FIBC Bulk Bag Liners Compatible With 1-2 Ton Jumbo Bags for Safe Transport

As a leading manufacturer based in Xuzhou, Jiangsu, Xuzhou Guozi Intelligent Technology Co., Ltd. specializes in producing premium FIBC bulk bag liners designed for secure transportation of dry flowable materials. Our liners ensure product integrity during storage and transit while preventing contamination – a critical solution for industries demanding purity and safety.

Key Features & Technical Specifications:

- Precision Compatibility: Engineered to fit 1-2 ton jumbo bags perfectly, reducing material shifting and bag stress during handling.

- Food-Grade Material: Manufactured using high-clarity polyethylene that meets stringent hygiene requirements for food and pharmaceutical applications.

- Enhanced Seam Integrity: Heat-sealed seams prevent leakage even under heavy loads, with optional double-seaming for abrasive materials.

- Customizable Protection: Available in multiple thicknesses (80-150 microns standard) and sizes to match specific container dimensions.

| Parameter | Standard Specification | Custom Options |

|---|---|---|

| Thickness Range | 80-120 microns | Up to 150 microns |

| Width/Length | Matched to bag dimensions | ±2% tolerance adjustment |

| Top Sealing | Open top with tie options | Ziplock, drawstring |

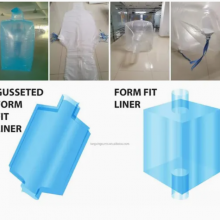

| Bottom Design | Flat construction | Gusseted base |

Operational Advantages:

- Contamination Control: Creates critical barrier against moisture, dust, and foreign particles during filling/discharge.

- Cost Efficiency: Extends FIBC lifespan by preventing residue buildup and reducing cleaning requirements.

- Product Preservation: Maintains moisture-sensitive material integrity (e.g., chemicals, food ingredients) throughout supply chain.

- Quick Installation: Pre-shaped design allows rapid deployment without complex fitting procedures.

With over 10 years of industrial packaging expertise, our Jiangsu manufacturing facility utilizes automated production lines to ensure consistent quality across every liner. We implement rigorous material testing protocols to guarantee tensile strength and puncture resistance suitable for demanding logistics environments.

FAQ Section:

Q: Are these liners suitable for pharmaceutical raw materials?

A: Yes, our polyethylene liners are inert and meet purity requirements for pharmaceutical intermediates when produced in controlled environments upon request.

Q: Can I get printed liners for product identification?

A: Custom printing (lot codes, logos, handling instructions) is available using food-safe inks. Minimum order quantities apply.

Q: How do I determine the correct thickness?

A: Thickness depends on material abrasiveness and filling height. Our technical team provides recommendations based on your product characteristics.

Q: Do you offer anti-static options?

A: Static-dissipative versions are available for combustible powders. Inquire for technical datasheets.

Q: What is the lead time for custom sizes?

A: Standard orders ship in 7-10 days. Customized production typically requires 15 working days after confirmation.

Q: How are liners packaged for shipment?

A: They are compressed and palletized to minimize freight costs. Standard pallet contains 1,000-1,500 liners depending on thickness.

Partner with Xuzhou Guozi for reliable bulk transport solutions. Our responsive engineering team supports tailored liner configurations to optimize your packaging process – contact us today for technical consultation and sample requests.

Send Inquiry to This Supplier

You May Also Like

-

Multi-Layer FIBC Bulk Bag Liner With UV Protection for Outdoor StorageNegotiableMOQ: 1000 Pieces

-

FDA Approved FIBC Bulk Bag Liner for Safe Food and Pharmaceutical PackagingNegotiableMOQ: 1000 Pieces

-

Conductive FIBC Bulk Bag Liner for Explosive Dust Environments and SafetyNegotiableMOQ: 1000 Pieces

-

Custom Size FIBC Bulk Bag Liner for Industrial Chemicals and Hazardous MaterialsNegotiableMOQ: 1000 Pieces

-

Recyclable Polyethylene FIBC Bulk Bag Liner for Agricultural Products ProtectionNegotiableMOQ: 1000 Pieces

-

Extra Strength FIBC Bulk Bag Liner for Heavy-Duty Construction MaterialsNegotiableMOQ: 1000 Pieces

-

FIBC Bulk Bag Inner Liner, PP Woven Material, Custom Sizes Available, Ideal for Grain and Powder TransportNegotiableMOQ: 500 Pieces

-

Heavy-Duty FIBC Container Liner, 2000kg Load Capacity, Anti-Static Feature for Safe Material HandlingNegotiableMOQ: 500 Pieces

-

FIBC Jumbo Bag Liner With Spout Top Design, Easy Filling and Sealing, Suitable for Building MaterialsNegotiableMOQ: 500 Pieces

-

Reusable FIBC Bag Inner Liner, UV Resistant, 100-150 Micron Thickness for Outdoor Storage ApplicationsNegotiableMOQ: 500 Pieces