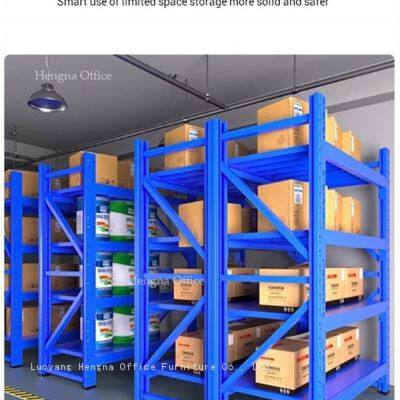

Workshop Organizer Racks HN-F276 for Factory, 500kg Per Level, Wider Welded Feet for High Stability - Industrial Metal Shelving, OEM/ODM

The Workshop Organizer Racks HN-F276

Built specifically for the relentless demands of factory and industrial environments, it delivers unparalleled strength per level and foundational stability, transforming chaotic work areas into models of efficiency and order.

Engineered for Industrial Duty: A Solution Built on Strength

The HN-F276 isn't adapted from a commercial design; it's purpose-built from the ground up for industry. Its design philosophy centers on two non-negotiable principles: massive, reliable load capacity and rock-solid, immovable stability. Every feature, from the steel gauge to the weld points, is specified to handle the daily grind of factory life—forklift vibrations, heavy impact loads, and years of constant use.

How HN-F276 Solves Core Workshop Challenges

This rack directly addresses the most common and costly issues found in factory storage setups. The following table contrasts typical problems with the engineered solutions provided by the HN-F276:

| Typical Workshop Problem | HN-F276 Solution & Feature |

|---|---|

| Shelf Bending or Collapsing under extreme weight. | 500kg Per Level Capacity supported by reinforced laminate with multiple support bars. |

| Units wobbling, rocking, or feeling unsafe when loaded. | Wider Welded Feet provide an expanded footprint. Triangular support at joints eliminates racking. |

| Difficult, time-consuming assembly requiring tools and multiple people. | Boltless Assembly with a secure butterfly hole bayonet system for fast, tool-free setup. |

| Surface rust, corrosion, and paint chipping from chemicals and humidity. | Cold-Rolled Steel with Electrostatic Powder Coating ensures corrosion resistance and durability. |

| Inflexible storage that can't adapt to changing part sizes or workshop layouts. | Adjustable Shelf Heights (on 1" or 2" increments) and a modular design allow for easy reconfiguration. |

1. Unmatched Load-Bearing: The 500kg Per Shelf Promise

The standout feature is its extraordinary 500kg (1,100 lbs) capacity per shelf level. This capability is achieved through a multi-faceted approach:

High-Hardness Cold-Rolled Steel: The primary material offers superior strength-to-weight ratio compared to standard steel.

Structural Laminate Design: Each shelf is a layered panel. Crucially, the underside features multiple, pressed-in reinforcement bars that act like miniature I-beams, distributing weight to the edges and preventing center sag. This means you can store engine blocks, stacks of metal plates, or heavy dies with confidence.

Robust Beam-to-Column Connection: Beams lock into columns via a diamond hole design, creating a shear-proof connection that gets tighter as load increases.

2. Foundation of Stability: Wider Welded Feet & Enhanced Welding

Stability is not an afterthought; it's engineered into the base. The wider welded feet are a critical differentiator.

Increased Leverage & Balance: The expanded base acts like a broader stance, dramatically increasing the unit's resistance to tipping, especially when upper shelves are heavily loaded.

Permanent, Solid Connection: The feet are not bolted on; they are securely welded directly to the vertical columns using enhanced welding technology. This creates a continuous, monolithic structure at the most critical stress point, ensuring "zero wobble" from the ground up.

Aesthetic Durability: The welding is not only strong but also finished to be smooth and aesthetically pleasing, with no sharp spatter or rough edges to snag on or cause injury.

3. Industrial-Grade Construction & Finish

Material Integrity: Built from upgraded and thickened cold-rolled steel, the frame and shelves are designed for a long service life.

Protective Finish: The electrostatic spray painting process applies a uniform, adhesive, and corrosion-resistant coat. It protects against oils, minor chemical spills, and the humid conditions common in factories, preventing rust and maintaining a professional appearance.

Clean Design: The boltless design means no protruding nuts or bolts to snag clothing, hoses, or cables, promoting a safer and cleaner workspace.

4. Practical, User-Friendly Design

Understanding factory workflow is key. The open-sided, adjustable design allows for easy access from multiple sides with carts or forklifts. The main and auxiliary frame system lets you create long, continuous storage lines without unnecessary vertical supports, maximizing accessible space for bulky items.

Technical Specifications at a Glance

Model: HN-F276 Workshop Organizer Rack

Typical Configuration: 4-Tier (Custom tiers available)

Load Capacity: 500kg (1,100 lbs) per shelf level

Key Stability Feature: Wider Welded Feet

Frame Construction: Enhanced Welding Technology

Material: Cold-Rolled Steel, Reinforced Laminate Shelves

Finish: Electrostatic Powder Coating

Assembly: Boltless, Tool-Free

Service: OEM/ODM Customization Available

Ideal for Factory & Workshop Applications

Machine Shops & Fabrication: Storing metal stock, raw materials, and finished parts.

Automotive & Aerospace Manufacturing: Organizing heavy components, tools, and assemblies.

Maintenance & Repair Bays: Holding tools, spare parts, and equipment.

Assembly Line Kitting Areas: Storing bins of components for production.

General Industrial Warehousing: For bulky, heavy items that defy standard shelving.

Frequently Asked Questions (FAQ)

Q1: Is the 500kg per shelf capacity a realistic, safe working load?

A: Yes, absolutely. The 500kg rating is a safe working load limit, not an ultimate failure point. It is determined through rigorous engineering calculations and physical load testing of the complete system—shelves, beams, and connections. Always distribute the weight evenly across the shelf surface for optimal safety.

Q2: How much more stable are the wider welded feet compared to standard shelving?

A: Significantly more stable. The wider feet increase the stability footprint by approximately 30-40% compared to standard designs. This translates directly to a higher resistance to tipping forces, especially important when loading the top shelves or if the rack is accidentally bumped by equipment. The welded (not bolted) connection ensures this stability is permanent.

Q3: Can you customize the dimensions for our specific workshop layout?

A: Yes, as an OEM/ODM manufacturer, customization is our strength. We can tailor the height, width, depth, number of tiers, and even the powder coat color to match your factory's layout and corporate safety color codes. Contact us with your floor plan and requirements for a custom quote.

Build Your Productivity on a Stable Foundation

The Workshop Organizer Racks HN-F276 provides the industrial-strength storage solution that factory floors demand. It eliminates the worries of overloading and instability, allowing you to focus on production, not storage problems. Its robust build and thoughtful design represent a long-term investment in workshop efficiency and safety.

The contact information of the sales manager is shown in the picture below. You can make inquiries directly without waiting.

Send Inquiry to This Supplier

You May Also Like

-

Industrial-Grade Adjustable Shelving Unit With 300kg Load Capacity per Shelf|Hengna OEM FactoryUS$ 1 - 330MOQ: 5 Sets

-

Industrial Storage Rack 400kg Per Tier - Heavy Duty Expandable Shelving System for Warehouse & Manufacturing FacilitiesUS$ 1 - 330MOQ: 5 Sets

-

400kg Capacity Multi-Purpose Industrial Shelving Unit - Versatile Storage Solution for Supermarket, Library & Commercial SpacesUS$ 1 - 330MOQ: 5 Sets

-

Industrial Strength Shelving System 400kg Capacity Per Level - Heavy Duty Supermarket Storage Rack for Retail Space OptimizationUS$ 1 - 330MOQ: 5 Sets

-

400kg Load Capacity Industrial Racking System - Warehouse Heavy Duty Storage Unit With Butterfly Hole Plug-In DesignUS$ 1 - 330MOQ: 5 Sets

-

Multi-Layer Industrial Storage Unit 400kg Per Shelf - Space-Saving Library Shelving Solution With Freely Adjustable LayerUS$ 1 - 330MOQ: 5 Sets

-

Robust Industrial Storage Solution- Heavy Duty Medical Shelving Rack for Hospital Clinics and Healthcare FacilitiesUS$ 1 - 330MOQ: 5 Sets

-

Heavy Duty Steel Shelving Bay 200kg Capacity - Industrial Workshop Storage Rack With Butterfly Snap DesignUS$ 1 - 330MOQ: 5 Sets

-

Heavy Duty Parts Storage Rack 300kg Capacity - Workshop Organizer With Main-Subframe DesignUS$ 1 - 330MOQ: 5 Sets

-

Industrial Parts Shelving System 300kg Load Capacity - Garage Storage Solution With Four Reinforcement BarsUS$ 1 - 330MOQ: 5 Sets