Poly Woven Bulk Bag Liners With High Tensile Strength for Construction Materials

Xuzhou Guozi Intelligent Technology Co., Ltd., a trusted manufacturer based in Jiangsu, China, specializes in premium bulk material handling solutions. Our Poly Woven Bulk Bag Liners represent the pinnacle of protective packaging technology for construction materials. Engineered with high tensile strength polypropylene, these liners ensure your valuable aggregates, powders, and building compounds remain contamination-free throughout storage and transportation.

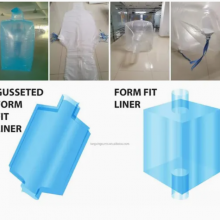

These innovative liners are specifically designed to withstand the demanding conditions of construction sites while providing maximum product integrity. The tear-resistant construction prevents material loss during handling operations, while the precisely engineered dimensions ensure perfect compatibility with standard bulk containers. With customizable options available, we deliver solutions that precisely match your operational requirements.

Core Technical Specifications:

| Parameter | Specification | Benefit |

|---|---|---|

| Material Composition | High-density polypropylene | Superior puncture resistance |

| Tensile Strength | Customizable up to 50 kN/m | Handles heavy construction materials |

| Standard Thickness | 80-150 gsm | Optimal balance of strength and weight |

| Seam Construction | Double-stitched or heat-sealed | Prevents seam failure under load |

| Temperature Tolerance | -20°C to 80°C | Suitable for various climates |

Operational Advantages:

- • Moisture Barrier Protection: Special coating options create an impermeable layer that safeguards hygroscopic materials from humidity degradation

- • Static Dissipation: Available conductive variants prevent dangerous static buildup when handling combustible construction powders

- • Custom Sizing: Precisely engineered to match your existing bulk containers with millimeter accuracy

- • Quick-Load Design: Wide-mouth openings reduce filling time by up to 40% compared to standard liners

- • Reusable Options: Reinforced construction allows multiple uses for cost-sensitive applications

These liners deliver measurable benefits throughout your supply chain. Construction material producers report up to 99.5% product retention during transit, significantly reducing material loss. The smooth inner surface facilitates complete discharge of viscous materials like cement additives, while the anti-slip exterior prevents shifting during transport. Our manufacturing process incorporates rigorous quality checks at three critical stages to ensure every liner meets exacting performance standards.

Frequently Asked Questions:

-

Q: What is the maximum capacity these liners can handle?

A: Our standard liners accommodate up to 2,000 kg, with custom designs available for higher capacities upon request. -

Q: Are these liners suitable for food-grade applications?

A: While primarily designed for construction materials, food-grade variants can be manufactured using specialized polypropylene compounds. -

Q: How do I determine the correct size for my bulk bags?

A: We provide detailed measurement guides and offer complimentary sizing consultation services to ensure perfect compatibility. -

Q: What closure systems are available?

A: Options include heat-sealed bottoms with tie-top closures, drawstring configurations, or specialized spout designs for pneumatic filling systems. -

Q: Can liners be printed with identification markings?

A: Yes, we offer custom printing services for batch numbers, safety warnings, or company logos using non-toxic inks. -

Q: What is the typical lead time for custom orders?

A: Standard production requires 15-20 business days, with expedited services available for urgent requirements.

With over a decade of manufacturing expertise in Jiangsu's industrial heartland, Xuzhou Guozi Intelligent Technology has become a preferred partner for construction material suppliers across Asia. Our commitment to precision engineering ensures that every liner delivers consistent performance under demanding site conditions. The proprietary weaving technique we employ creates a dimensional stability that prevents liner collapse during filling operations, while the UV-stabilized material formulation maintains integrity during outdoor storage.

Experience the difference that purpose-engineered containment makes to your material handling operations. Contact our technical team today to discuss your specific requirements and discover how our bulk bag liners can optimize your logistics while reducing product loss. We offer comprehensive sample programs and volume-based pricing structures designed for bulk material handlers.

Send Inquiry to This Supplier

You May Also Like

-

Conductive FIBC Bulk Bag Liner for Explosive Dust Environments and SafetyNegotiableMOQ: 1000 Pieces

-

Custom Size FIBC Bulk Bag Liner for Industrial Chemicals and Hazardous MaterialsNegotiableMOQ: 1000 Pieces

-

Recyclable Polyethylene FIBC Bulk Bag Liner for Agricultural Products ProtectionNegotiableMOQ: 1000 Pieces

-

Extra Strength FIBC Bulk Bag Liner for Heavy-Duty Construction MaterialsNegotiableMOQ: 1000 Pieces

-

FIBC Bulk Bag Inner Liner, PP Woven Material, Custom Sizes Available, Ideal for Grain and Powder TransportNegotiableMOQ: 500 Pieces

-

Heavy-Duty FIBC Container Liner, 2000kg Load Capacity, Anti-Static Feature for Safe Material HandlingNegotiableMOQ: 500 Pieces

-

FIBC Jumbo Bag Liner With Spout Top Design, Easy Filling and Sealing, Suitable for Building MaterialsNegotiableMOQ: 500 Pieces

-

Reusable FIBC Bag Inner Liner, UV Resistant, 100-150 Micron Thickness for Outdoor Storage ApplicationsNegotiableMOQ: 500 Pieces

-

Customizable Size FIBC Liner for Construction Industry, Fits Standard Bulk Bags, Dust-Free Cement PackagingNegotiableMOQ: 500 Pieces

-

Food Grade FIBC Liner With FDA Certification, Prevents Contamination in Sugar and Flour TransportationNegotiableMOQ: 500 Pieces