Industrial Joystick Control Insights & Buyer's Guide

When it comes to industrial functions, accuracy and control are exceedingly important. This is where the modern joystick controller comes into play. These multi-axis controllers allow effortless command control, letting an operator execute intricate movements with a simple wrist twist. Whether you're controlling a crane, operating heavy machinery, or configuring a custom joystick for an industrial application, the appropriate joystick can enhance both effectiveness and safety, providing maximum results in daily operations.

What is an Industrial Joystick Controller?

Exploring and Learning with Multi-Axis for Examination Purpose in Joysticks

An industrial joystick controller is not just an input device, but rather it is the very center for commanding multi-function heavy-duty applications. Multi-axis joysticks are constructed for operations where more than one directional input is required to be preformed at the same time. This feature makes them very appropriate for tasks that require careful and fine movements. Whereas multi-axis joysticks provide an expanded envelope of intuitive joysticks controllers three dimensional experience better than single joysticks with their straight forward deflection along single horizontal or vertical plane.

What is an Industrial Joystick Used For Enhancing Machinery

Integration of joystick with industrial machinery is essential from both operational economic efficiency and safety standpoints. Joysticks give operators the ability to gently and accurately execute movements of any crane, which makes these devices operate much faster. Implements of industry controllers have options with required modification, control, id, sensitivity, output, to any required scope. Each provided movement is executed smoothly controllable and accurate in the limits of ranges and control over the manipulator.

Types of Industrial Joystick Controllers: Single Axis vs Multi Axis

Broadly speaking, industrial joystick controllers single-axis and multi-axis categories. Single-axis joysticks are simple as they only permit control over a single linear movement direction useful in situations where motion can go in two or three directions only. In contrast, multi-axis joysticks allow for a greater degree of movement and are essential for advanced machinery which needs complex movement. Knowing the number of axes that a specific industrial controller has is important because selecting the right one can enhance operational effectiveness and flexibility.

How to Choose the Right Multi-Axis Joystick for Your Needs?

Key Features to Look for in an Industrial Joystick

Consider all features when selecting an industrial joystick. Pay attention to durable materials with IP65 enclosures that protect against water and dust. Potentiometer or hall-effect sensor technology for control has to be considered too. The ergonomics of the device can also be customized by specifying spring return to center with thumb or fingertip controls which enhances user experience.

Benefits of Opting For Hall-Effect Sensor Technology

Benefits include improvement on accuracy and reduction on device wear for hall-effect sensor technology in joystick controllers. Compared to other systems that operate with physical contact like potentiometer-based systems, hall-effect sensors utilizing magnetic fields proves to be more reliable and longer lasting. This is an advantage for multi-axis joysticks which require precise proportional controls for industrial tasks due to their complexity.

Tailoring the Industrial Applications of the Joystick Controller

Adjustment of the joystick controller is imperative to ensure that it fulfills specific industrial application needs. Considerations such as the count of added axes and the choice of thumb controls or fingertip controls determine how well the joystick will integrate into your machinery. JR Merritt is a forerunner in the industry, and they specialize in adjustments ranging from lever shapes to output settings, bolstering efficiency and safety.

Why Are Multi-Axis Joystick Controllers Essential for Crane Operations?

Enhancing safety and precision for flac cranes

When operating a crane, both accuracy and safety must be maintained at all times. Furthermore, multi-axis joystick controllers offer unparalleled control over any set of complex movements, which are typically done with cranes. To ensure smooth and accurate directional corrections in high-risk safety environments, multi-axis controllers facilitate greater control for operators, maintaining a high accuracy level ensuring that the operational safety is elevated.

Multi-axis joystick controls comparison with single axis

For basic functioning of a crane, single axis joysticks is acceptable; however, multi-axis controls are the advanced weapons that allow improved precision and maneuverability. Multi-axis joysticks are capable of more complex and precise tasks with a higher number of coordinated movements achievable concurrently, making them fundamentally more flexible than single axis joysticks. Such capabilities heighten the efficiency in most advanced crane operations while simultaneously ensuring high levels of safety and flexibility with an enhanced sense of control.

Research flac case studies using multi-axis sticks in crane operations

Multi-axis joysticks have dominated the success stories on control devices fitted on cranes. Self-reported company case studies advocated for the implementation of multi-axis joystick solutions due to the superior performance and safety metrics achieved from moving away from using single-axis. The stories shed light on the problem solving capabilities offered in today’s highly productive and reliable control solutions which is sought in skeletal industrial arms found widely in puree demanding industrial settings.

How Do Hall-Effect and Potentiometer Outputs Differ in Joystick Controllers?

The Mechanics of Hall Effect in Industrial Joysticks

Hall-effect technology employs magnetic fields for position detection/magazin position sensing. As such, it provides a highly accurate and durable solution for joystick controllers. This type of technology frees up a tremendous amount of friction and wear from the potentiometer design, which is an advantage in heavy-duty industrial applications where reliability and longevity are crucial.

Pros and Cons of Potentiometer-Based Joystick Controllers

Potentiometer based systems remain popular due to low cost and ease of use. They do, however, pose problems because potentiometers rely heavily upon contact with one another. A drawback that evolves due to everyday contact is inaccuracy and wear. Hall effect sensors do tend to last longer with more precision compared to potentiometers, making them a better option for demanding applications that require excellent control.

Which Output Is Best for Multi-Axis Joystick Applications?

The choice of output technology for multi-axis joystick applications should be based on specific industrial requirements and surrounding parameters. While Hall effect sensors are more accurate and more durable, some may consider potentiometers in less demanding environments where cost is a driving factor. These elements ensure the chosen joystick meets operations performance and reliability standards.

What Are the Advantages of Using JS5 Industrial Controller?

Integration Capabilities of the JS5 Contoller with Industrial Systems.

The controller of the JS5 industrial system is unique with regard to its integration fliexibility as it can be easily automated into many industrial systems. Its input and output configuration is made in a way that it may serve as a control solution on many levels, thus increasing modularity. Integration within preexisting systems enhances joystick controller value from an investment perspective for many businesses that seek to upgrade or replace the joystick controller that they have.

Enhancing user experience with controls located at the thumb and fingertip.

As JS5 controllers enhance user experience by designing thumb and fingertip controls that can be tailored to different users, operators fingers can be rested such that it is ergonometric, adding fingure tip finesse. The meticulous posture allows operator fatigue to be low during prolonged shifts, but working with complex movements industrial environments is easier.

Why choose JS5 when seeking proportional control solutions?

The JS5 industrial controller stands out because of the unparalleled elegance combined with control magnifed with proportional control for advanced users. While in the restate the context, JS5 surpasses the competition by providing advanced technology that enables nuanced and speed adjustable proportional output which is essential for variable output. This ensures dependable output across numerous industrial settings.

Frequently Asked Questions (FAQs)

Q: What is a multi axis joystick?

A: A multi axis joystick is a control device that allows simultaneous control across multiple axes, providing intuitive control for complex machinery and control systems.

Q: How does a dual axis joystick work?

A: A dual axis joystick works by providing control over two separate axes, typically X and Y. This allows for precise control over movements, making it suitable for applications like heavy machinery and agricultural machinery.

Q: What are the benefits of using a hall effect joystick?

A: Hall effect joysticks offer contactless control, which enhances durability and precision. This technology is ideal for heavy duty industrial applications due to its longevity and reliability.

Q: What industries typically use heavy duty industrial joysticks?

A: Heavy duty industrial joysticks are commonly used in industries requiring robust control systems, such as construction, mining, and agricultural machinery, where reliable and durable controls are essential.

Q: How do single axis joystick controls differ from multi axis models?

A: Single axis joystick controls provide movement along one axis, offering simplicity and precision for specific tasks, whereas multi axis models offer more complex control for handling movements in multiple directions.

Q: What is the significance of IP65 in joystick controllers?

A: IP65 rating indicates that the joystick controller is dust-tight and protected against water jets. This makes it suitable for use in harsh environments, ensuring the joystick's durability and performance.

Q: Can joystick controllers be custom configured?

A: Yes, joystick controllers can be custom configured to meet specific requirements, including different handle travel distances, buttons and switches, and other design preferences to suit various applications.

Industrial ORP Transmitter for Chemical Process Control and Water ManagementNegotiableMOQ: 1 PieceTransport Package: Export packagingOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr

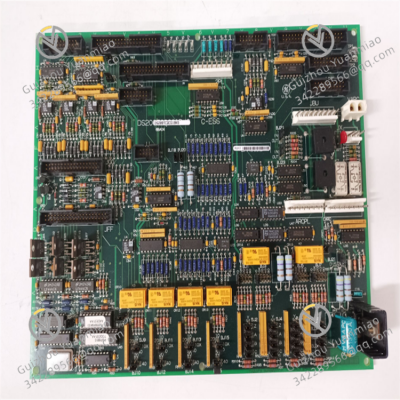

Industrial ORP Transmitter for Chemical Process Control and Water ManagementNegotiableMOQ: 1 PieceTransport Package: Export packagingOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr DS200TCQCG1BKG Industrial Control ModuleNegotiableMOQ: 1 PieceMaterial: Other, Global universal modelCondition: Other, Global universal modelTask: Other, Global universal modelMathematical Model: Other, Global universal modelGuizhou Yuanmiao Automation Equipment Co., Ltd.1 Yr

DS200TCQCG1BKG Industrial Control ModuleNegotiableMOQ: 1 PieceMaterial: Other, Global universal modelCondition: Other, Global universal modelTask: Other, Global universal modelMathematical Model: Other, Global universal modelGuizhou Yuanmiao Automation Equipment Co., Ltd.1 Yr 5SHY4045L0004 3BHB021400R0002 Industrial Automation ControllerNegotiableMOQ: 1 BagXiamen Xiongba E-commerce Co., LTD1 Yr

5SHY4045L0004 3BHB021400R0002 Industrial Automation ControllerNegotiableMOQ: 1 BagXiamen Xiongba E-commerce Co., LTD1 Yr Excavator Joystick Assy Control Valve 1031700169NegotiableMOQ: 1Jingjiang Fuji Technology Co., Ltd.4 Yrs

Excavator Joystick Assy Control Valve 1031700169NegotiableMOQ: 1Jingjiang Fuji Technology Co., Ltd.4 Yrs Industrial Fan Stand Fan With Remote Control-FS45-C(Wechat:13510231336)NegotiableMOQ: 2000 PiecesCertification: ROHS, CEDHome Electric Co,.ltd1 Yr

Industrial Fan Stand Fan With Remote Control-FS45-C(Wechat:13510231336)NegotiableMOQ: 2000 PiecesCertification: ROHS, CEDHome Electric Co,.ltd1 Yr Industrial Safety Equipment: Gas Control Panel Cabinet With Automatic Detection Function for Controlled Gas Flow for Data Centers .US$ 90 - 500MOQ: 5 CombosMaterial: Other, steelType: Gas CabinetColor: Other, yellow /whiteUsage: Hospital, School, Company, Research InstituteLuoyang Hengna Office Furniture Co., Ltd.1 Yr

Industrial Safety Equipment: Gas Control Panel Cabinet With Automatic Detection Function for Controlled Gas Flow for Data Centers .US$ 90 - 500MOQ: 5 CombosMaterial: Other, steelType: Gas CabinetColor: Other, yellow /whiteUsage: Hospital, School, Company, Research InstituteLuoyang Hengna Office Furniture Co., Ltd.1 Yr Industrial Bridge Tractor With Dual Control Systems (Panel & Remote) for Precision Cable ManagementUS$ 2500.00MOQ: 1 AcreApplication: Other, Cable laying in bridges, tunnels, racksMaterial: High-strength steel frameDimensions: Approx. 2020×1570×1170mm (customizable)Control System: Dual control: Panel + RemoteGoldsupplier Tests Store4 Yrs

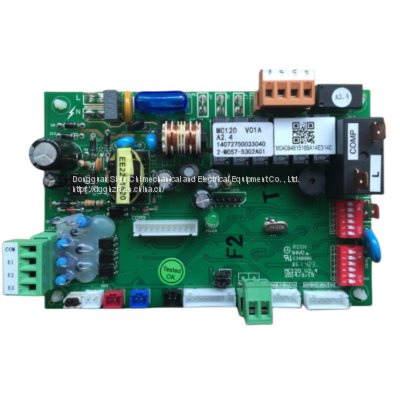

Industrial Bridge Tractor With Dual Control Systems (Panel & Remote) for Precision Cable ManagementUS$ 2500.00MOQ: 1 AcreApplication: Other, Cable laying in bridges, tunnels, racksMaterial: High-strength steel frameDimensions: Approx. 2020×1570×1170mm (customizable)Control System: Dual control: Panel + RemoteGoldsupplier Tests Store4 Yrs RFC400TX Frequency Conversion Board 003E6867 Drive Board for Air Conditioner Outdoor Unit of Haier Multi-unit of Mitsubishi Heavy IndustryCNY 600 - 2800MOQ: 1 PieceBrand Name: Mitsubishi Heavy IndustryPlace of Origin: ChinaModel Number: RFC400TX frequency conversion board 003E6867 drive board for air conditioner outdoor unit of Haier multi-unit of Mitsubishi Heavy IndustryCertification: ULDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs

RFC400TX Frequency Conversion Board 003E6867 Drive Board for Air Conditioner Outdoor Unit of Haier Multi-unit of Mitsubishi Heavy IndustryCNY 600 - 2800MOQ: 1 PieceBrand Name: Mitsubishi Heavy IndustryPlace of Origin: ChinaModel Number: RFC400TX frequency conversion board 003E6867 drive board for air conditioner outdoor unit of Haier multi-unit of Mitsubishi Heavy IndustryCertification: ULDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs Industrial Foam Hot Melt Machine 220V With PLC Control for Bonding ApplicationsNegotiableMOQ: 1 SetVoltage: 220V ACControl System: PLC ControlApplication: Foam Adhesive BondingMaterial: Stainless Steel ConstructionHenan Panqi Heavy Industry Technology Co., Ltd.1 Yr

Industrial Foam Hot Melt Machine 220V With PLC Control for Bonding ApplicationsNegotiableMOQ: 1 SetVoltage: 220V ACControl System: PLC ControlApplication: Foam Adhesive BondingMaterial: Stainless Steel ConstructionHenan Panqi Heavy Industry Technology Co., Ltd.1 Yr Computer-controlled Manhole Tester 1000kN Industrial Manhole Cover Testing MachineUS$ 10000 - 30000MOQ: 1 SetBrand Name: wangtebeiPlace of Origin: ChinaModel Number: WTJPower: HydraulicJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr

Computer-controlled Manhole Tester 1000kN Industrial Manhole Cover Testing MachineUS$ 10000 - 30000MOQ: 1 SetBrand Name: wangtebeiPlace of Origin: ChinaModel Number: WTJPower: HydraulicJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr Industrial Dehumidifier Best Quality Machine Humidity Control Dehumidifier For IndustryNegotiableMOQ: 1 PiecePlace of Origin: ChinaType: Refrigerative DehumidifierFunction: Adjustable Humidistat, Automatic Humidistat ControlXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs

Industrial Dehumidifier Best Quality Machine Humidity Control Dehumidifier For IndustryNegotiableMOQ: 1 PiecePlace of Origin: ChinaType: Refrigerative DehumidifierFunction: Adjustable Humidistat, Automatic Humidistat ControlXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs 9905A Industrial Intelligent Temperature Controller ThermostatUS$ 140.76MOQ: 2 PiecesWarranty: 2 YearsAfter-sale Service: Online Technical Support, Return and ReplacementMaterial: Anti-flammable PC +ABSProject Solution Capability: graphic design, 3D model design, total solution for projects, Cross Categories ConsolidationAnhui Youyu Electric Heating Equipment Co., Ltd.1 Yr

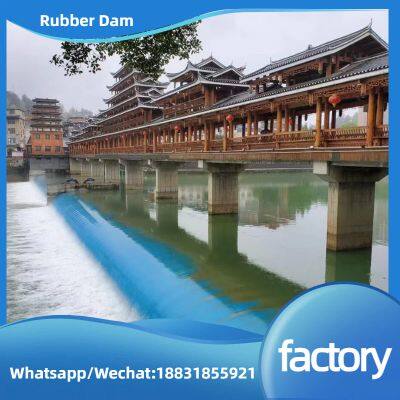

9905A Industrial Intelligent Temperature Controller ThermostatUS$ 140.76MOQ: 2 PiecesWarranty: 2 YearsAfter-sale Service: Online Technical Support, Return and ReplacementMaterial: Anti-flammable PC +ABSProject Solution Capability: graphic design, 3D model design, total solution for projects, Cross Categories ConsolidationAnhui Youyu Electric Heating Equipment Co., Ltd.1 Yr Versatile Inflatable Rubber Dam for Water Diversion and Control in Multiple Industry ScenariosUS$ 190 - 300MOQ: 20 MetersMaterial: Other, Reinforced RubberDimensions: Customizable as per requirementApplication: Water Diversion, Flood ControlCertification: QS9000, ISO9001, ISO9004Hengshui Haogu Engineering Materials Co., Ltd.1 Yr

Versatile Inflatable Rubber Dam for Water Diversion and Control in Multiple Industry ScenariosUS$ 190 - 300MOQ: 20 MetersMaterial: Other, Reinforced RubberDimensions: Customizable as per requirementApplication: Water Diversion, Flood ControlCertification: QS9000, ISO9001, ISO9004Hengshui Haogu Engineering Materials Co., Ltd.1 Yr Industrial 48 Tray Steam Rice Cooker With Digital Temperature ControlNegotiableMOQ: 1 SetType: Other, Steam ovenWarranty: a yearVoltage: Other, 220V-380VUsage: Biscuit, Cake, Pizza, BreadJinan Xinyuqi Food Machinery Co., Ltd.1 Yr

Industrial 48 Tray Steam Rice Cooker With Digital Temperature ControlNegotiableMOQ: 1 SetType: Other, Steam ovenWarranty: a yearVoltage: Other, 220V-380VUsage: Biscuit, Cake, Pizza, BreadJinan Xinyuqi Food Machinery Co., Ltd.1 Yr Fermentation Control Industrial Beer Making Equipment For Laboratory RoomNegotiableMOQ: 1 SetCertification: Other, CE, UL,ISOWarranty: 1 YearApplication: OtherAutomatic Grade: AutomaticShandong Gongda Intelligent Equipment Co., Ltd.1 Yr

Fermentation Control Industrial Beer Making Equipment For Laboratory RoomNegotiableMOQ: 1 SetCertification: Other, CE, UL,ISOWarranty: 1 YearApplication: OtherAutomatic Grade: AutomaticShandong Gongda Intelligent Equipment Co., Ltd.1 Yr Industrial Fruit Juice Extractor 4.0 Kw Plc ControlledUS$ 19000 - 24000MOQ: 1 SetAfter-sales Service Provided: Engineers available to service machinery overseasWarranty: One YearCertification: ISO CEDimension(L*W*H): 1900*670*1695mmHenan Gelgoog Machinery CO,LTD2 Yrs

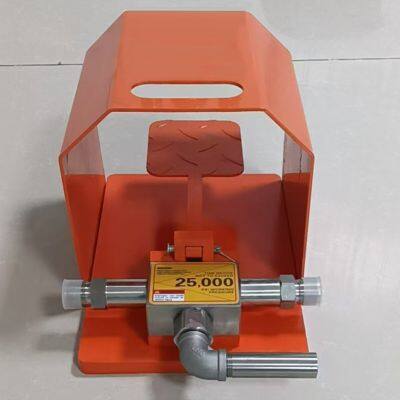

Industrial Fruit Juice Extractor 4.0 Kw Plc ControlledUS$ 19000 - 24000MOQ: 1 SetAfter-sales Service Provided: Engineers available to service machinery overseasWarranty: One YearCertification: ISO CEDimension(L*W*H): 1900*670*1695mmHenan Gelgoog Machinery CO,LTD2 Yrs Ultra High Pressure Foot Control Valve Industry Pipe Cleaning Control Valve Overflow Hydro Jetting ValveUS$ 280.00 - 380.00MOQ: 1 Piecewarranty: 3 Monthsweight (kg): 2place of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr

Ultra High Pressure Foot Control Valve Industry Pipe Cleaning Control Valve Overflow Hydro Jetting ValveUS$ 280.00 - 380.00MOQ: 1 Piecewarranty: 3 Monthsweight (kg): 2place of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr Electronic Industrial Control Electrical Machine Air Automatic Computer Crimp Cable AssemblyNegotiableMOQ: 1 UnitType: InsulatedInsulation Material: PVCConductor Material: CopperConductor Type: StrandedGusu District Qiusheng Commercial Equipment Firm1 Yr

Electronic Industrial Control Electrical Machine Air Automatic Computer Crimp Cable AssemblyNegotiableMOQ: 1 UnitType: InsulatedInsulation Material: PVCConductor Material: CopperConductor Type: StrandedGusu District Qiusheng Commercial Equipment Firm1 Yr Precision Cut TC10 Titanium Alloy Bar High-Accuracy Titanium Rod for Industrial Control PartsNegotiableMOQ: 100 KilogramsSurface Treatment: Other, Bright rodShape: BarColor: SilverMaterial: Other, TitaniumWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr

Precision Cut TC10 Titanium Alloy Bar High-Accuracy Titanium Rod for Industrial Control PartsNegotiableMOQ: 100 KilogramsSurface Treatment: Other, Bright rodShape: BarColor: SilverMaterial: Other, TitaniumWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr Industrial Water Flowserve Stainless Steel Pneumatic Cylinder Port Flow Control ValveNegotiableMOQ: 100 PiecesApplication: Industrial Usage, Water Industrial Usage, Household UsagePressure: Other, PN10,PN16Production Size: DN50-600Design Standard: DIN3352Chengxin Valve Co., Ltd.1 Yr

Industrial Water Flowserve Stainless Steel Pneumatic Cylinder Port Flow Control ValveNegotiableMOQ: 100 PiecesApplication: Industrial Usage, Water Industrial Usage, Household UsagePressure: Other, PN10,PN16Production Size: DN50-600Design Standard: DIN3352Chengxin Valve Co., Ltd.1 Yr Automatic Lifting Lighting Device XD-354500 With Remote Control for Industrial Construction & Emergency RescueNegotiableMOQ: 1 SetMaterial: AluminumCertification: ISOUsage: Fire Lights, Traffic lightsColor Temperature: Pure WhiteShanghai Hesheng Safety Equipment Co., Ltd.1 Yr

Automatic Lifting Lighting Device XD-354500 With Remote Control for Industrial Construction & Emergency RescueNegotiableMOQ: 1 SetMaterial: AluminumCertification: ISOUsage: Fire Lights, Traffic lightsColor Temperature: Pure WhiteShanghai Hesheng Safety Equipment Co., Ltd.1 Yr Purchaser is sourcing High temperature digital controlled Industrial drying oven2025-12-21 07:47:49

Purchaser is sourcing High temperature digital controlled Industrial drying oven2025-12-21 07:47:49 Sourcing Agent requested specs for Training Model, Industrial Process Control Training Device16 hours ago

Sourcing Agent requested specs for Training Model, Industrial Process Control Training Device16 hours ago Import Coordinator submitted an RFQ for Industrial air shower with removing dust Photoelectric control2025-12-23 14:10:14

Import Coordinator submitted an RFQ for Industrial air shower with removing dust Photoelectric control2025-12-23 14:10:14 Verified Buyer requested specs for industry sprayer coal dust control8 hours ago

Verified Buyer requested specs for industry sprayer coal dust control8 hours ago Operations Head negotiating terms for 12v dc gsm wireless remote controller switch/industrial remote controller2025-12-19 19:59:57

Operations Head negotiating terms for 12v dc gsm wireless remote controller switch/industrial remote controller2025-12-19 19:59:57 Procurement Specialist is sourcing Industrial Conductivity Controller on sale2025-12-20 08:44:34

Procurement Specialist is sourcing Industrial Conductivity Controller on sale2025-12-20 08:44:34 Sourcing Manager verified certifications for industry controller pcba, industry pcba, industry assembly2025-12-19 20:50:58

Sourcing Manager verified certifications for industry controller pcba, industry pcba, industry assembly2025-12-19 20:50:58 Buyer requested a quote for easy control industrial wool washing machine2025-12-18 20:07:30

Buyer requested a quote for easy control industrial wool washing machine2025-12-18 20:07:30 Industrial-Grade Explosive-Proof OGI Camera With VOx Detector and Manual Focus ControlNegotiableMOQ: 50 PiecesCertification: FCCWarranty: 1 yearBrand: OtherAfter-sales Service: supportRaythink Technology Co., Ltd.2 Yrs

Industrial-Grade Explosive-Proof OGI Camera With VOx Detector and Manual Focus ControlNegotiableMOQ: 50 PiecesCertification: FCCWarranty: 1 yearBrand: OtherAfter-sales Service: supportRaythink Technology Co., Ltd.2 Yrs Precision Replace 828801 - 7 22 - Pin PCB Header Connector for Industrial Control SystemsUS$ 0.1 - 1MOQ: 10 PiecesApplication: AutomotiveGender: MaleTransport Package: StandardSpecification: StandardZhejiang Longsun Electric Co.,Ltd1 Yr

Precision Replace 828801 - 7 22 - Pin PCB Header Connector for Industrial Control SystemsUS$ 0.1 - 1MOQ: 10 PiecesApplication: AutomotiveGender: MaleTransport Package: StandardSpecification: StandardZhejiang Longsun Electric Co.,Ltd1 Yr Changyun Jiangniu 2, Honghuang Edition Cable Conveyor, Industrial Cable Conveyor, Custom Voltage, Multi-Gear Speed, Panel & Remote ControlUS$ 1500 - 1600MOQ: 1 ComboType: Other, Cable thrustersCertification: CE, CCC, ISOFeature: MoistureproofCondition: NewZhengzhou Zhishichangyun Technology Co. Ltd.1 Yr

Changyun Jiangniu 2, Honghuang Edition Cable Conveyor, Industrial Cable Conveyor, Custom Voltage, Multi-Gear Speed, Panel & Remote ControlUS$ 1500 - 1600MOQ: 1 ComboType: Other, Cable thrustersCertification: CE, CCC, ISOFeature: MoistureproofCondition: NewZhengzhou Zhishichangyun Technology Co. Ltd.1 Yr High Impact Industrial Pure Iron Cold-Drawn Bar 160-200 J/cm² DT4C Wire for Aircraft Control PartsNegotiableMOQ: 1 TonType: Other, Electromagnetic Pure Iron Hot Rolled Round SteelTechnique: Hot RolledOrigin: Taiyuan, Shanxi, ChinaShanxi Juli Run Technology Co., Ltd.1 Yr

High Impact Industrial Pure Iron Cold-Drawn Bar 160-200 J/cm² DT4C Wire for Aircraft Control PartsNegotiableMOQ: 1 TonType: Other, Electromagnetic Pure Iron Hot Rolled Round SteelTechnique: Hot RolledOrigin: Taiyuan, Shanxi, ChinaShanxi Juli Run Technology Co., Ltd.1 Yr Controller JoystickNegotiableMOQ: 10 PiecesBrand Name: mikkoCompatible Platform: PS2Type: JoystickPlace of Origin: Guangdong, ChinaGuangzhou Weihui Electronic Co., Ltd.5 Yrs

Controller JoystickNegotiableMOQ: 10 PiecesBrand Name: mikkoCompatible Platform: PS2Type: JoystickPlace of Origin: Guangdong, ChinaGuangzhou Weihui Electronic Co., Ltd.5 Yrs Joystick Control Detection Tool Industrial Borescope Videoscope Endoscope OD10MMUS$ 680 - 1,500MOQ: 1 UnitBrand Name: NGModel Number: MIGS10100VGAPower: ElectronicUsage: Auto Testing MachineYunhe Qiaoda Technology Co., Ltd.5 Yrs

Joystick Control Detection Tool Industrial Borescope Videoscope Endoscope OD10MMUS$ 680 - 1,500MOQ: 1 UnitBrand Name: NGModel Number: MIGS10100VGAPower: ElectronicUsage: Auto Testing MachineYunhe Qiaoda Technology Co., Ltd.5 Yrs HOLDWELL Joystick Controllers 113P319030US$ 20 - 40MOQ: 1 PieceBrand Name: HOLDWELLPlace of Origin: Zhejiang, ChinaModel Number: 113P319030Hangzhou Holdwell Mechanical And Electrical Co., Ltd.5 Yrs

HOLDWELL Joystick Controllers 113P319030US$ 20 - 40MOQ: 1 PieceBrand Name: HOLDWELLPlace of Origin: Zhejiang, ChinaModel Number: 113P319030Hangzhou Holdwell Mechanical And Electrical Co., Ltd.5 Yrs