Material Testing Insights & Buyer's Guide

Material testing is a major procedure that helps maintain the standard, security, and dependability of merchandise in businesses. Material properties ascertained through different testing techniques help organizations in making prudent choices concerning material usage and product development. This paper examines the various forms of material testing as well as provides the application of their use in sectors like construction, manufacturing, aerospace, and automotive industries.

If you are looking for more information about material testing - Wangtebei go here right away

Easy Apprehension Of Material Testing

Definition Of Material Testing

Materials testing is a study that checks the properties of a material and how it will perform in case it is exposed to certain circumstances, and whether it is appropriate for the given purpose. It deals with putting a piece of material through several tests, like tensile, compression, break, etc., using high-grade testing tools/machines called materials testers. The results of the tests provide details of the material, such as its strength, elasticity, and durability, which help in estimating the potential of any material in bearing various loads.

The Role Of Material Testing In Different Sectors

In different industries, it is important to show that the standards for the properties and performance of materials have been met through material testing. That is why, for example, in the construction industry, the need arises to check if the construction materials were able to withstand the harsh climatic conditions or not. In the field of aerospace and automotive industries, for instance, mechanical tests such as fatigue testing are also carried out in order to test the stability and aging conditions of materials. These involve methods such as the shear and creep tests, which allow one to estimate any probable failure of the material beforehand, other to maintain safety and adherence to standards.

Material Testing Methods in Detail

There are multiple ways of material testing applications based on the type of material in question and what properties of the material are to be evaluated. Testing for mechanical strength, for example, provides information about the material’s capability to withstand force, while testing for flexibility gives information about its ability to bend. Destructive testing often allows determining a material's condition without any damage, which is quite useful, especially for the components that are expensive or very critical for the operation of the tool. There are chemical, corroding test methods used to test responses of these materials when exposed to environmental factors, as well as dynamic tests and universal force measurement devices that help in testing the materials for effects present when used practically. The array of new types of material testing methods is quite wide in order to guarantee that the novel materials, as well as different shapes of products, will be durable as well as safe in use.

Key Types of Testing of Materials

Tensile Test: The Measurement of Strength and Ductility

Tensile testing is one of the most common tests for the mechanical properties of materials. This is intended to provide the tensile limits and the percentage elongation of a material. The sample is basically pulled under tension till the test sample breaks under a uniform rate of loading using a test apparatus. It provides useful information on the loading capacity of a given material after which it yields. A tensile test provides information on the stretching capacity of any material, which is of utmost importance to the study of any material testing done to meet tensile requirements, which in most cases is the ultimate strength in the case of several industries like construction and aerospace. These properties, once known, help engineers understand the failure of materials for the implicated degrees of strength or the working stress of a designed product, helping analyze its reliability.

Compression Test: Material Behavior Analysis

One more vital form of material testing is the compression test, which measures the capability of the materials to resist compressive loads. In contrast to the tensile test that stretches the material, the compression test involves pushing the test specimen together to assess its strength of crushing or buckling strength. This testing technique is important for any materials that are likely to experience compressive loads in practice, such as concrete in constructions or car metal fittings. The observation supports the detection of how strong a material is in compression for a given load so that the material can withstand the expected use without breaking.

Testing Resistance to Bending or Flexural Stress

Flexural testing is commonly known by many other names, but it is prominent for the fact that it ensures backward bending of materials up to a limit while testing. It is a performance testing experiment where a testing object is flexed to load for a considerable period to determine whether there is any deformation in it. The use of the beam bending test is mostly designed for structures that are elements that are subjected to a lot of torsion and bending movement, such as beams and suspensors. This allows the engineer to understand how the material will behave in terms of the expansion and contraction experienced, and ensures that it passes all the requirements of safety and performance. This range of material testing ensures that the materials do not break or collapse under such internal force, ensuring long-term quality of the products.

Non-Destructive Testing Methods

Non-Destructive Testing - An Introduction

Non-destructive testing (NDT) is a complex material testing procedure that examines a material, component, or system’s characteristics without harming it. It is common in scenarios where testing the object and maintaining its structure is not possible. NDT employs many methods, such as flaw detection, material characterization, and structural monitoring, to comprehend the material’s ability to support such conditions. It is valued in many industries such as aerospace, automotive, or construction, where high, yet non-destructive evaluation is required to, for instance, ensure compliance with regulatory safety requirements.

Overview of Common Non-Destructive Testing Methods

Equally important to the quality control of various manufactured or assembled products are some of the material testing methods which do not necessitate destruction to the test piece. For example, in ultrasonic testing, a high-frequency sound wave is directed towards a substance to check for its possible integrity. During the radiographic method of testing, the performance and condition of such components are evaluated through an X-ray or a gamma ray. Another type of inspection is by performing magnetization of the object and then spraying it with a special solution. The NDT resulted in producing useful information on the state of the material as to how it can be utilized for certain operating conditions without any failure taking place.

Uses of Nondestructive Testing

In order to understand the importance of material testing in industries, it is important to understand what non-destructive testing is. In the inspection of the aerospace industry, NDT is most important in the inspection of every type of structural component of an aircraft to avoid loss of the aircraft during operation. Non-Destructive Testing also extends to construction, which only evaluates how the structure is likely to hold up and be able to be used safely within the given span. In the automobile industry, NDT plays a role in determining the reliability and efficiency of parts in their ability to withstand dynamic forces. By utilizing NDT techniques, industries are capable of inspecting without causing damage to the materials being inspected, enabling them to maintain very high levels of safety and better performance of products without the need for destructive tests – hence the tested materials are still preserved for use in their respective functions.

Material Testing Devices and Techniques

Varieties of Material Testing Equipment

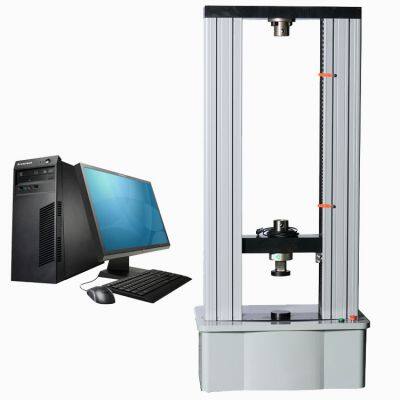

Machine tools that are designed for material testing are various and indispensable in this area. Material samples can be subjected to numerous tests so that specific properties are evaluated, and in such cases, the above-mentioned apparatus is used. For example, a tensile testing apparatus is used to determine a material’s tensile strength by pulling a sample until it breaks apart. The compression test apparatus helps study material characteristics through the practical application of compressive loads on the materials. Universal apparatus is used for numerous purposes, including tensile and compression tests. Apart from this, these apparatuses also ensure accurate test results, which then allow engineers to analyze the materials more effectively. However, the correct test equipment is selected based on the way that the test procedures are conducted and the material properties that need to be tested.

Advances in Testing Instruments and Methods

The areas of material testing have also very much improved due to the test equipment that has become available in recent years as a result of new technologies, than it was just a few years ago. These include designing high-resolution digital cameras and the utilisation of automatic testing, which aims at improving the accuracy of the test results. In the presence of more sophisticated sensors and data analysis, it makes it possible to track and examination of the characteristic features of a material while testing is just commencing. They appear to enhance traditional testing device use by offering engineers opportunities to proceed with more detailed analysis and a better understanding of how the material will perform. As a result, such improvements ensure that the novel materials created can abide by the rigorous quality and safety measures that modern design imposes.

AI and the Role of Automation in Material Testing.

There is a massive advancement in the material testing industry on account of the introduction of artificial intelligence and automation. Using artificial intelligence enables systems to study a mountain of test data and figure out and suspect how a material will react in different circumstances. The testing process is automated, leading to the reduction of errors by humans and the amount of work that needs to be done manually. As a result of AI and automation, industries are able to undertake testing on a larger scale while ensuring consistency, which helps determine that materials conform to quality specifications and hastens the product development process. This helps develop products with the reasons of aerospace, automotive, and construction markets.

Industrial Applications of Material Testing

Material Testing in the Building Industry

In the building industry, material testing is considered to be very important since it assists in determining the ability of building materials to resist the effects of weather changes. This industry has a number of material testing methods, such as tensile test methods and compression test methods, which are very vital when it comes to materials properties testing, and in particular tensile strength and compressive strength. Such tests facilitate understanding of the behavior of the different materials when placed under certain loadings and states, thus ensuring the buildings are stable. It also allows engineers to control the ultimate FAILURE of the material and improves public safety by preventing many accidents during the building’s service life.

Material Testing in the Industrial Sector

The discipline of material testing has always been an integral part of the manufacturing sector, as it aims at maintaining the quality and reliability of the end product. Industry-specific mechanical tests, such as tensile and bend tests, are also conducted to ascertain whether the material will satisfy the processing stage. These machines are used to determine if they are strong enough to survive the production process and perform the intended function of the product. Conventional non-destructive tests that include ultrasonic and radiographic testing are used to identify internal flaws in the materials. By conducting these tests, it is clear that manufacturers have been able to ensure that their products are designed according to the safety and performance requirements, hence satisfying the customers.

Material Testing in Aerospace and Automotive Industries

High-performance planes and cars require material testing to secure their parts from possible hazards or failure in operation. These industries carry out fatigue or dynamic tests to determine the behavior of the material when it is subjected to continuous loading or severe weather conditions. Many problems associated with materials that may cause severe damage are determined by material testing. Tensile properties, such as tensile strength or hardness, are tested for any material specimen of interest, via sophisticated instrumentation and test methods, including the all-purpose machine. Such stringent tests on the materials used in an airplane or car help them to withstand the roughening environment.

Ensuring Reliability Through Material Testing

Quality Control and Regulatory Compliance

Material testing forms a crucial element in quality control procedures. This is to guarantee the materials fulfill the expected regulatory requirements, which most sectors demand. Test results, such as those from the application of tensile and hardness tests, among others, seek to depict the characteristics of such materials, thereby showing their application areas. Their understandings comply with various industry standards and reduce the need for returns and avoid product failures. This defensive type of quality management is beneficial in upholding the reputation of the business, backed by a sustained customer orientation and commitment to delivering excellent products.

Longevity and Safety of Materials

Material testing is essential when it comes to product design since most products or devices involve or are made of materials, and analysis shows that most of the materials applied in design and construction are relevant to the lifetime span of use. Development of design advancements, such as creep or corrosion tests, enables designers to foresee the applicability of materials in given surroundings and climate. Such tests are necessary for the purpose of evaluating the working life of materials being utilized and predicting failure points of the structure. When a given structure is subjected to comprehensive tests, industries are assured of the safety of the materials in the course of use, location-wise, which enhances the design longevity, mitigating any risks of accidents. Regarding material sustainability, this alignment of goals is helpful for both the consumers and the environment.

Choosing the Right Material for Applications

For specific applications, material testing plays an important role in the determination of the most suitable materials. Different types of tests, for example, shear tests or flexural tests, are used to identify the physical properties of a given material. Therefore, different materials can be analyzed to know their suitability for a given purpose. This exercise assures the user that selected items are able to handle exposed statics as well as other environmental factors, for example, heat or moisture. This type of evaluation of materials is significant for the improvement or generation of any product in such a way that a strategy for the construction and placement of materials will achieve maximum effectiveness of the product. Material appropriateness depends greatly on how well the contents are selected, and the lack of errors in choosing the materials bodes well for the final products’ realization.

Frequently Asked Questions (FAQs)

Why is material testing important?

An understanding of the reasons why material testing is so essential is necessary because someone creates a material with the necessary standards of performance and safety. Various testing methods are employed to determine material properties like strength, endurance, and resistance to a particular environment. This process helps choose the right material that is suitable for the application of a particular material and its design, which in turn is an important factor in achieving and maintaining a certain level of quality and reliability of the product. Also, material testing helps to avoid material failure, and the associated threats of using deficient materials are reduced. The procedures to ensure that testing procedures are conducted correctly and testing results are valid are established by the American Society for Testing and Materials and other such organizations.

What are the different types of material testing?

Multiple kinds of material testing techniques have been developed and used for purposes of different evaluations of material properties. The most common of such techniques are tensile, compression, and bend tests because each of them performs the evaluation of some particular aspect of a material. Another important technique is non-destructive testing, in which the material is examined without being destroyed. Various mechanical evaluation methods, including methods of impact and fatigue tests, are performed, which are essential for the characterization of the material. All these tests make it possible for the engineers to select the most appropriate material for the given project.

What is a tensile test, and how is it performed?

A tension test can be defined as a primary test when it comes to material testing, as it quantifies a given material's sensitivity to tensile forces. The test is conducted using an instrument known as a tensile tester or a universal tester, in which a piece of material is subjected to a tensile load until a fracture occurs within it. The purpose of the test is to quantify attributes of the material, such as the ultimate tensile strength, percentage elongation, and modulus of elasticity. The results of the analysis can quite easily be interpreted to work out the tensile behavior of the material and further complete an evaluation of the applications of material testing. The information generated by tensile testing is useful in making sure that the materials are capable of handling applications in the field.

How does a compression test work?

A compression test evaluates a material’s capacity to bear axial external compressive loads. This is done by placing a sample in a test machine, which increases the compressive force applied to the sample until either deformation or failure occurs. Typical properties that are often assessed using this test include, but are not limited to: the compressive strength, the yield point of the material, and many others. This need to carry out material testing on construction and other material products is very crucial as it averts structural failure due to excess loading. A structural engineer can make use of the standard methods of material testing in evaluating the structural behavior of materials under stress.

What is non-destructive testing, and why is it used?

Non-destructive analysis (NDA, Non-destructive Testing, or NDT) involves the employment of methodologies of material testing that do not destroy the sample. This includes such techniques as ultrasound, X-rays, and visual testing with the use of a magnifying glass. NDT is utilized in many structural engineering and construction industries, including the airline and power generation industries, where, in the event of a material failure, the outcome will be extremely severe. Further, these testing techniques help the engineers to identify the imperfections/defects in the material, which avoids any danger due to using the materials. This good practice saves time, effort, and resources and increases trust in the materials in use.

How do material testing machines contribute to quality assurance?

In order to perform rapid characterisation of material properties, material testing machines appear to be an important set of equipment. Such machines may suit a vast array of testing requirements, e.g., tension, compression, bending, and others, which basically provide testing consistency. Modern technology, such as universal testing machines, enhances manufacturers’ ability to guarantee the achievement of materials specifications and tolerances. This, in turn, is a major factor upon which the control of quality is based, and the elimination of contributory factors that could cause material collapse in the end product is solely dependent. In conclusion, the application of material testing machines is a great way of assuring quality in different institutions.

Universal Material Testing Machine With High QualityUS$ 3000 - 10000MOQ: 1 SetJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr

Universal Material Testing Machine With High QualityUS$ 3000 - 10000MOQ: 1 SetJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr SCAIR 20HP 1.2MPa Oil-Free Compressor for Material Testing Machines & Research HydraulicsNegotiableMOQ: 1 UnitMaterial: Carbon SteelWarranty: one yearDrive Mode: ElectricLubrication Style: Oil-lessDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs

SCAIR 20HP 1.2MPa Oil-Free Compressor for Material Testing Machines & Research HydraulicsNegotiableMOQ: 1 UnitMaterial: Carbon SteelWarranty: one yearDrive Mode: ElectricLubrication Style: Oil-lessDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs Qatar LDPE MG70 Cracking Tube Special Material Nucleic Acid Test Box Raw Material Soluble 70 PolyethyleneUS$ 1210 - 1250MOQ: 10 TonsBrand Name: LotrènePlace of Origin: ChinaModel Number: MG70Suzhou Yifuhui New Material Co., Ltd.3 Yrs

Qatar LDPE MG70 Cracking Tube Special Material Nucleic Acid Test Box Raw Material Soluble 70 PolyethyleneUS$ 1210 - 1250MOQ: 10 TonsBrand Name: LotrènePlace of Origin: ChinaModel Number: MG70Suzhou Yifuhui New Material Co., Ltd.3 Yrs Water Blocking Airbag Natural Rubber Material Sewer Pipe Drainage Plugging Leak Closed Water Test Plugging AirbagNegotiableMOQ: 1 ComboMaterial: Composite RubberCertification: ISO9001Shape: CylindricalFunction: Closure TypeHengshui Haogu Engineering Materials Co., Ltd.1 Yr

Water Blocking Airbag Natural Rubber Material Sewer Pipe Drainage Plugging Leak Closed Water Test Plugging AirbagNegotiableMOQ: 1 ComboMaterial: Composite RubberCertification: ISO9001Shape: CylindricalFunction: Closure TypeHengshui Haogu Engineering Materials Co., Ltd.1 Yr API598 Tested ANSI Hard Seal Cast Iron Gate Valve for High-Pressure Environments, Robust Cast Iron Material DesignNegotiableMOQ: 1 PieceMaterial: Cast IronApplication: Other, Industrial Fluid Control SystemsValve Type: Gate ValveSeal Type: Hard SealChengxin Valve Co., Ltd.1 Yr

API598 Tested ANSI Hard Seal Cast Iron Gate Valve for High-Pressure Environments, Robust Cast Iron Material DesignNegotiableMOQ: 1 PieceMaterial: Cast IronApplication: Other, Industrial Fluid Control SystemsValve Type: Gate ValveSeal Type: Hard SealChengxin Valve Co., Ltd.1 Yr Seamless PED Duplex Stainless Steel Sch80s PE Be Building Material ASTM A790 Rust-Proof Honed Tube Hydraulic Test for Boiler /MarineUS$ 800 - 1100MOQ: 1 TonType: SeamlessSurface Treatment: OtherUsage: Pipeline Transport, Boiler Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Special PurposeMaterial: Stainless steelZhongzheng Stainless Steel Co., Ltd.1 Yr

Seamless PED Duplex Stainless Steel Sch80s PE Be Building Material ASTM A790 Rust-Proof Honed Tube Hydraulic Test for Boiler /MarineUS$ 800 - 1100MOQ: 1 TonType: SeamlessSurface Treatment: OtherUsage: Pipeline Transport, Boiler Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Special PurposeMaterial: Stainless steelZhongzheng Stainless Steel Co., Ltd.1 Yr Universal Materials Testing MachineUS$ 8,500 - 42,000MOQ: 1 SetBrand Name: HONGJINPlace of Origin: ChinaModel Number: HJ-D4Power: HydraulicHongjing Test Instrument Co., Ltd.5 Yrs

Universal Materials Testing MachineUS$ 8,500 - 42,000MOQ: 1 SetBrand Name: HONGJINPlace of Origin: ChinaModel Number: HJ-D4Power: HydraulicHongjing Test Instrument Co., Ltd.5 Yrs Material Testing Laboratory EquipmentsUS$ 4,000 - 7,000MOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: AUTOSTRONGModel Number: AUTO5105Power: ElectronicShenzhen Autostrong Instrument Co., Ltd.5 Yrs

Material Testing Laboratory EquipmentsUS$ 4,000 - 7,000MOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: AUTOSTRONGModel Number: AUTO5105Power: ElectronicShenzhen Autostrong Instrument Co., Ltd.5 Yrs IEC61588 Mandrel Test Device for Insulation Material TestNegotiableMOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: cxModel Number: CX-M01Usage: Other, Insulation Material testShenzhen Chuangxin Instruments Co., Ltd.5 Yrs

IEC61588 Mandrel Test Device for Insulation Material TestNegotiableMOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: cxModel Number: CX-M01Usage: Other, Insulation Material testShenzhen Chuangxin Instruments Co., Ltd.5 Yrs Professional Material Testing Lab Manufacturer ProducerUS$ 500 - 800MOQ: 1 SetMaterial: MetalMetal Type: IronSize: Lx1500X850Place of Origin: Fujian, ChinaXiamen Yixu Laboratory Equipment Co., Ltd.5 Yrs

Professional Material Testing Lab Manufacturer ProducerUS$ 500 - 800MOQ: 1 SetMaterial: MetalMetal Type: IronSize: Lx1500X850Place of Origin: Fujian, ChinaXiamen Yixu Laboratory Equipment Co., Ltd.5 Yrs Liyi Universal Material Testing Machine Yarn Tensile Strength Test EquipmentUS$ 3,980 - 6,980MOQ: 1 SetBrand Name: LIYIPlace of Origin: Guangdong, ChinaPower: ElectronicDongguan Liyi Environmental Technology Co., Ltd.5 Yrs

Liyi Universal Material Testing Machine Yarn Tensile Strength Test EquipmentUS$ 3,980 - 6,980MOQ: 1 SetBrand Name: LIYIPlace of Origin: Guangdong, ChinaPower: ElectronicDongguan Liyi Environmental Technology Co., Ltd.5 Yrs Custom Climatic Test Chamber for Reliability Test Stainless Steel MaterialUS$ 13,500 - 13,500MOQ: 1 UnitBrand Name: MENTEKPlace of Origin: ChinaModel Number: MHP-1300-CAPower: ElectronicBiaojin Packaging Equipment Co., Ltd.5 Yrs

Custom Climatic Test Chamber for Reliability Test Stainless Steel MaterialUS$ 13,500 - 13,500MOQ: 1 UnitBrand Name: MENTEKPlace of Origin: ChinaModel Number: MHP-1300-CAPower: ElectronicBiaojin Packaging Equipment Co., Ltd.5 Yrs Water Vapor Permeability Test Machine Permeation Testing Machine for Packaging MaterialUS$ 5.00 - 15.00MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: W 301Power: ElectronicThickness Tester Co., Ltd5 Yrs

Water Vapor Permeability Test Machine Permeation Testing Machine for Packaging MaterialUS$ 5.00 - 15.00MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: W 301Power: ElectronicThickness Tester Co., Ltd5 Yrs Glass PVB Film Test Instruments Steel MaterialsUS$ 50 - 500MOQ: 10 SetsPlace of Origin: Hebei, ChinaPower: OtherUsage: Bending Testing MachineQinhuangdao Yuanchen Hardware Co., Ltd.5 Yrs

Glass PVB Film Test Instruments Steel MaterialsUS$ 50 - 500MOQ: 10 SetsPlace of Origin: Hebei, ChinaPower: OtherUsage: Bending Testing MachineQinhuangdao Yuanchen Hardware Co., Ltd.5 Yrs Graduated Cylinder on Test Bench, With Material: Glass,45mlNegotiableMOQ: 10 PiecesType: Engine AnalyzerCertification: CE/ISO certificateTaian Haiyu Machinery Co., Ltd.5 Yrs

Graduated Cylinder on Test Bench, With Material: Glass,45mlNegotiableMOQ: 10 PiecesType: Engine AnalyzerCertification: CE/ISO certificateTaian Haiyu Machinery Co., Ltd.5 Yrs Laboratory Wire Mesh Test Sieve With Stainless Steel MaterialUS$ 900 - 1,000MOQ: 1 SetPlace of Origin: Henan, ChinaBrand Name: HongyuanModel Number: BSJ-200Power: Other, 370WXinxiang Hongyuan Vibration Equipment Co., Ltd.5 Yrs

Laboratory Wire Mesh Test Sieve With Stainless Steel MaterialUS$ 900 - 1,000MOQ: 1 SetPlace of Origin: Henan, ChinaBrand Name: HongyuanModel Number: BSJ-200Power: Other, 370WXinxiang Hongyuan Vibration Equipment Co., Ltd.5 Yrs Cotton Material and Disposable Style Free Sample Product to TestUS$ 0.018 - 0.035MOQ: 200000 PiecesType: Ultra ThinMaterial: CottonShape: WingedFeature: BreathableQuanzhou Focus Sanitary Products Co., Ltd.5 Yrs

Cotton Material and Disposable Style Free Sample Product to TestUS$ 0.018 - 0.035MOQ: 200000 PiecesType: Ultra ThinMaterial: CottonShape: WingedFeature: BreathableQuanzhou Focus Sanitary Products Co., Ltd.5 Yrs ISO Standard Rohs Tested Electrical Contact Material Bimetal Composite StripsUS$ 35 - 399MOQ: 50 KilogramsPlace of Origin: Guangdong, ChinaBrand Name: INTModel Number: INS171Dongguan INT Metal Products Factory5 Yrs

ISO Standard Rohs Tested Electrical Contact Material Bimetal Composite StripsUS$ 35 - 399MOQ: 50 KilogramsPlace of Origin: Guangdong, ChinaBrand Name: INTModel Number: INS171Dongguan INT Metal Products Factory5 Yrs BV SGS Test 4x8 Galvanized Corrugated Steel Sheet for Household MaterialUS$ 600 - 1,000MOQ: 1 TonStandard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCCThickness: 0.15-3.0mmPlace of Origin: Tianjin, ChinaTianjin TEDA YADA Steel Co., Ltd.5 Yrs

BV SGS Test 4x8 Galvanized Corrugated Steel Sheet for Household MaterialUS$ 600 - 1,000MOQ: 1 TonStandard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCCThickness: 0.15-3.0mmPlace of Origin: Tianjin, ChinaTianjin TEDA YADA Steel Co., Ltd.5 Yrs HT-225 Whole Sale Testing Equipment for Construction MaterialsUS$ 95 - 120MOQ: 10 UnitsPlace of Origin: Tianjin, ChinaBrand Name: MEModel Number: HT-225Power: ElectronicL&T Mechanical & Electrical Equipment Co., Ltd.5 Yrs

HT-225 Whole Sale Testing Equipment for Construction MaterialsUS$ 95 - 120MOQ: 10 UnitsPlace of Origin: Tianjin, ChinaBrand Name: MEModel Number: HT-225Power: ElectronicL&T Mechanical & Electrical Equipment Co., Ltd.5 Yrs Winner 2005B Laser Particle Size Analyzer for Micron Materials Size TestUS$ 1 - 2MOQ: 1 SetPlace of Origin: Shandong, ChinaBrand Name: WinnerModel Number: Winner 2005BJinan Winner Particle Instruments Co., Ltd.5 Yrs

Winner 2005B Laser Particle Size Analyzer for Micron Materials Size TestUS$ 1 - 2MOQ: 1 SetPlace of Origin: Shandong, ChinaBrand Name: WinnerModel Number: Winner 2005BJinan Winner Particle Instruments Co., Ltd.5 Yrs Electrical Power Single Universal Material Switch Cabinet Test Bench Transformer Test BenchUS$ 5,000 - 140,000MOQ: 1 SetBrand Name: HuaZhengPlace of Origin: Hebei, ChinaModel Number: HZPower: ElectronicHuazheng Electric Manufacturing (baoding) Co., Ltd.5 Yrs

Electrical Power Single Universal Material Switch Cabinet Test Bench Transformer Test BenchUS$ 5,000 - 140,000MOQ: 1 SetBrand Name: HuaZhengPlace of Origin: Hebei, ChinaModel Number: HZPower: ElectronicHuazheng Electric Manufacturing (baoding) Co., Ltd.5 Yrs Particulate Filtration Efficiency Tester ASTM F2299 PP 99BFE Material Meltblown Nonwoven Fabric Testing MachineUS$ 69,230 - 75,000MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: GB-KF30010Power: ElectronicGuangzhou Biaoji Packaging Equipment Co., Ltd.5 Yrs

Particulate Filtration Efficiency Tester ASTM F2299 PP 99BFE Material Meltblown Nonwoven Fabric Testing MachineUS$ 69,230 - 75,000MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: GB-KF30010Power: ElectronicGuangzhou Biaoji Packaging Equipment Co., Ltd.5 Yrs High Quality, 304 Material,Diameter 200mm/ 300mm, Stainless Steel Standard Test Sieve for Soil, Cement Fine AggregateUS$ 450 - 2,000MOQ: 1 SetPlace of Origin: Hainan, ChinaBrand Name: XianchenModel Number: XC Test sievePower: ElectronicXinxiang Xianchen Vibration Machinery Co., Ltd.5 Yrs

High Quality, 304 Material,Diameter 200mm/ 300mm, Stainless Steel Standard Test Sieve for Soil, Cement Fine AggregateUS$ 450 - 2,000MOQ: 1 SetPlace of Origin: Hainan, ChinaBrand Name: XianchenModel Number: XC Test sievePower: ElectronicXinxiang Xianchen Vibration Machinery Co., Ltd.5 Yrs High Quality and Safe Material Lab Fume Hood for Chemical/biology/Physical/medical Laboratory TestingUS$ 900 - 2,500MOQ: 1 UnitMaterial: PlasticSize: 1200/1500/1800*800*1250mm, 1200/1500/1800*800*2350mmPlace of Origin: Jiangsu, ChinaYifeng Clean Technology Jiang Su Shares Co., Ltd.5 Yrs

High Quality and Safe Material Lab Fume Hood for Chemical/biology/Physical/medical Laboratory TestingUS$ 900 - 2,500MOQ: 1 UnitMaterial: PlasticSize: 1200/1500/1800*800*1250mm, 1200/1500/1800*800*2350mmPlace of Origin: Jiangsu, ChinaYifeng Clean Technology Jiang Su Shares Co., Ltd.5 Yrs Business Owner is sourcing CE Certified Tensile Testing Machine Cloth Tensile Testing Machine Universal Material Test Machine2025-12-10 23:19:04

Business Owner is sourcing CE Certified Tensile Testing Machine Cloth Tensile Testing Machine Universal Material Test Machine2025-12-10 23:19:04 Buyer requested a quote for 45 Degree Automatic Flammability Tester Fabric Burning Test Meet ASTMD123015 hours ago

Buyer requested a quote for 45 Degree Automatic Flammability Tester Fabric Burning Test Meet ASTMD123015 hours ago Procurement Lead negotiating terms for Electro-hydraulic servo material testing equipment, material testing laboratory equipments2025-12-12 16:15:42

Procurement Lead negotiating terms for Electro-hydraulic servo material testing equipment, material testing laboratory equipments2025-12-12 16:15:42 Procurement Lead submitted an RFQ for German non - metallic materials testing machineimport qingdao customs clearance2025-12-10 18:52:13

Procurement Lead submitted an RFQ for German non - metallic materials testing machineimport qingdao customs clearance2025-12-10 18:52:13 Purchasing Director placed an order for Hydraulic Material Testing2025-12-13 22:16:31

Purchasing Director placed an order for Hydraulic Material Testing2025-12-13 22:16:31 Sourcing Manager inquired about Cone Calorimeter Gbt16172 ASTM E1354 ISO 56602025-12-11 07:53:30

Sourcing Manager inquired about Cone Calorimeter Gbt16172 ASTM E1354 ISO 56602025-12-11 07:53:30 Operations Head placed an order for Lithium Ion Battery tester for power banks5 hours ago

Operations Head placed an order for Lithium Ion Battery tester for power banks5 hours ago Lead Purchaser requested specs for Electronics And Automobile Material Test Rain Spray Test Chamber2025-12-12 23:29:17

Lead Purchaser requested specs for Electronics And Automobile Material Test Rain Spray Test Chamber2025-12-12 23:29:17 Procurement Lead inquired about 20KN Plastic Pipe PVC PP PE Tube Ring Stiffness Pressure Strength Testing Machine2025-12-15 08:39:37

Procurement Lead inquired about 20KN Plastic Pipe PVC PP PE Tube Ring Stiffness Pressure Strength Testing Machine2025-12-15 08:39:37 Importer is sourcing Digital Thickness Tester Iso5084 Astm D1777 Thickness Meter2025-12-12 13:04:44

Importer is sourcing Digital Thickness Tester Iso5084 Astm D1777 Thickness Meter2025-12-12 13:04:44 Wholesale Short Silicone Test Drip Tips for Ecigs/electronic Cigarette Using Best Material Disposable Silicone Drip Tip CoverUS$ 1.5 - 1.8MOQ: 10 PiecesPlace of Origin: Guangdong, ChinaBrand Name: moosnoonModel Number: AC1052Shenzhen Moonsoon Trading Co., Ltd.5 Yrs

Wholesale Short Silicone Test Drip Tips for Ecigs/electronic Cigarette Using Best Material Disposable Silicone Drip Tip CoverUS$ 1.5 - 1.8MOQ: 10 PiecesPlace of Origin: Guangdong, ChinaBrand Name: moosnoonModel Number: AC1052Shenzhen Moonsoon Trading Co., Ltd.5 Yrs Tianjin Factory Supply S-style 2'x6'4'' 2'x5'' Narrow Frame Type Scaffolding Construction Materials SGS TestUS$ 15 - 30MOQ: 600 PiecesPlace of Origin: Tianjin, ChinaBrand Name: ADTO, ADTOModel Number: AD-WT564Tianjin Heshunchang Scaffolding Co., Ltd.5 Yrs

Tianjin Factory Supply S-style 2'x6'4'' 2'x5'' Narrow Frame Type Scaffolding Construction Materials SGS TestUS$ 15 - 30MOQ: 600 PiecesPlace of Origin: Tianjin, ChinaBrand Name: ADTO, ADTOModel Number: AD-WT564Tianjin Heshunchang Scaffolding Co., Ltd.5 Yrs Air Purifier and Material Test System, Air Purifier Material Test System Factory, Air Purifier Material Test MachineUS$ 30000 - 60000MOQ: 1 SetBrand Name: SimplewellPlace of Origin: ChinaSimplewell Technology Co., LTD

Air Purifier and Material Test System, Air Purifier Material Test System Factory, Air Purifier Material Test MachineUS$ 30000 - 60000MOQ: 1 SetBrand Name: SimplewellPlace of Origin: ChinaSimplewell Technology Co., LTD Compression Plates Shoes Material Testing EquipmentUS$ 2000 - 3000MOQ: 1 SetBrand Name: Serve RealPlace of Origin: ChinaModel Number: Serve RealPower: ElectronicWuxi Serve Real Technology Co., Ltd.

Compression Plates Shoes Material Testing EquipmentUS$ 2000 - 3000MOQ: 1 SetBrand Name: Serve RealPlace of Origin: ChinaModel Number: Serve RealPower: ElectronicWuxi Serve Real Technology Co., Ltd. Gopoint Tensile Tester Universal Material Testing MachineUS$ 15000 - 100000MOQ: 1 SetBrand Name: GOPOINTPlace of Origin: ChinaModel Number: GP-S2000MPower: ElectronicGopoint Testing Equipment Co.,ltd

Gopoint Tensile Tester Universal Material Testing MachineUS$ 15000 - 100000MOQ: 1 SetBrand Name: GOPOINTPlace of Origin: ChinaModel Number: GP-S2000MPower: ElectronicGopoint Testing Equipment Co.,ltd Dental Material Testing Machine,Adhesive Bond TesterUS$ 9988MOQ: 1 CaseType: Strength Testing MachineWarranty: 3yearWeight: 100-500KgPower Source: AC220VJinan Start Testing Technology Co., Ltd

Dental Material Testing Machine,Adhesive Bond TesterUS$ 9988MOQ: 1 CaseType: Strength Testing MachineWarranty: 3yearWeight: 100-500KgPower Source: AC220VJinan Start Testing Technology Co., Ltd