the aerospace industry, gaskets are typically improved on the case-specific components of an aircraft, and this ensures the perfect sealing of a component, which guarantees the safety of a system. Such gaskets are intended to withstand high pressures and movement, among other factors, and for this reason must be produced from materials that are very elastic and wear-resistant for quite a long period. In aerospace, the rubber gasket materials are enhanced and adapted for more difficult applications. This not only improves safety but also facilitates aviation technology.

Building and Construction Industry

Rubber gaskets, vast and unfathomable as their applications are, are some of the most common sealing solutions in the building and construction industry as well as plumbing. In terms of external environments, for instance, roofing and window sealing, such as EPDM gasketing, owing to its high weathering and ozone properties, is a popular choice. Whereas in plumbing, rubber gaskets are used in pipes and pipe fittings such that water does not leak out and also retains pressure. The use of Neoprene gaskets in these environments is common, and since they are not hard and score well in wearing out and tearing, they are also found favorable for frequent use and thermal variations of water. Therefore, rubber gaskets prove to be the most appropriate in such projects, especially in buildings where they improve the durability and safety of the structure, both residential and business-wise.

Benefits of Using Rubber Gaskets

Durability and Longevity

Here is one of the most commonly used advantages of rubber gaskets and that is the ability to outlast all other materials, making them essential for several industries. Materials such as silicone, neoprene, and EPDM, which are rubber-based, He uses words sophdatysiccsainolu opnsteonatis wile wring a perpectsocay, knwhw activities such as extremeextreme preshr durtion schkeneral wilesalslndions stablcod innctuiksa seal meajis aware aoinktilarges. Going into many different aspects of a subject, they are very good, even when exposed to heavy-duty and abrasive work, they are very durable. In case of gaskets, it is mostly abrasion, which is a problem that affects it; hence, problems like these, including using the product more than the manufacturer anticipated without affecting the product as much, come in. Gasket use calls for the choice of materials; it is worth noting that rubber gaskets such as nitrile and Viton give, thanks to their capability of enhancing chemical resistance and durability even in extreme chemical environments. Maintenance is reduced, and the equipment can be serviced over a longer interval, hence offering overall cost efficiency due to reduced equipment failure.

Flexibility and Reduction of Vibration

One unique advantage of the rubber gasket is the flexibility that it offers; the gasket permits the gasket to conform to uneven surfaces and still accomplish effective sealing in different conditions. Such flexibility is useful when components are prone to movement or expansion due to temperature changes. Ashes such as silicone gaskets are applied in installations where gas changes occur because they do not lose the ability to bend significantly at extreme temperatures. Rubber gaskets also have excellent vibration-damping properties, which are very important from the point of view of industrial as well as automotive applications. Materials such as neoprene and EPDM are elastomeric, which means that they can absorb and even dampen vibrations. This ability to dampen vibrations is pivotal because it aids in the machine’s operations and also helps in improving the machine’s longevity, owing to the fact that it limits the amount of any continuous vibration destruction.

Environmental Resistance

Elastic washers afford excellent protection from the environmental elements, hence they can be used in different outdoor as well as industrial settings. Formulations such as EPDM and Neoprene are meant to tolerate exposure to ozone, ultraviolet, and other harmful factors without losing the sealing advantage. Such resistance to attacks from the environment is what enables the rubber seals to remain functional through years of exposure to adverse weather conditions. In addition, there is the fact that there are particular rubbers that have high resistance to chemicals, for example, nitrile and Viton, and these are used in places where oil, fuel, or other such destructive products are accessible. Such environmental challenges not only make the service life of the rubber gasket longer but also guarantee the application against leakages and failure that may cause severe damage to the system. Hence, by selecting a suitable rubber gasket for the purpose, industrial companies can maximize the quality of the outcome and minimize the impact on the environment.

Frequently Asked Questions (FAQs)

How many varieties of rubber gaskets are manufactured?

The possibility of having rubber gaskets exists in several forms, ranging from pure rubber to artificial forms of believed caoutchouc kinds like Neoprene and Nitrile leather. In each of these cases, they have several properties they possess and thus different applications where they are better applied. For example, there is strong nitrile rubber in the system of petroleum, which cannot be appreciated in cases where petroleum exists. Whereas the skilled seamstress will take a passion in weaving, culinary, or sewing arts, most of the functions will lean towards needlework. They include silicone rubber, which is very stable even at very high temperatures, and therefore can be used in motor engines. However, in most cases, the selection of a certain gasket is made according to the particular demands that will make it functional and the environment in which it will be used.

Which is the best rubber gasket to be used under hydraulic clamps?

There are many considerations when selecting a rubber gasket for hydraulic applications, such as the type of fluid, pressure, and temperature ranges. Elastomers such as nitrile and fluorocarbon-based are used widely in hydraulic fluids because of their extreme resistance to chemical substances. Moreover, the rubber’s sealability characteristics against pressure can be improved or compromised based on the hardness and compression set of the rubber. It is equally important to evaluate the mating components and the compatibility with the rubber gasket material. It may also be worth seeking the advice of the supplier of rubber products in order to understand what is the most appropriate option for your hydraulic application.

Why are custom gaskets used in industries, and what benefits do they offer?

Industrial applications have particular needs, and gaskets are custom-made to conform to them so that they are suitable for the various mating surfaces. This means there is little chance of leaks or external elements, such as a contaminant, being introduced into the system. Moreover, it is possible to manufacture custom gaskets from superior quality materials that are both permanent and resistant to high temperatures or vibrations. Since they are customized, such gaskets find applicability in different types of machines and other equipment, thereby increasing the useful life of such components. With tailor-made options available, sectors manage to enhance their productivity and contain maintenance expenditure as well.

How far does a silicone rubber gasket stand up to the heat?

A rubber gasket made for use in the engine compartment has great significance in those cases where elastic sealing material has to work in high temperatures. Such materials are used, for example, in the automotive industry or heavy manufacturing, where extreme heat causes no expansion or degradation of the material. Apart from temperature, silicone gaskets are resistant to UV rays as well as to the impact of ozone, which increases their shelf life. Before choosing a silicone rubber gasket, the intended use and hardness, and, for effective use, the compression of the rubber gasket should also be checked. All these types of gaskets have multiple uses where they can be used where there is a need to insulate against temperature.

What is the role of a rubber in a vibration cutting machine?

Rubber gaskets are elements of great importance because they help reduce vibrations, which are created in the course of an operation by absorbing and dampening the vibration. However, the characteristics of rubber as an elastic material enable its extension and deformation, which serve to reduce the effect of the vibration on the adjacent components. Such dampening is crucial in the case of robust machinery since extreme vibrations lead to damage. More so, rubber gaskets help to improve the efficiency as well as the durability of machinery by minimizing mechanical and vibration-related problems. Getting the appropriate rubber gasket is very important and comes into play when the purpose is of importance to achieve the maximum damping.

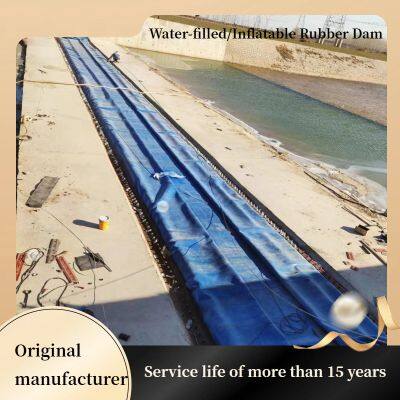

Environmentally Friendly Rubber Dam With Sealing Gaskets and Easy InstallationUS$ 290 - 300MOQ: 20 MetersMaterial: Other, EPDM Rubber with Polyester ReinforcementHeight Adjustment: Flexible 0.5-3m CustomizableInstallation: Anchor Bolts & Concrete FoundationCertifications: ISO9001, ISO9004, QS9000Hengshui Haogu Engineering Materials Co., Ltd.1 Yr

Environmentally Friendly Rubber Dam With Sealing Gaskets and Easy InstallationUS$ 290 - 300MOQ: 20 MetersMaterial: Other, EPDM Rubber with Polyester ReinforcementHeight Adjustment: Flexible 0.5-3m CustomizableInstallation: Anchor Bolts & Concrete FoundationCertifications: ISO9001, ISO9004, QS9000Hengshui Haogu Engineering Materials Co., Ltd.1 Yr Fridge Door Plastic Gasket PVC Frame RUBBER Freezer Durable Sealing Gasket Seal Strips Seal Strip PVC Compound GranulesUS$ 800.00 - 1000.00MOQ: 5 Tonscolor: Customized ColorShape: granulesTongxiang Small Boss Special Plastic Products Co.,Ltd.1 Yr

Fridge Door Plastic Gasket PVC Frame RUBBER Freezer Durable Sealing Gasket Seal Strips Seal Strip PVC Compound GranulesUS$ 800.00 - 1000.00MOQ: 5 Tonscolor: Customized ColorShape: granulesTongxiang Small Boss Special Plastic Products Co.,Ltd.1 Yr Rubber GasketsUS$ 0.6 - 0.6MOQ: 10000 MetersBrand Name: jufengPlace of Origin: ChinaModel Number: jufeng-414Qinghe Jufeng Rubber Seal Co., Ltd5 Yrs

Rubber GasketsUS$ 0.6 - 0.6MOQ: 10000 MetersBrand Name: jufengPlace of Origin: ChinaModel Number: jufeng-414Qinghe Jufeng Rubber Seal Co., Ltd5 Yrs Rubber GasketsNegotiableMOQ: 1000 MetersPlace of Origin: Hebei, ChinaBrand Name: shichangModel Number: TY016Hebei Tianyue Auto Parts Co., Ltd.5 Yrs

Rubber GasketsNegotiableMOQ: 1000 MetersPlace of Origin: Hebei, ChinaBrand Name: shichangModel Number: TY016Hebei Tianyue Auto Parts Co., Ltd.5 Yrs Rubber Gasket Cutting MachineNegotiableMOQ: 1 Cubic FootPlace of Origin: ChinaQingdao Judong Industry Co.,ltd5 Yrs

Rubber Gasket Cutting MachineNegotiableMOQ: 1 Cubic FootPlace of Origin: ChinaQingdao Judong Industry Co.,ltd5 Yrs Auto Parts---Rubber GasketNegotiableMOQ: 1 PolePlace of Origin: ChinaQingdao Shunlian Automotive Parts Manufacturing Co.,Ltd5 Yrs

Auto Parts---Rubber GasketNegotiableMOQ: 1 PolePlace of Origin: ChinaQingdao Shunlian Automotive Parts Manufacturing Co.,Ltd5 Yrs Vibrating Screen-Rubber GasketUS$ 15 - 60MOQ: 20 PiecesStandard or Nonstandard: NonstandardStyle: Mechanical SealMaterial: RubberPlace of Origin: Henan, ChinaXinxiang Gaofu Machinery Co., Ltd.5 Yrs

Vibrating Screen-Rubber GasketUS$ 15 - 60MOQ: 20 PiecesStandard or Nonstandard: NonstandardStyle: Mechanical SealMaterial: RubberPlace of Origin: Henan, ChinaXinxiang Gaofu Machinery Co., Ltd.5 Yrs Silicone Rubber GasketUS$ 0.05 - 0.5MOQ: 1000 PiecesPlace of Origin: Shandong, ChinaRizhao Lanshan Yongsheng Rubber & Plastic Co., Ltd.5 Yrs

Silicone Rubber GasketUS$ 0.05 - 0.5MOQ: 1000 PiecesPlace of Origin: Shandong, ChinaRizhao Lanshan Yongsheng Rubber & Plastic Co., Ltd.5 Yrs Rubber Gasket Cutting MachineUS$ 5.89 - 10.56MOQ: 20 PiecesPlace of Origin: Guangxi, ChinaBrand Name: LUKModel Number: LUK11291004Liuzhou Lian United Knives Co., Ltd.5 Yrs

Rubber Gasket Cutting MachineUS$ 5.89 - 10.56MOQ: 20 PiecesPlace of Origin: Guangxi, ChinaBrand Name: LUKModel Number: LUK11291004Liuzhou Lian United Knives Co., Ltd.5 Yrs EPDM Rubber GasketUS$ 4 - 6MOQ: 1000 KilogramsPlace of Origin: Zhejiang, ChinaBrand Name: PWSModel Number: 9.25.55602- 03Hangzhou Puwei Industry Co., Ltd.5 Yrs

EPDM Rubber GasketUS$ 4 - 6MOQ: 1000 KilogramsPlace of Origin: Zhejiang, ChinaBrand Name: PWSModel Number: 9.25.55602- 03Hangzhou Puwei Industry Co., Ltd.5 Yrs Newly Rubber GasketUS$ 0.01 - 0.1MOQ: 1000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: YHModel Number: OEMNingbo Beilun Yinghui Industrial Parts Co., Ltd.5 Yrs

Newly Rubber GasketUS$ 0.01 - 0.1MOQ: 1000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: YHModel Number: OEMNingbo Beilun Yinghui Industrial Parts Co., Ltd.5 Yrs Elastic Rubber GasketNegotiableMOQ: 100 PiecesPlace of Origin: Hebei, ChinaBrand Name: BenchengModel Number: BC-ERG-1000Tangshan Bencheng Science & Technology Co., Ltd.5 Yrs

Elastic Rubber GasketNegotiableMOQ: 100 PiecesPlace of Origin: Hebei, ChinaBrand Name: BenchengModel Number: BC-ERG-1000Tangshan Bencheng Science & Technology Co., Ltd.5 Yrs Customer Design Silicone Rubber GasketUS$ 0.01 - 2MOQ: 10000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: IDEALPARTModel Number: Customer Design Silicone Rubber GasketYuyao Ideal Auto Part Co., Ltd.5 Yrs

Customer Design Silicone Rubber GasketUS$ 0.01 - 2MOQ: 10000 PiecesPlace of Origin: Zhejiang, ChinaBrand Name: IDEALPARTModel Number: Customer Design Silicone Rubber GasketYuyao Ideal Auto Part Co., Ltd.5 Yrs Rubber Gasket Aerosol Valve With ActuatorUS$ 0.03 - 0.06MOQ: 100000 SetsMaterial: MetalMetal Type: TinplateUse: AerosolPlace of Origin: Hebei, ChinaYanshan Jinxing Aerosol Valve Manufacture Co., Ltd.5 Yrs

Rubber Gasket Aerosol Valve With ActuatorUS$ 0.03 - 0.06MOQ: 100000 SetsMaterial: MetalMetal Type: TinplateUse: AerosolPlace of Origin: Hebei, ChinaYanshan Jinxing Aerosol Valve Manufacture Co., Ltd.5 Yrs Flat Practical Customized Rubber GasketUS$ 0.1 - 5MOQ: 1 PiecePlace of Origin: Hebei, ChinaBrand Name: BaimiModel Number: customized rubber gasketMaterial: Other, Rubber, EPDM,Silicone,FKM,NBR,SBR,Sponge Rubber...Zhongde (Beijing) Machinery Equipment Co., Ltd.5 Yrs

Flat Practical Customized Rubber GasketUS$ 0.1 - 5MOQ: 1 PiecePlace of Origin: Hebei, ChinaBrand Name: BaimiModel Number: customized rubber gasketMaterial: Other, Rubber, EPDM,Silicone,FKM,NBR,SBR,Sponge Rubber...Zhongde (Beijing) Machinery Equipment Co., Ltd.5 Yrs Silicone Seals Silicone Rubber GasketUS$ 1 - 5MOQ: 200 KilogramsPlace of Origin: Guangdong, ChinaBrand Name: MIKANGWANGModel Number: rubber sealFoshan Nanhai Kangsu Decoration Material Co., Ltd.5 Yrs

Silicone Seals Silicone Rubber GasketUS$ 1 - 5MOQ: 200 KilogramsPlace of Origin: Guangdong, ChinaBrand Name: MIKANGWANGModel Number: rubber sealFoshan Nanhai Kangsu Decoration Material Co., Ltd.5 Yrs HOT SEAL STR Rear Engine Rubber Gasket Flat Rubber Gaskets Engine Left Rubber Gasket for LingyangUS$ 3 - 10MOQ: 50 PiecesType: Cylinder GasketSize: 20*6.8*10.8Car Make: STR/ HOWO/KINGKAN/GOLD PRINCEPlace of Origin: Hebei, ChinaXingtai Changshuo Auto Parts Co., Ltd.5 Yrs

HOT SEAL STR Rear Engine Rubber Gasket Flat Rubber Gaskets Engine Left Rubber Gasket for LingyangUS$ 3 - 10MOQ: 50 PiecesType: Cylinder GasketSize: 20*6.8*10.8Car Make: STR/ HOWO/KINGKAN/GOLD PRINCEPlace of Origin: Hebei, ChinaXingtai Changshuo Auto Parts Co., Ltd.5 Yrs Rubber Gasket Seal for Ozone Test Chamber DoorUS$ 5,500 - 8,500MOQ: 1 SetBrand Name: HongjinPlace of Origin: Guangdong, ChinaModel Number: HY-OZ-150Power: ElectronicHongjing Test Instrument Co., Ltd.5 Yrs

Rubber Gasket Seal for Ozone Test Chamber DoorUS$ 5,500 - 8,500MOQ: 1 SetBrand Name: HongjinPlace of Origin: Guangdong, ChinaModel Number: HY-OZ-150Power: ElectronicHongjing Test Instrument Co., Ltd.5 Yrs Rubber Gasket 36172-P0A-005 for HondaUS$ 5 - 9MOQ: 10 PiecesPlace of Origin: Guangdong, ChinaBrand Name: fengmingModel Number: 36172-P0A-005Guangzhou Fengming Auto Parts Co., Ltd.5 Yrs

Rubber Gasket 36172-P0A-005 for HondaUS$ 5 - 9MOQ: 10 PiecesPlace of Origin: Guangdong, ChinaBrand Name: fengmingModel Number: 36172-P0A-005Guangzhou Fengming Auto Parts Co., Ltd.5 Yrs Socket Rubbers Gasket for Slot Handrail TubeUS$ 1 - 8MOQ: 500 MetersBrand Name: JINXINModel Number: YK-935AUsage: Shelf BracketMaterial: Stainless SteelGuangzhou Jinxin Hardware Products Manufactory5 Yrs

Socket Rubbers Gasket for Slot Handrail TubeUS$ 1 - 8MOQ: 500 MetersBrand Name: JINXINModel Number: YK-935AUsage: Shelf BracketMaterial: Stainless SteelGuangzhou Jinxin Hardware Products Manufactory5 Yrs Purchasing Director placed an order for Non-asbestos Rubber Gasket2025-12-20 19:53:03

Purchasing Director placed an order for Non-asbestos Rubber Gasket2025-12-20 19:53:03 Operations Head placed an order for Auto Spare Parts Gasket kits Rubber ring Oil Seal 7135-70 7135-110 7135-682025-12-23 10:36:49

Operations Head placed an order for Auto Spare Parts Gasket kits Rubber ring Oil Seal 7135-70 7135-110 7135-682025-12-23 10:36:49 Sourcing Manager placed an order for Water tight rubber seal strip rubber gasket for solar panels2025-12-20 09:47:58

Sourcing Manager placed an order for Water tight rubber seal strip rubber gasket for solar panels2025-12-20 09:47:58 Lead Purchaser placed an order for Rubber Gasket Cutting Machine/Rubber Washer Cutting Machine2025-12-20 07:03:31

Lead Purchaser placed an order for Rubber Gasket Cutting Machine/Rubber Washer Cutting Machine2025-12-20 07:03:31 Purchasing Director verified certifications for D5010295777 Engine Dci11 rubber valve cover gasket2025-12-23 04:14:28

Purchasing Director verified certifications for D5010295777 Engine Dci11 rubber valve cover gasket2025-12-23 04:14:28 Procurement Lead requested specs for NBR camlock rubber gasket2025-12-18 17:06:39

Procurement Lead requested specs for NBR camlock rubber gasket2025-12-18 17:06:39 Best Sale Rubber Gasket Cutting MachineUS$ 2,000 - 4,999MOQ: 1 SetCondition: NewPlace of Origin: Henan, ChinaBrand Name: HENTOModel Number: HTO-XJ30Zhengzhou Hento Machinery Co., Ltd.5 Yrs

Best Sale Rubber Gasket Cutting MachineUS$ 2,000 - 4,999MOQ: 1 SetCondition: NewPlace of Origin: Henan, ChinaBrand Name: HENTOModel Number: HTO-XJ30Zhengzhou Hento Machinery Co., Ltd.5 Yrs Rubber Cylinder Gasket Rubber Gasket Set Cylinder Cover GasketUS$ 0.1 - 1.2MOQ: 50 PiecesChongqing Feilong Jiangli Auto Parts Co., Ltd.5 Yrs

Rubber Cylinder Gasket Rubber Gasket Set Cylinder Cover GasketUS$ 0.1 - 1.2MOQ: 50 PiecesChongqing Feilong Jiangli Auto Parts Co., Ltd.5 Yrs Engine Oil Stop Leak for Rubber Seal and Gasket Leakage Stop Rubber Gasket RepairUS$ 4.2 - 6.21MOQ: 680 PiecesPlace of Origin: Taiwan, ChinaBrand Name: WILITAModel Number: 00603Weight: 300 mlTai Jeou Polymer Chemical Co., Ltd.5 Yrs

Engine Oil Stop Leak for Rubber Seal and Gasket Leakage Stop Rubber Gasket RepairUS$ 4.2 - 6.21MOQ: 680 PiecesPlace of Origin: Taiwan, ChinaBrand Name: WILITAModel Number: 00603Weight: 300 mlTai Jeou Polymer Chemical Co., Ltd.5 Yrs Rubber Gasket for Stainless Stelel Screw for Black Painting Coated Zinc Die-coasting HingeUS$ 2.01 - 3.32MOQ: 500 PiecesPlace of Origin: Guangdong, ChinaBrand Name: YOANModel Number: CL219Shenzhen Sinwe Technology Co., Ltd.5 Yrs

Rubber Gasket for Stainless Stelel Screw for Black Painting Coated Zinc Die-coasting HingeUS$ 2.01 - 3.32MOQ: 500 PiecesPlace of Origin: Guangdong, ChinaBrand Name: YOANModel Number: CL219Shenzhen Sinwe Technology Co., Ltd.5 Yrs Customized Stainless Steel 316/304/303 Sheet Pipe Aluminum Die Engine Rubber Gasket Seals Kit Set With Turning Grinding PolishUS$ 1 - 100MOQ: 1 PieceCNC Machining or Not: CNC MachiningType: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Rapid Prototyping, Turning, Wire EDMMaterial Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel AlloysMicro Machining or Not: Micro MachiningDalian Hongsheng Machine Co., Ltd.5 Yrs

Customized Stainless Steel 316/304/303 Sheet Pipe Aluminum Die Engine Rubber Gasket Seals Kit Set With Turning Grinding PolishUS$ 1 - 100MOQ: 1 PieceCNC Machining or Not: CNC MachiningType: Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Rapid Prototyping, Turning, Wire EDMMaterial Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel AlloysMicro Machining or Not: Micro MachiningDalian Hongsheng Machine Co., Ltd.5 Yrs for SeaDoo 1503 Rubber Stopper GTX RXP-X RXT-X GTI GTR RX XP HX SPX SP BRP OEM MOUNT-RUBBER 270000631 Rubber Gasket 420950792US$ 0.26 - 5MOQ: 200 PiecesBrand Name: Gao ShengPlace of Origin: Hebei, ChinaWarranty: 1 YearsShijiazhuang Gaosheng Auto Parts Make Co., Ltd.5 Yrs

for SeaDoo 1503 Rubber Stopper GTX RXP-X RXT-X GTI GTR RX XP HX SPX SP BRP OEM MOUNT-RUBBER 270000631 Rubber Gasket 420950792US$ 0.26 - 5MOQ: 200 PiecesBrand Name: Gao ShengPlace of Origin: Hebei, ChinaWarranty: 1 YearsShijiazhuang Gaosheng Auto Parts Make Co., Ltd.5 Yrs Oil Cooler Rubber Gasket Kits Fit for Mini R55 R56 R57 R58 R59 R60 R61 N12 N14 N16 N18 Engine 11428643758 11428643747US$ 1 - 5MOQ: 10 PiecesBrand Name: GOGOPlace of Origin: Zhejiang, ChinaModel Number: GG-OS015Type: OtherSuzhou Qqqpet Electronic Technology Co., Ltd.5 Yrs

Oil Cooler Rubber Gasket Kits Fit for Mini R55 R56 R57 R58 R59 R60 R61 N12 N14 N16 N18 Engine 11428643758 11428643747US$ 1 - 5MOQ: 10 PiecesBrand Name: GOGOPlace of Origin: Zhejiang, ChinaModel Number: GG-OS015Type: OtherSuzhou Qqqpet Electronic Technology Co., Ltd.5 Yrs